Patents

Literature

32results about How to "Realize intelligent welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-station robot intelligent welding system for pipe piling sheets

InactiveCN105397244ARealize the intelligentization of automatic identification of weld seam informationRealize intelligenceManipulatorWelding accessoriesRobotic systemsHuman–machine interface

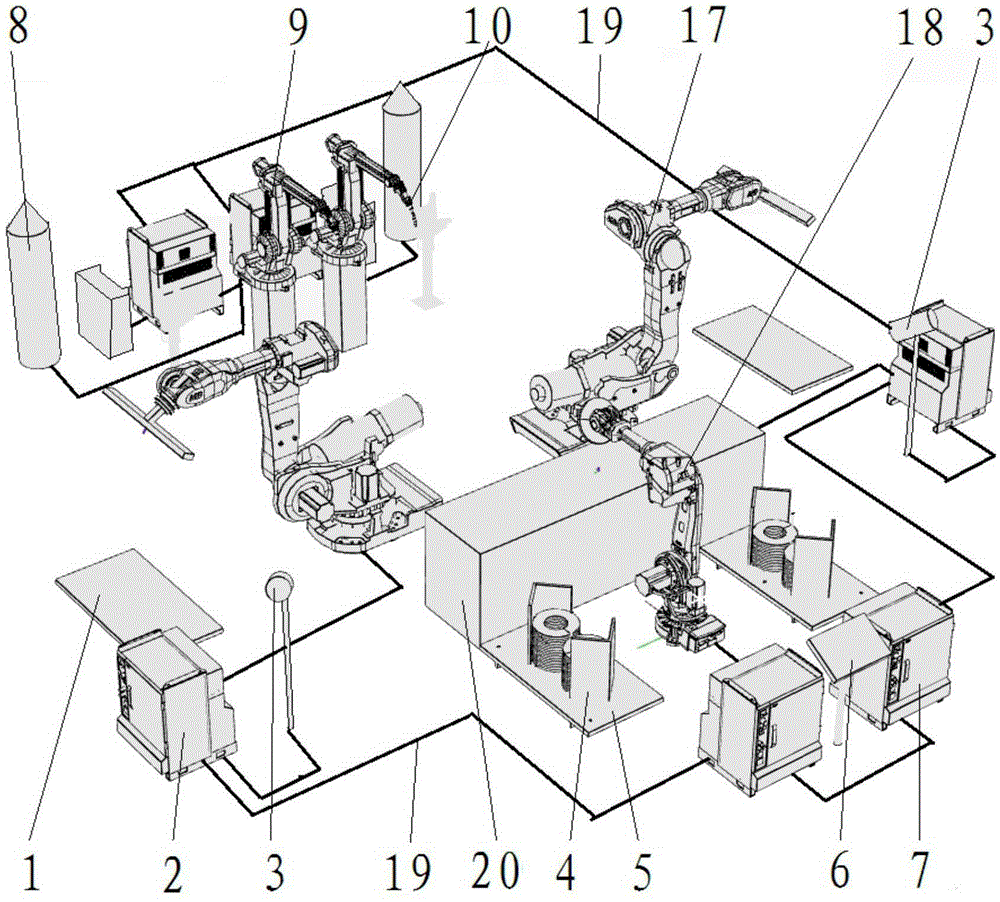

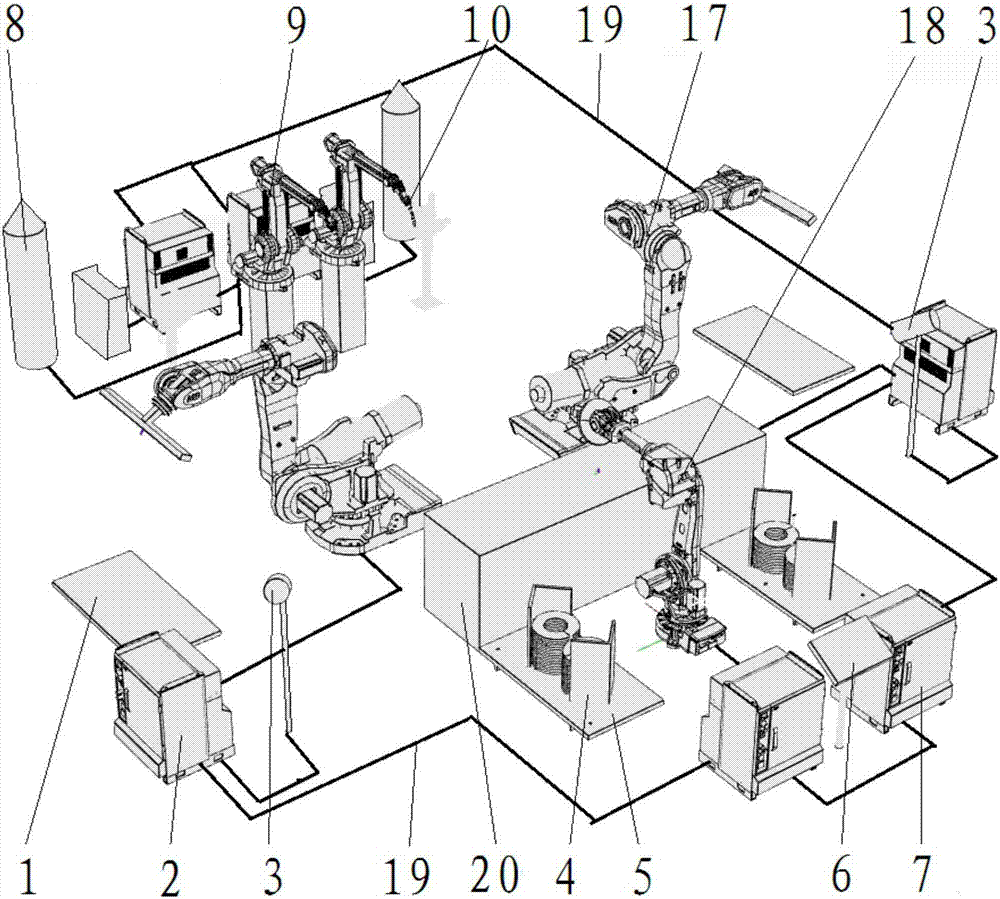

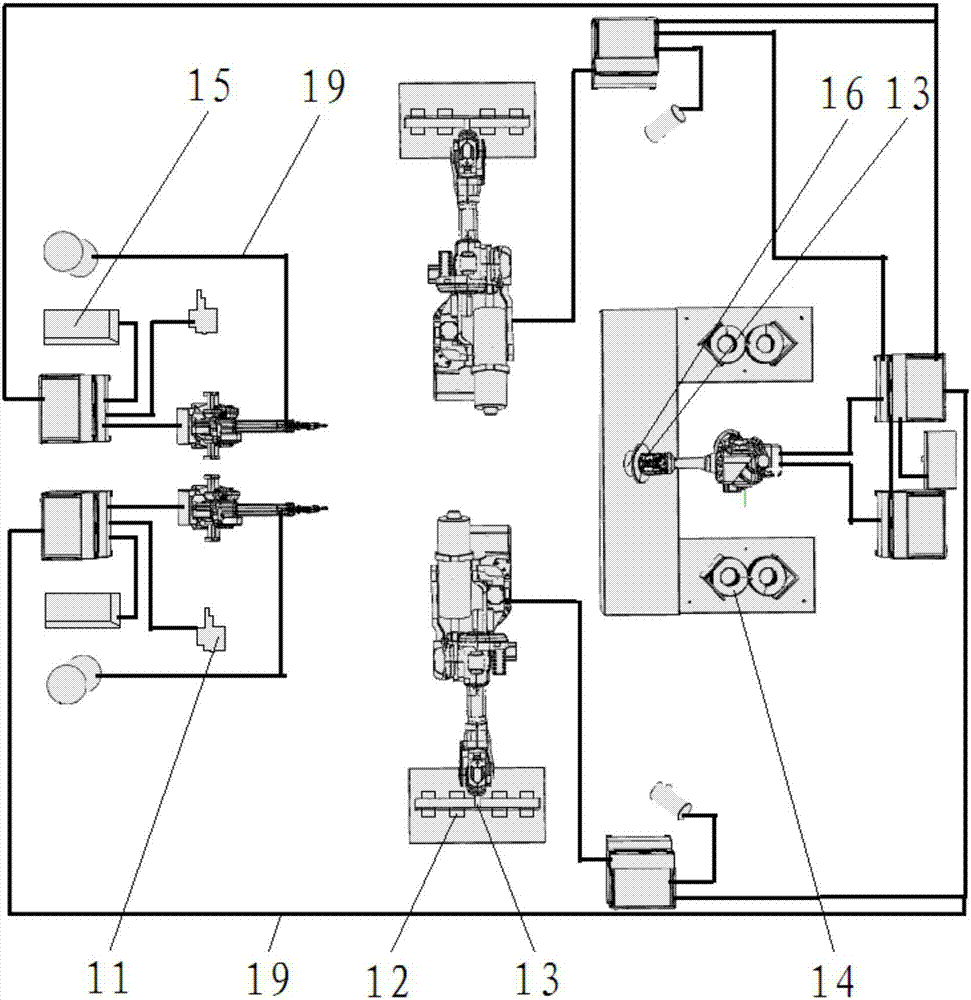

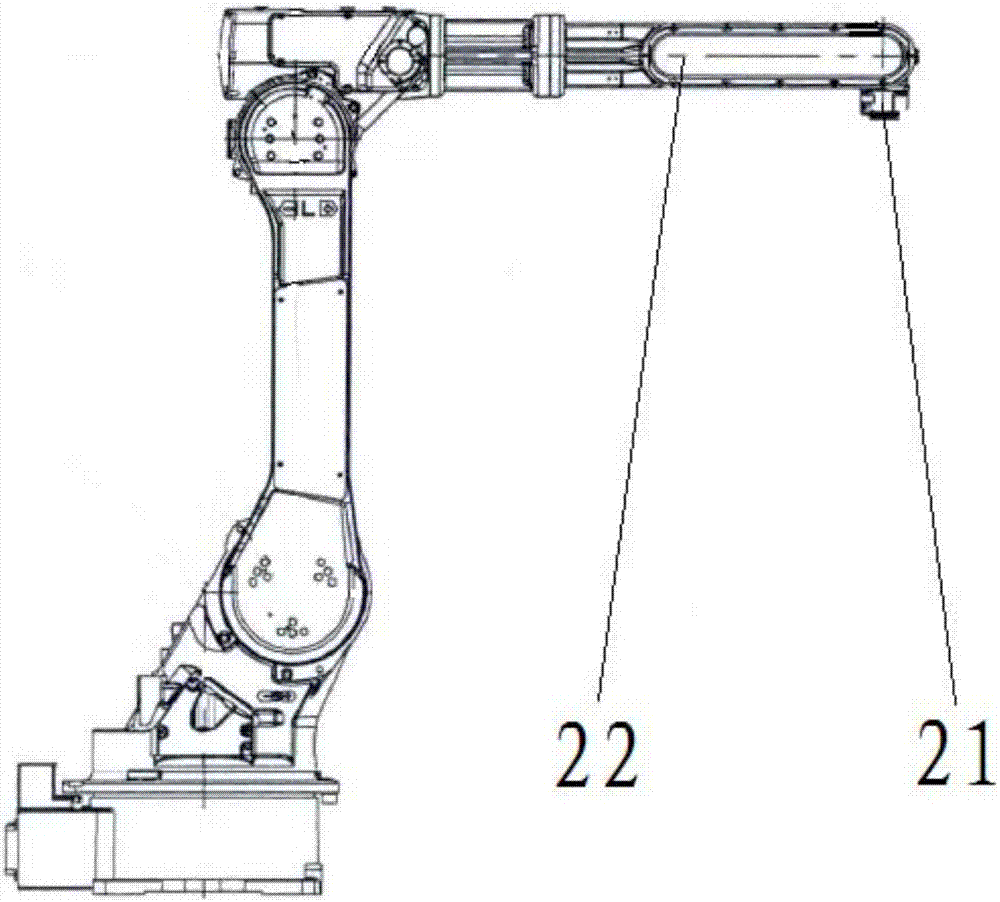

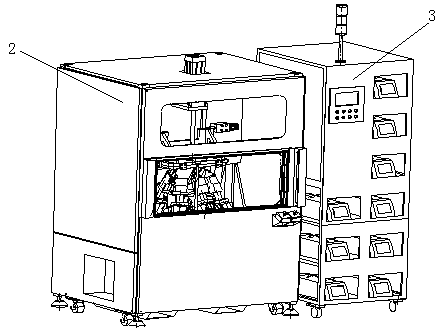

The invention discloses a multi-station robot intelligent welding system for pipe piling sheets. The multi-station robot intelligent welding system comprises a control system, a clamp system, a machine vision system, a robot system, a welding system and a safety protection system, wherein the control system comprises a robot control cabinet, a PLC control cabinet, a machine vision system and a man-machine interface; the robot system comprises two supplying robots, two welding robots and a feeding robot; the two supplying robots are placed in a back-to-back manner; the two welding robots are placed at front middle positions of the two supplying robots side by side; the PLC control cabinet is in communication with the robot control cabinet; the robot control cabinet controls movement of a robot body; the welding system is connected with a welding robot control cabinet; and a welding robot body controls a welding gun to finish welding. By the multi-station robot intelligent welding system, positions and widths of welded joints can be recognized accurately, and information of the welded joints is recognized automatically; and the feeding robot feeds materials automatically, the labor intensity is reduced, and high automation of a whole process of feeding, supplying and welding is realized.

Owner:DALIAN UNIV OF TECH

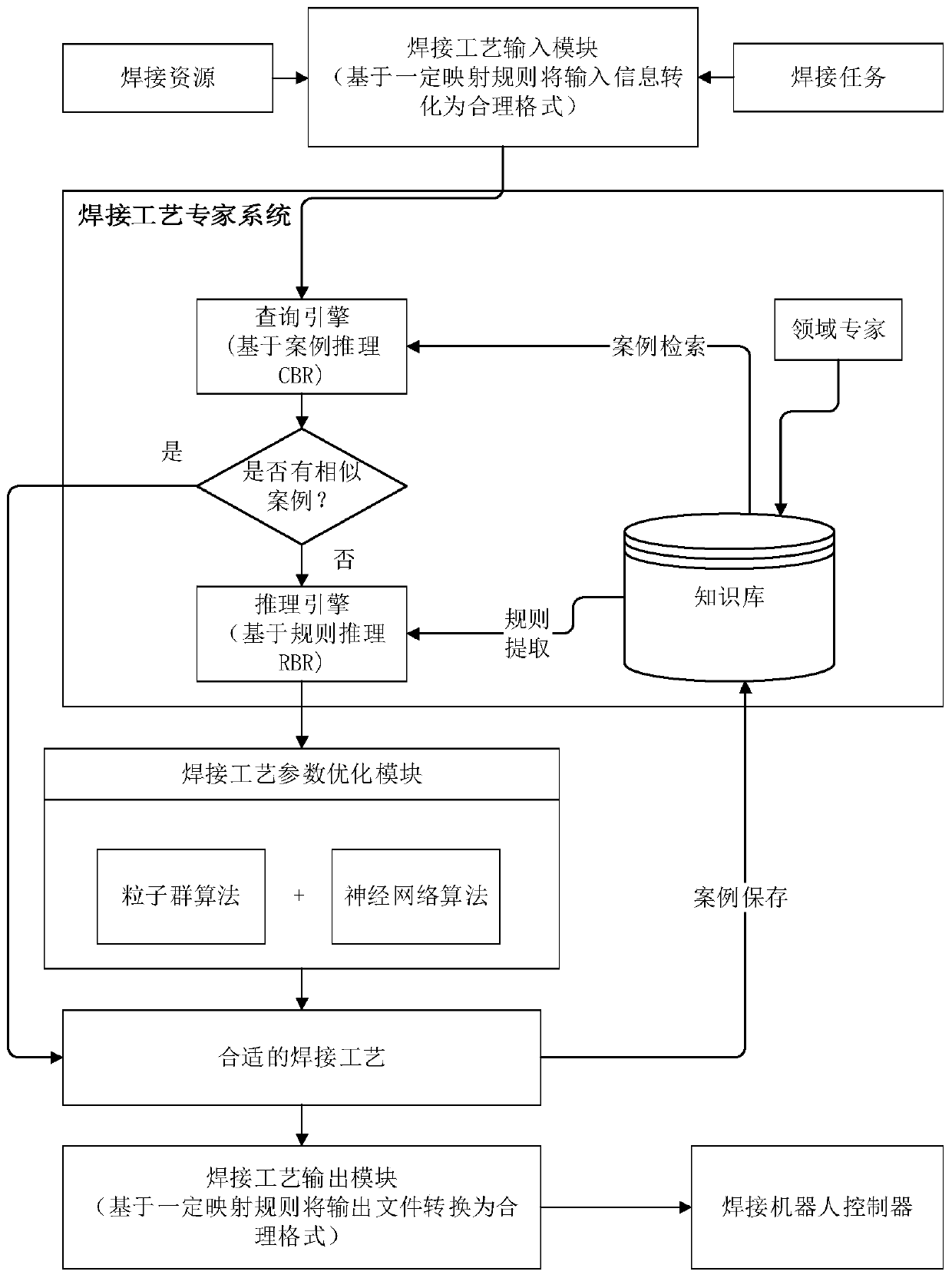

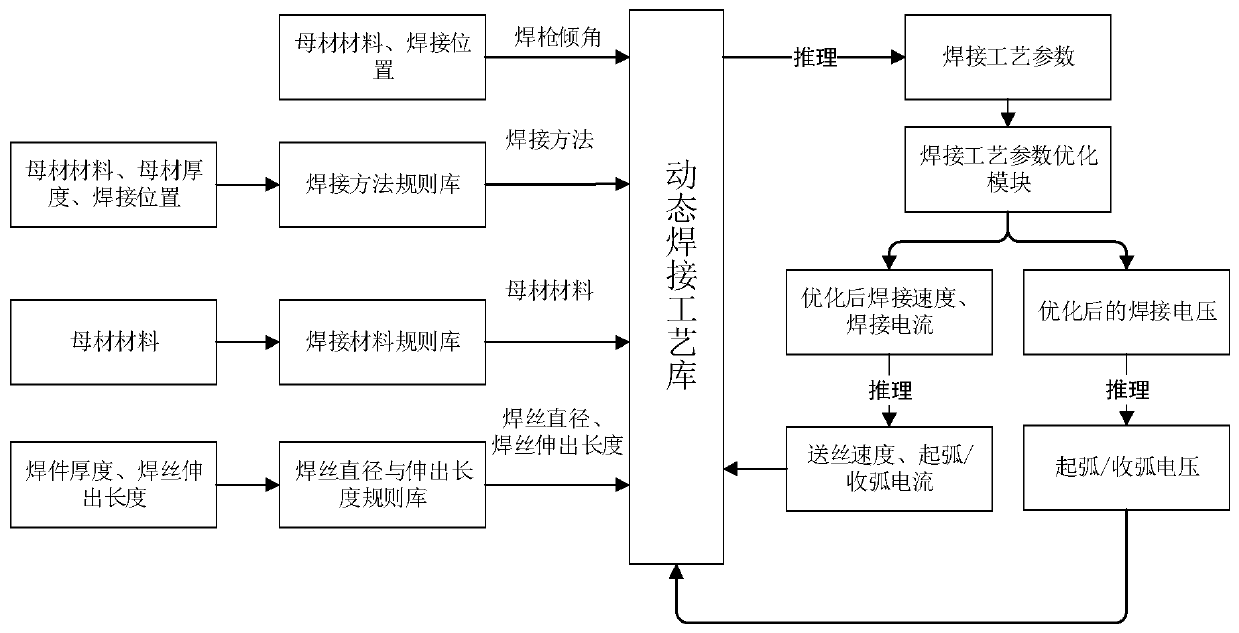

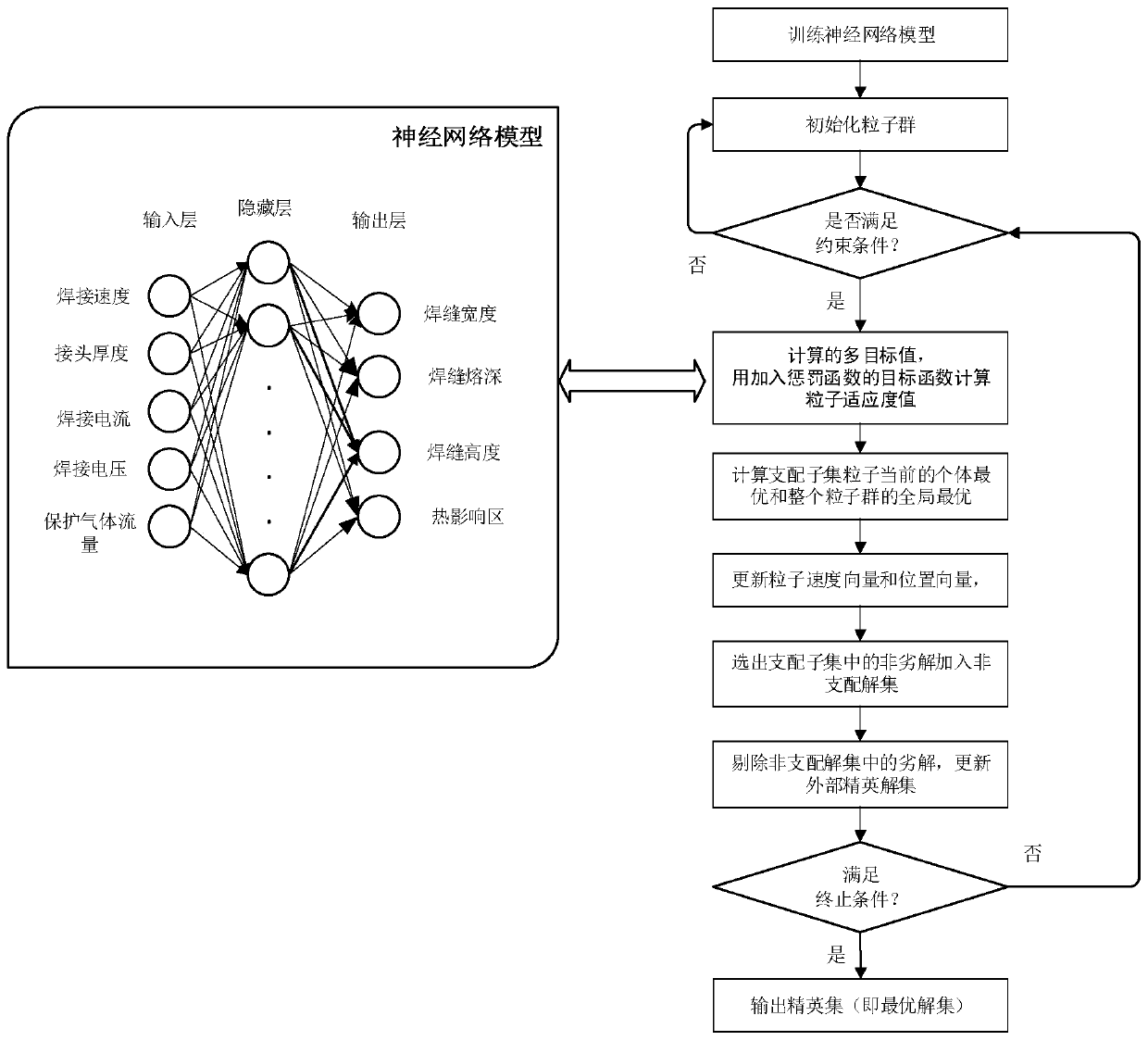

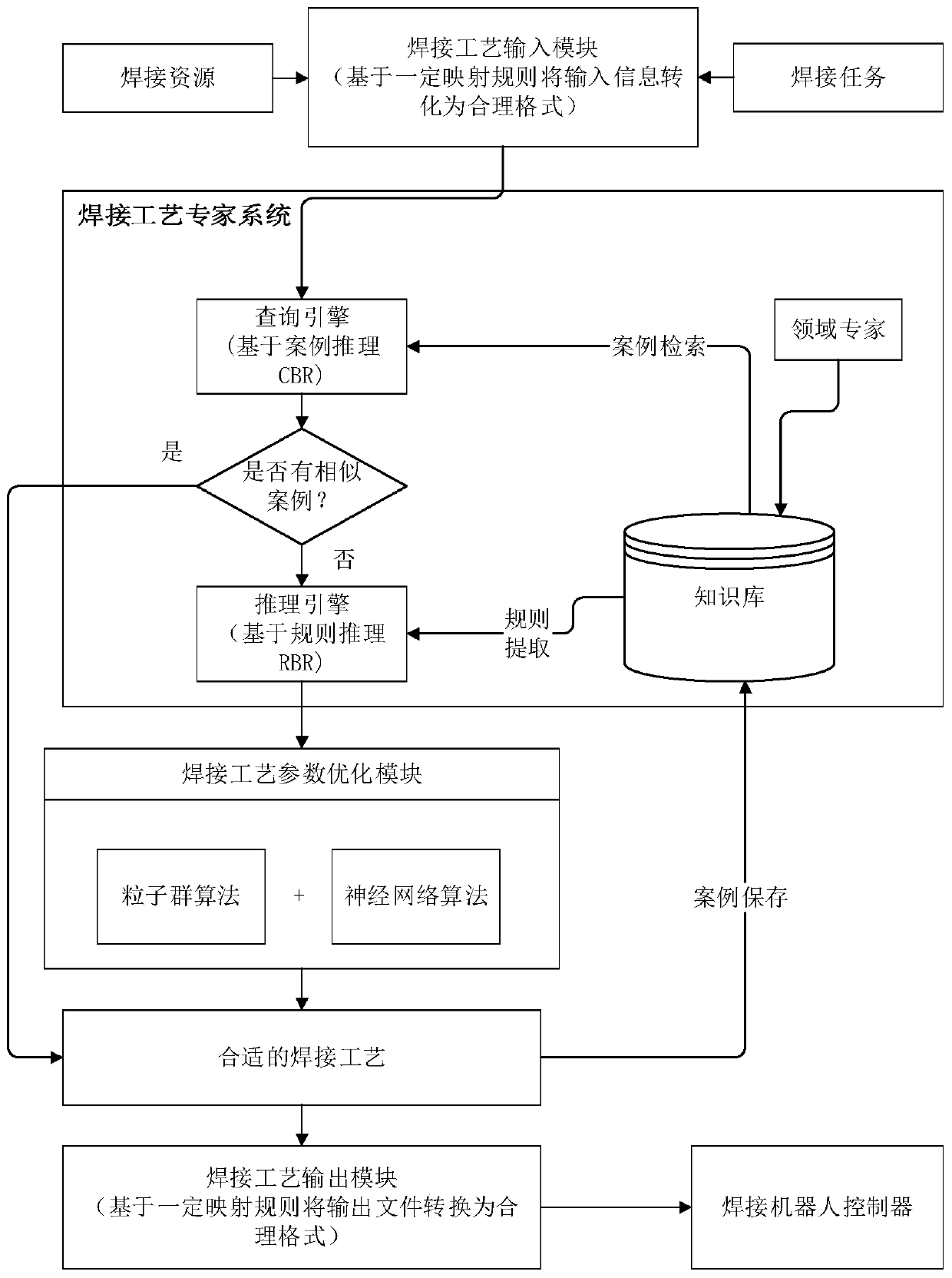

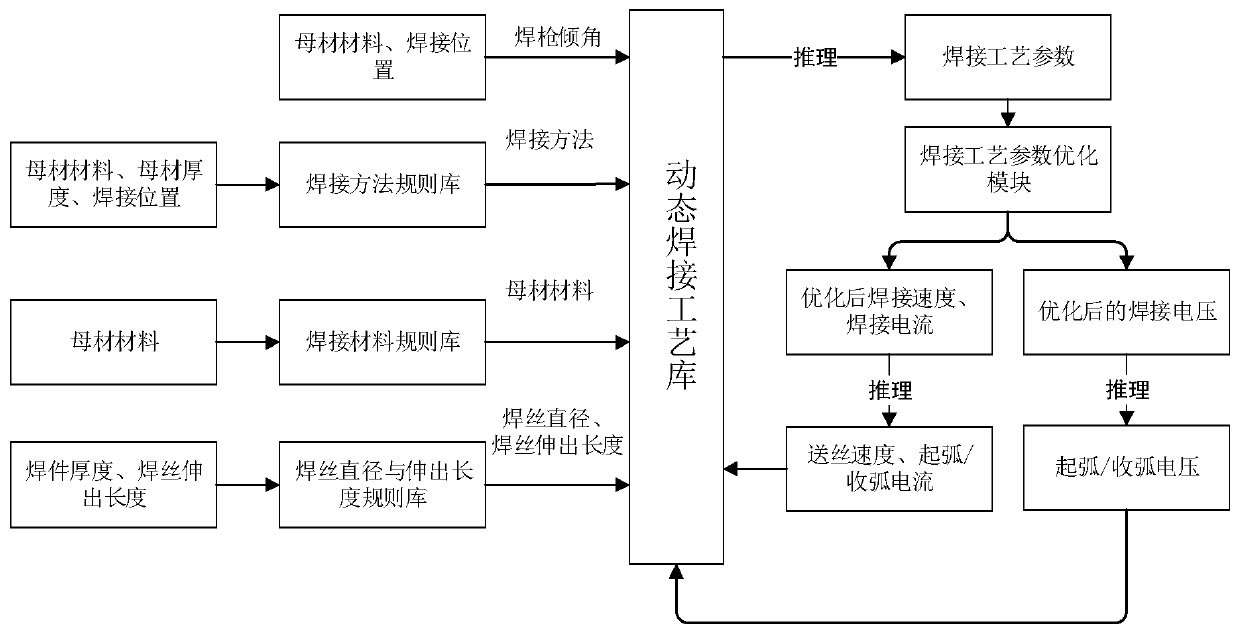

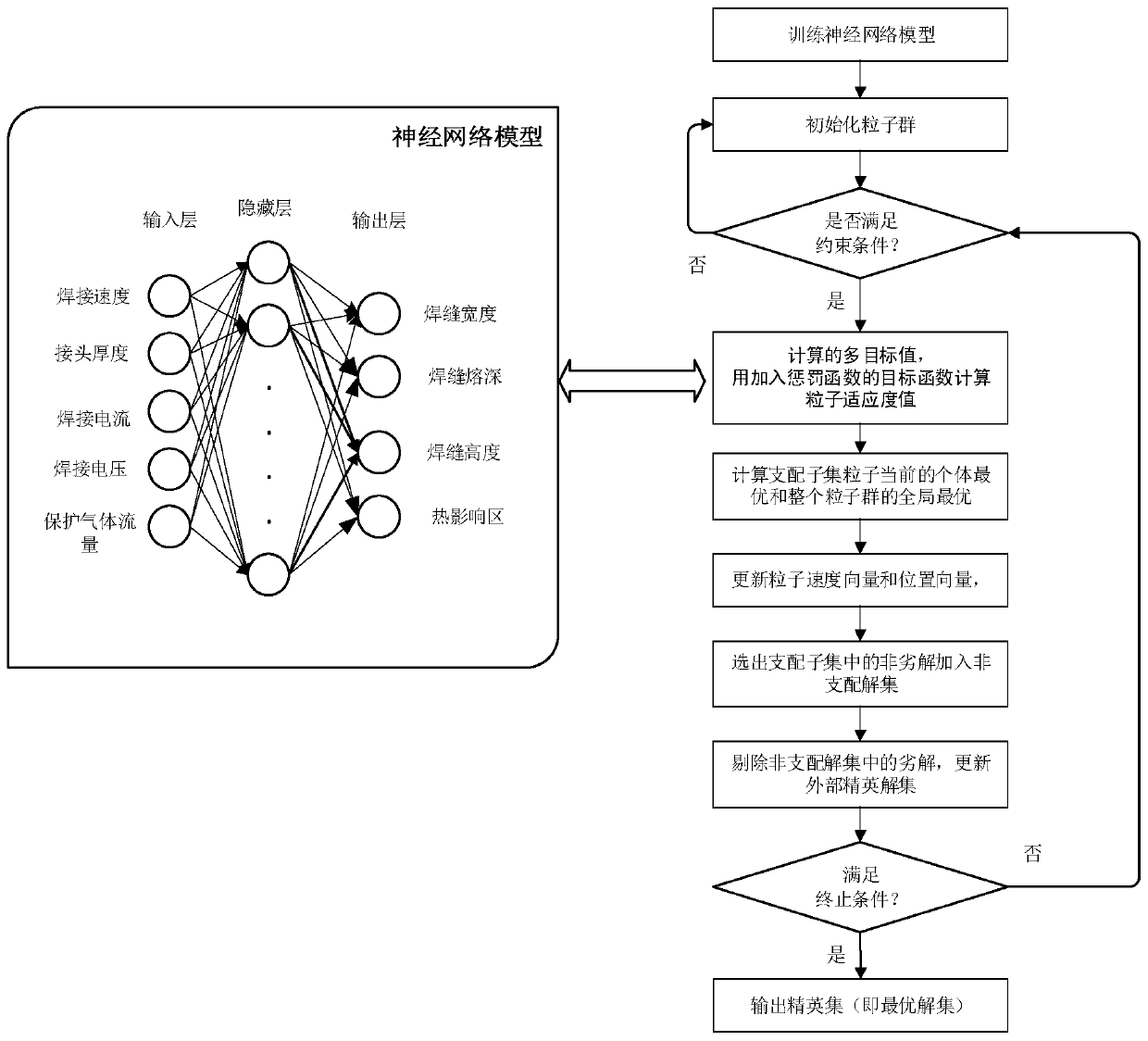

Robot welding technology parameter optimization method based on CBR and RBR

ActiveCN109865916AImprove formulation efficiencyAchieve reuseProgramme-controlled manipulatorWelding accessoriesEngineeringParticle swarm algorithm

The invention relates to a robot welding technology parameter optimization method based on CBR and RBR, and belongs to the technical field of robot welding. The robot welding technology parameter optimization method involves a welding technology input module, a welding technology expert system and a welding technology output module. The welding technology input module receives welding tasks and welding resources and further submits the welding tasks and the welding resources to the welding technology expert system. A query engine in the welding technology expert system reuses historical welding cases, and it enters a reasoning engine for case-based reasoning on the basis of rules if no similar welding technology cases exist. A range value exists in the reasoned welding technology, particleswarm optimization in a welding technology parameter optimization module is adopted for multi-objective optimization of welding technology parameters, the optimal welding technology parameter combination is determined, an exact value is acquired for a welding robot to execute, and robot welding intelligence is realized. Production efficiency can be improved and the effect is remarkable.

Owner:SHANDONG UNIV

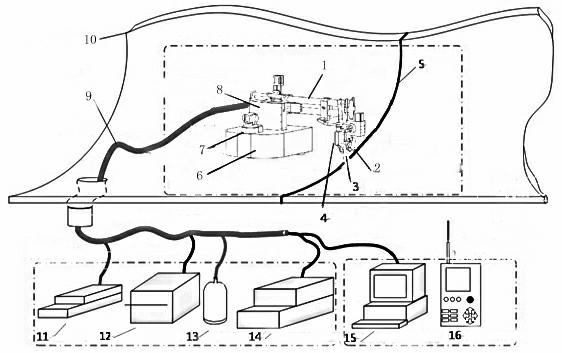

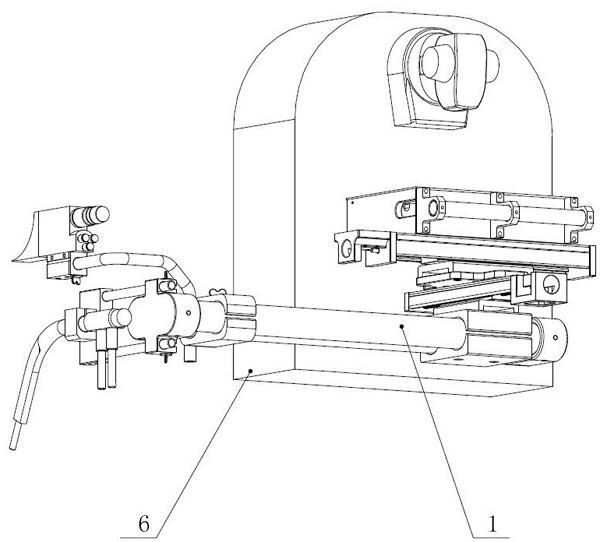

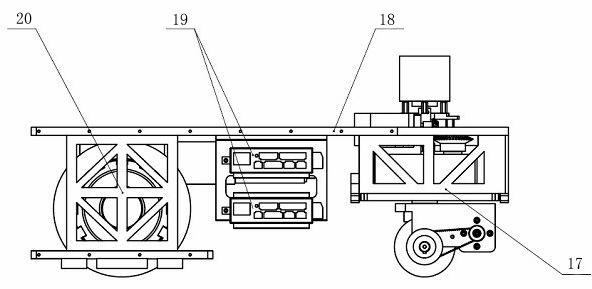

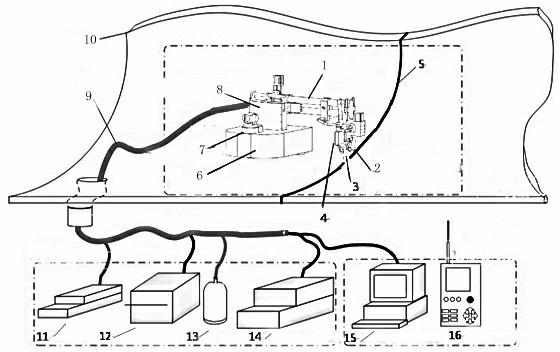

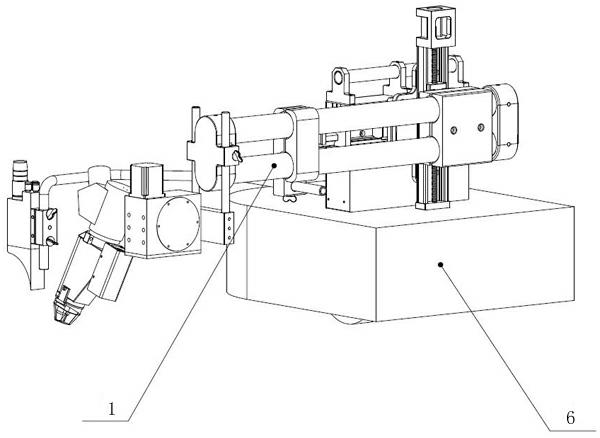

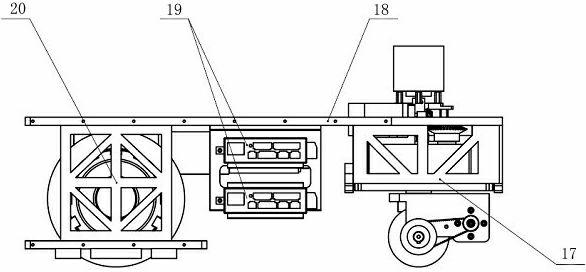

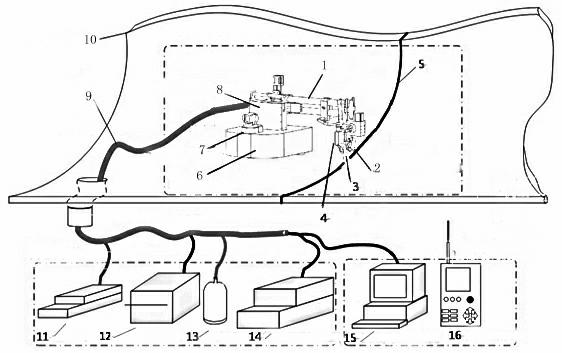

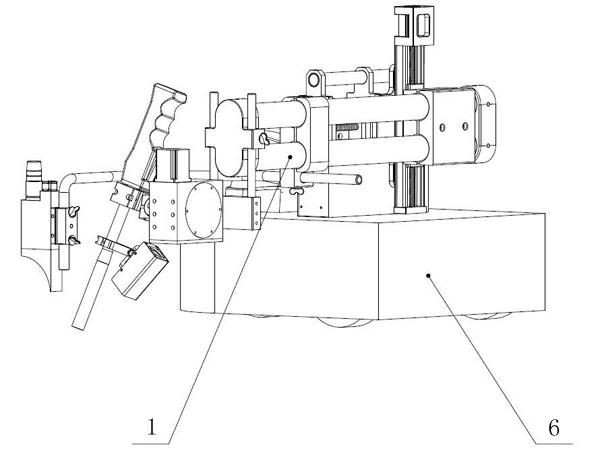

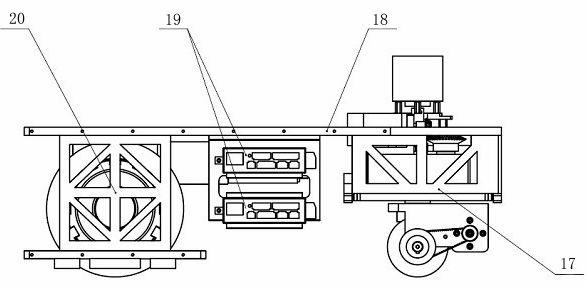

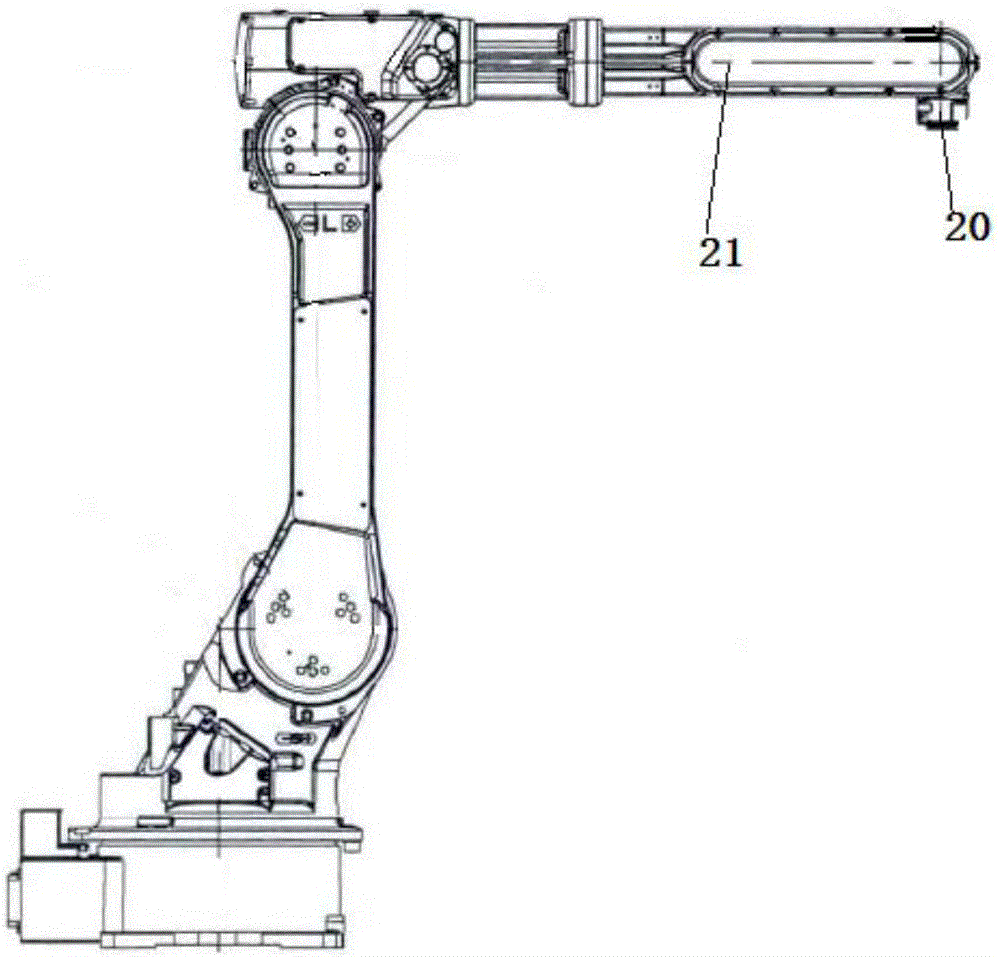

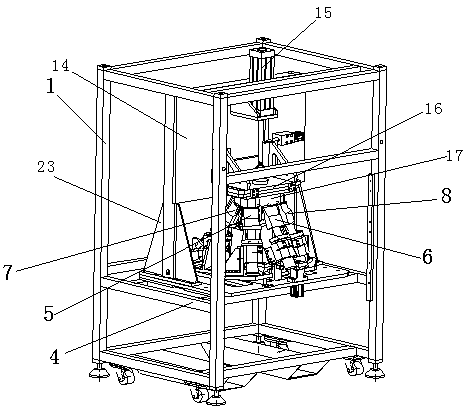

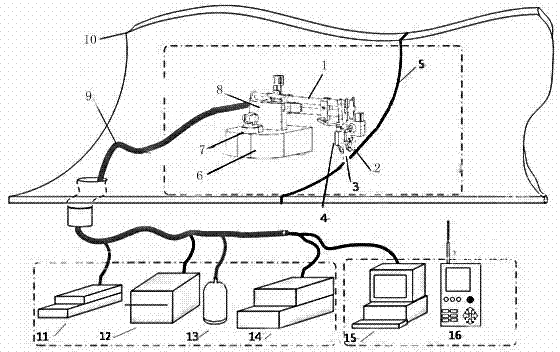

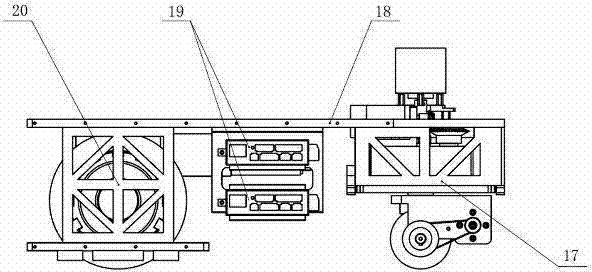

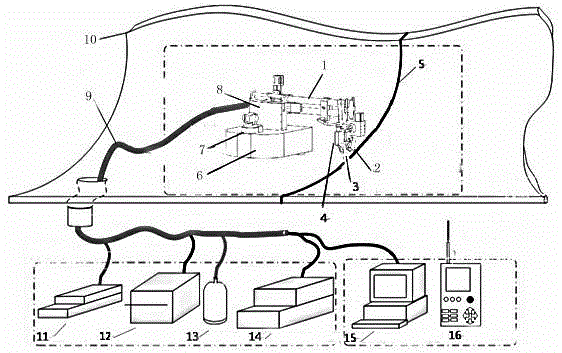

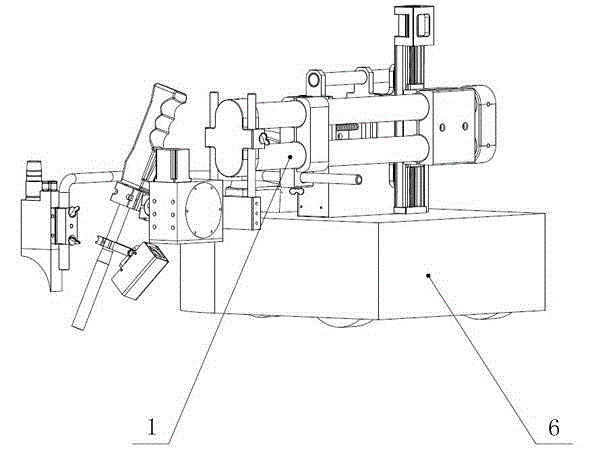

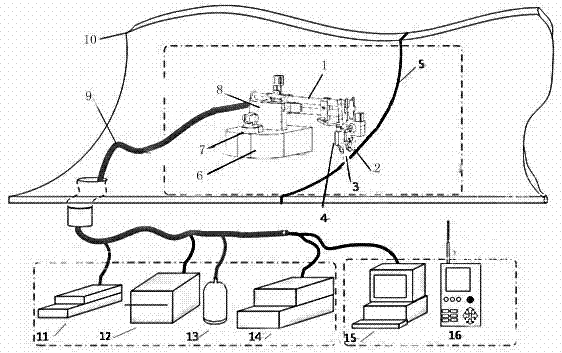

Electro-gas vertical welding automatic moving type robot system

ActiveCN102672311AGood overall system performanceImprove performanceElectrode supporting devicesManipulatorRobotic systemsControl mode

The invention belongs to the technical field of robots and particularly relates to an electro-gas vertical welding automatic moving type robot system which is used for electro-gas vertical welding of large steel structures. The electro-gas vertical welding automatic moving type robot system comprises a robot body, a control system and an electro-gas vertical welding system. The robot body comprises a crawling mechanism and an operation mechanism, the control system comprises a sensing system, a robot body control box and a robot master control system, and the electro-gas vertical welding system comprises an electro-gas vertical welding gun, a welding power source, a wire feeding machine, shielding gas and a welding cooling system. The electro-gas vertical welding automatic moving type robot system has the advantages of adopting a control mode of 'macroscopic remote control and microscopic automation', utilizing a laser tracking sensor to automatically identify and track welding joints, and having functions of remotely arranging welding parameters and adjusting the welding parameters online; adopting a cradle head with multiple degrees of freedom to achieve monitoring of workpiece environments and complete macroscopic operation of an initial point before welding; and having the function of macroscopic and microscopic welding monitoring and achieving intelligent welding.

Owner:DONGFANG ELECTRIC CORP LTD

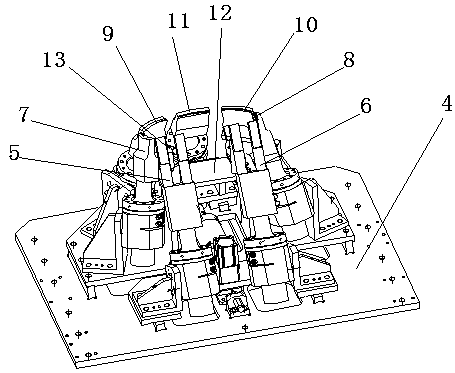

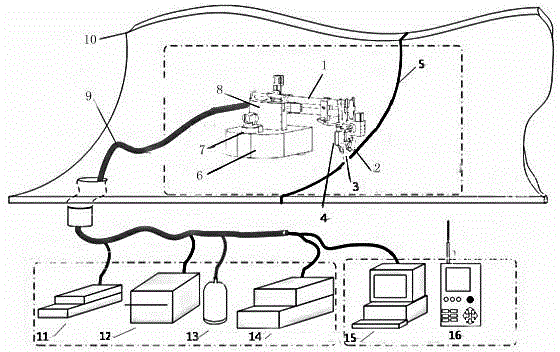

Autonomous mobile robot system for plasma metal-inert-gas (MIG) composite welding

ActiveCN102689100AImprove adsorption capacityImprove performanceWelding/cutting auxillary devicesAuxillary welding devicesMacro environmentWelding power supply

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile robot system for plasma metal-inert-gas (MIG) composite welding. The system comprises a robot body, a control system and a plasma MIG composite welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; and the plasma MIG composite welding system comprises a digitized MIG welding power supply, a plasma power supply, a wire feeding machine, shielding gas, a plasma welding gun and an MIG welding gun. The system has the advantages that a plasma MIG composite welding robot can adapt to an all-position welding mode of a large-sized steel structure; due to the adoption of an adsorption type crawling mechanism, the system can flexibly move; and due to the adoption of a laser welding seam tracking sensor and the arrangement of a macro-environment monitoring and molten pool monitoring system, the system can meet swinging requirements, control requirements and movement requirements in the all-position welding process of large thick plates.

Owner:DONGFANG ELECTRIC CORP LTD

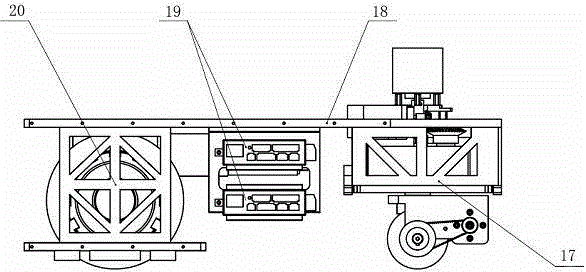

Autonomous mobile robot system for metal-inert-gas (MIG)/metal-active-gas (MAG) multilayer multipass welding of large thick plate

ActiveCN102689083AImprove performanceWith environmental monitoringElectrode supporting devicesDrive wheelShielding gas

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile robot system for metal-inert-gas (MIG) / metal-active-gas (MAG) multilayer multipass welding of a large thick plate. The system comprises a robot body, a control system and an MIG / MAG welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; the MIG / MAG welding system comprises an MIG / MAG welding gun, an MIG / MAG welding power supply, a wire feeding machine, shielding gas and a weld cooling system; and the robot body, the control system and the MIG / MAG welding system are connected with one another through cables. The system has the advantages that a contact type magnet-wheel adsorption and non-contact type clearance adsorption composite mode and a three-wheel full-drive wheel type movement mode are used by the crawling mechanism, so that a robot can autonomously and flexibly move at all positions on the surface of an operating object, can be reliably adsorbed and can perform all-position welding operation, and the system is high in comprehensive performance.

Owner:DONGFANG ELECTRIC CORP LTD

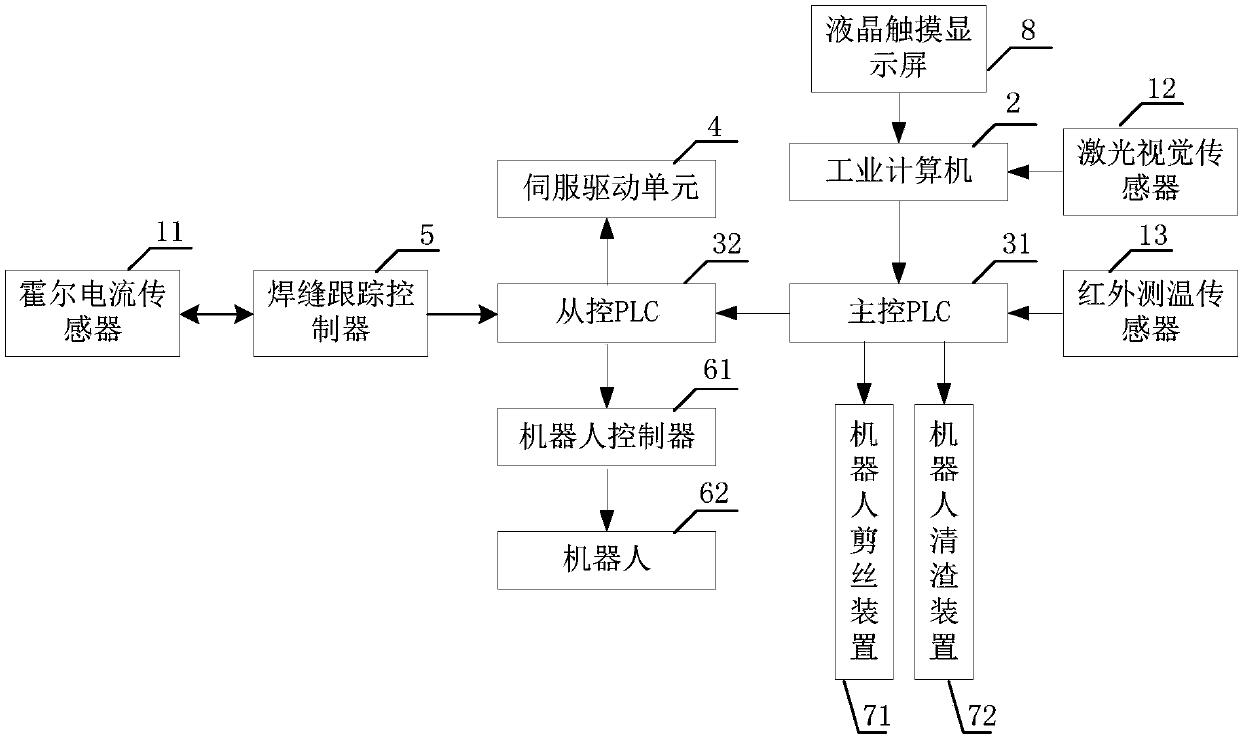

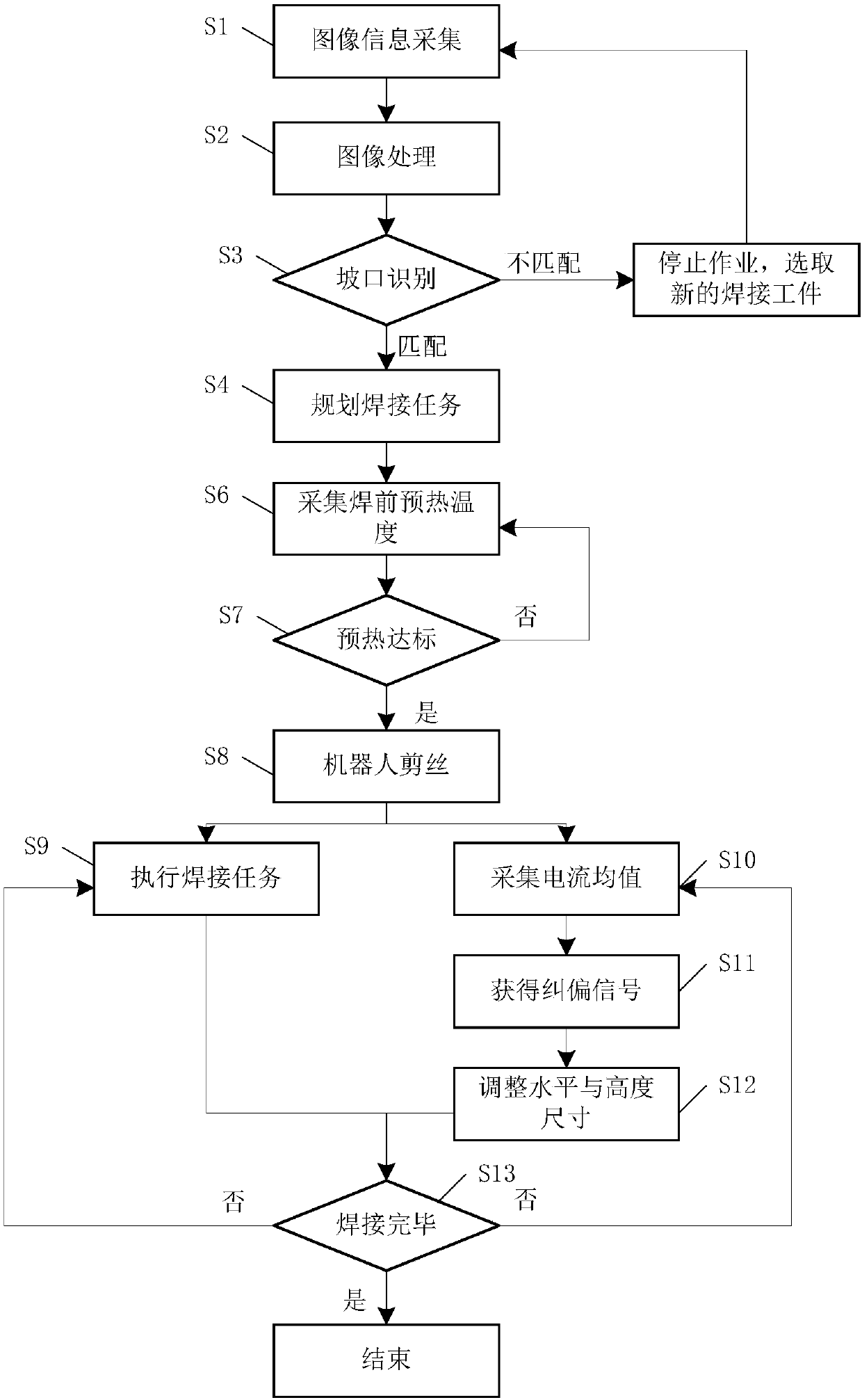

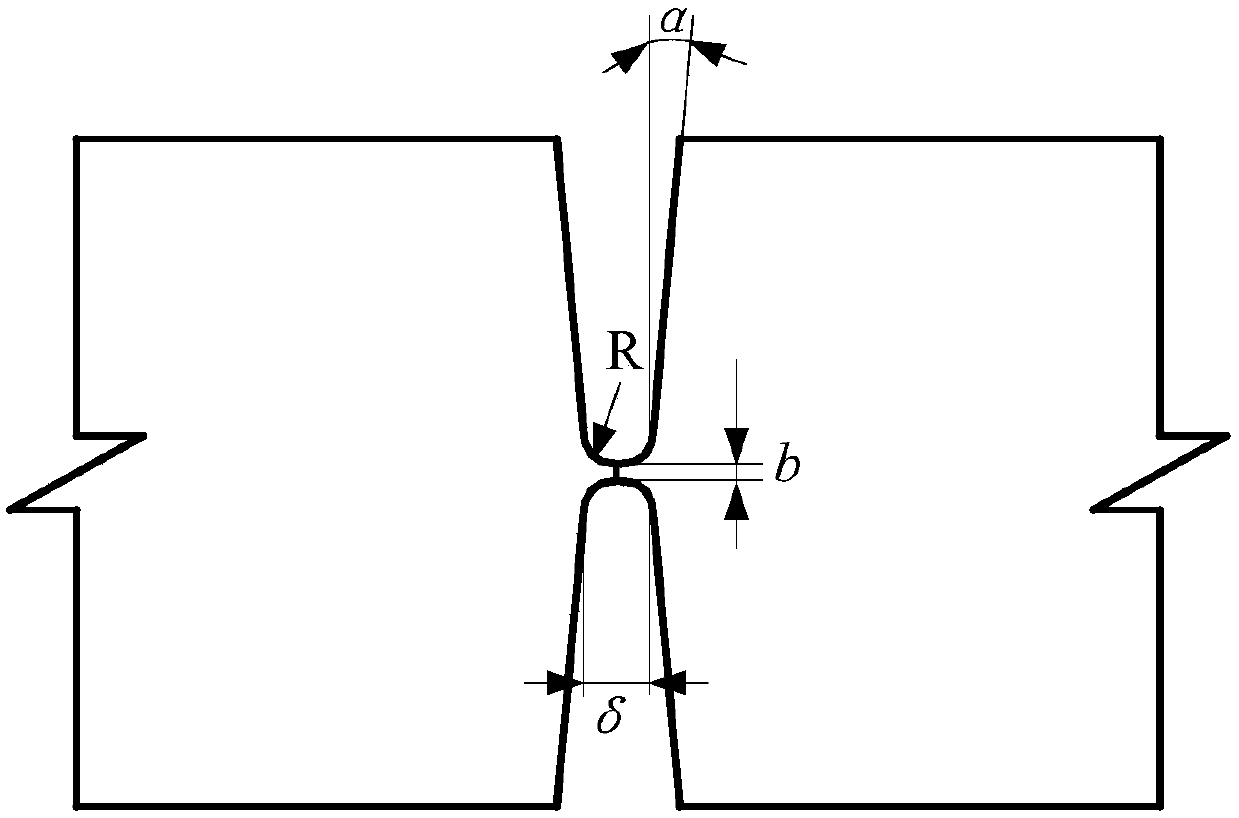

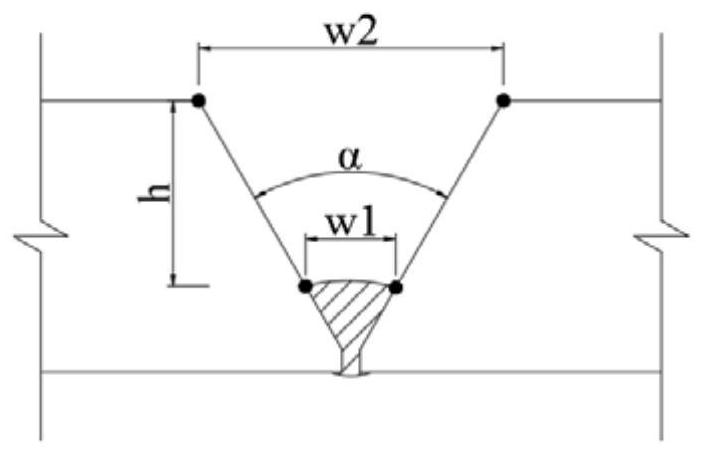

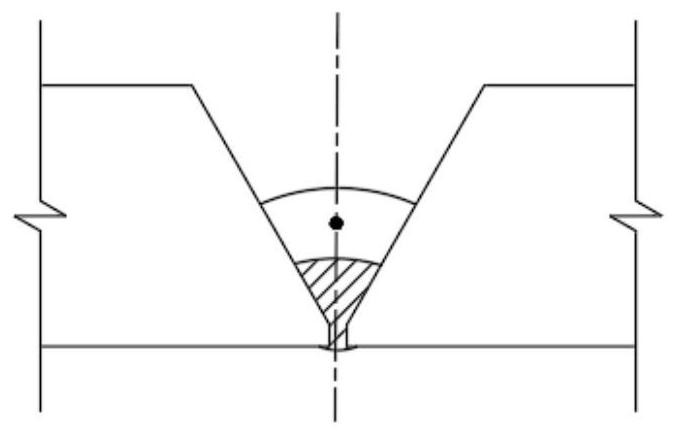

Intelligent welding control system and method for thick-plate narrow-gap GMA robot

The invention discloses an intelligent welding control system and method for a thick-plate narrow-gap GMA robot, and relates to the technical field of welding. The system and method are used for realizing narrow-gap GMA intelligent welding of the thick-plate robot. According to the intelligent welding control system and method for the thick-plate narrow-gap GMA robot, sensing elements of a laser visual sensor, a current sensor, a temperature sensor and the like, and execution mechanisms of a robot, a wire shearing device, a slag removing device and the like are integrated, so that the narrow-gap GMA intelligent welding of the thick-plate robot is realized on the basis of hierarchical control, internet of things and the computer technology.

Owner:ZHEJIANG NORMAL UNIVERSITY

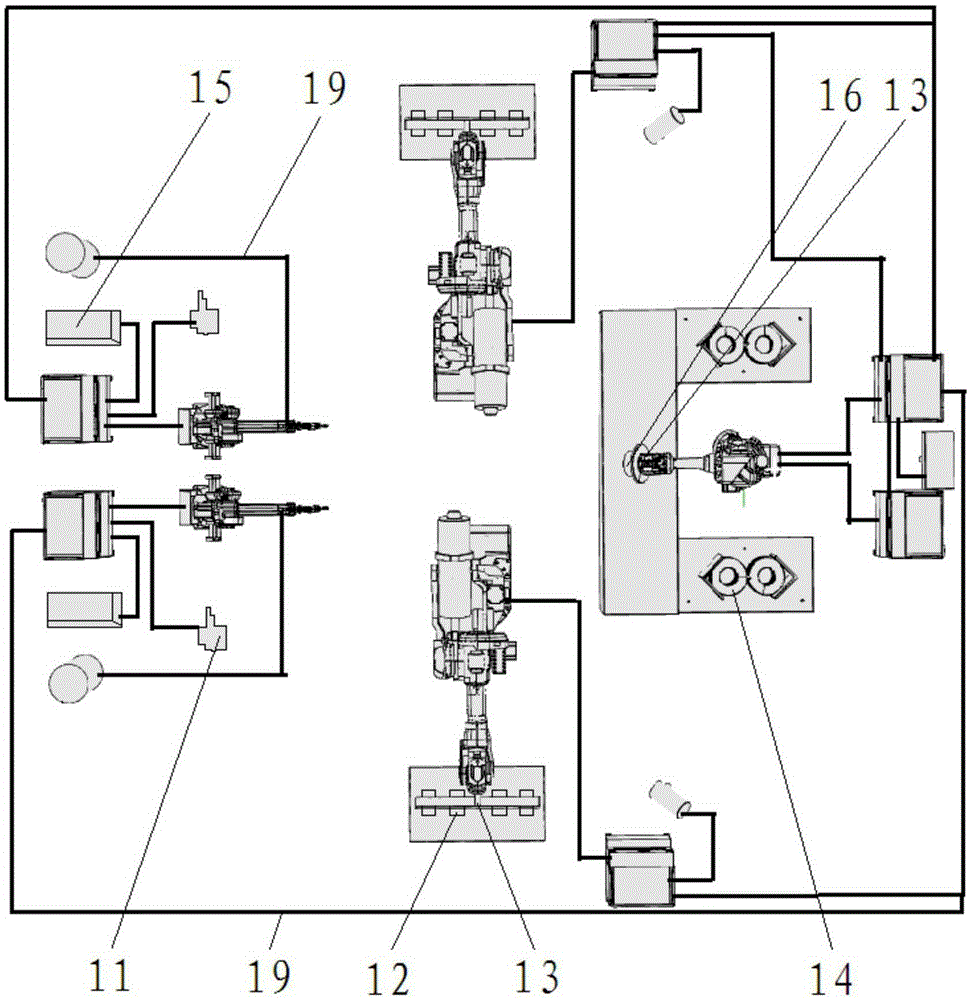

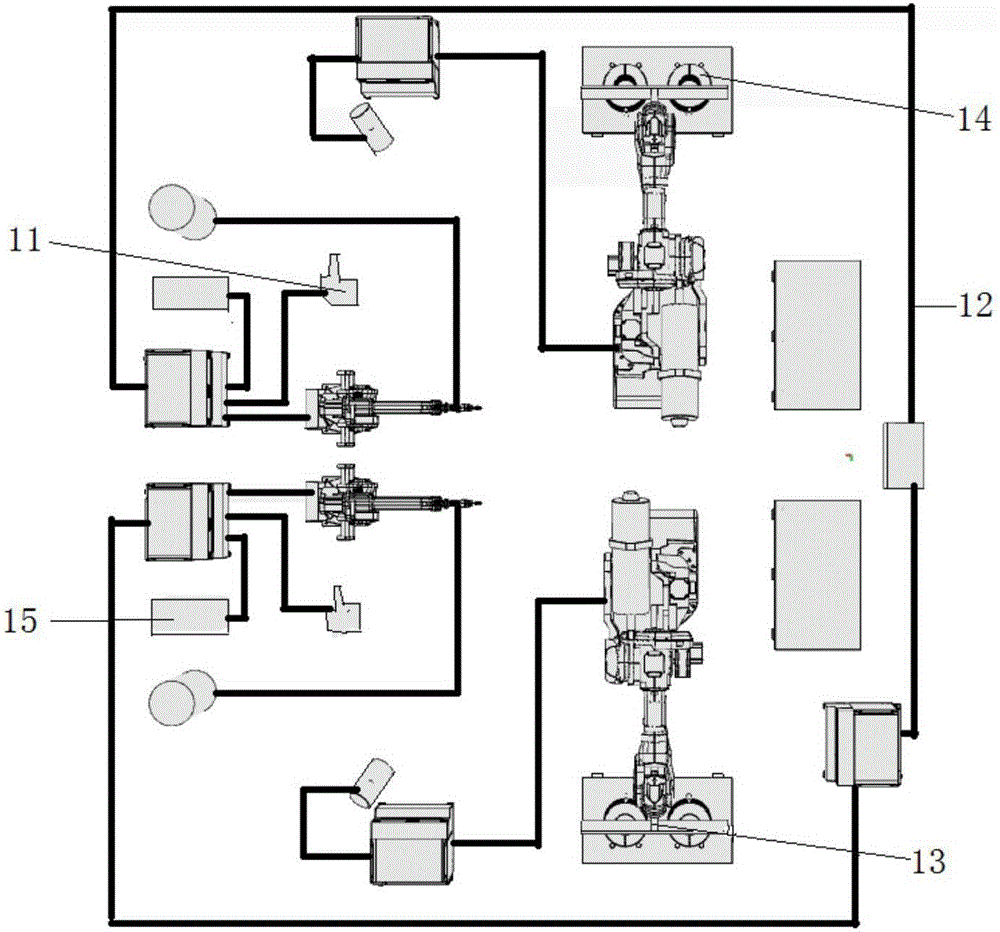

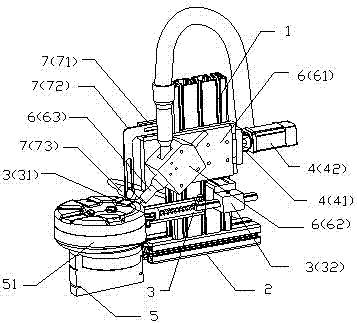

Multi-station robot welding system based on welding seam intelligent identification technology for ring-disc parts

InactiveCN105945441AAccurate identificationRealize intelligent identificationWelding/soldering/cutting articlesMetal working apparatusWeld seamMaterial supply

The invention belongs to the field of intelligent manufacturing and provides a multi-station robot welding system for intelligently identifying welding seams of ring-disc parts. The multi-station robot welding system comprises a robot system, a control system, a clamp system, a machine version system, a welding system and a safety protection system, wherein two material supply robots in the robot system are arranged at the front sides of two finished product racks back to back; two welding robots are arranged on an anterior position between the two material supply robots side by side; the welding system is connected with a welding robot control cabinet; a welding robot body controls a welding gun to complete welding; a PLC control cabinet in the control system communicates with four robot control cabinets, and the robot control cabinets control the robot body to move; and the machine version system comprises a CCD sensor, an auxiliary light source and an industrial controller. The multi-station robot welding system can be used for intelligent and efficient welding of ring-disc parts, can automatically detect and identify positions and widths of welding seams, is reliable in welding quality, and is high in welding efficiency.

Owner:DALIAN UNIV OF TECH

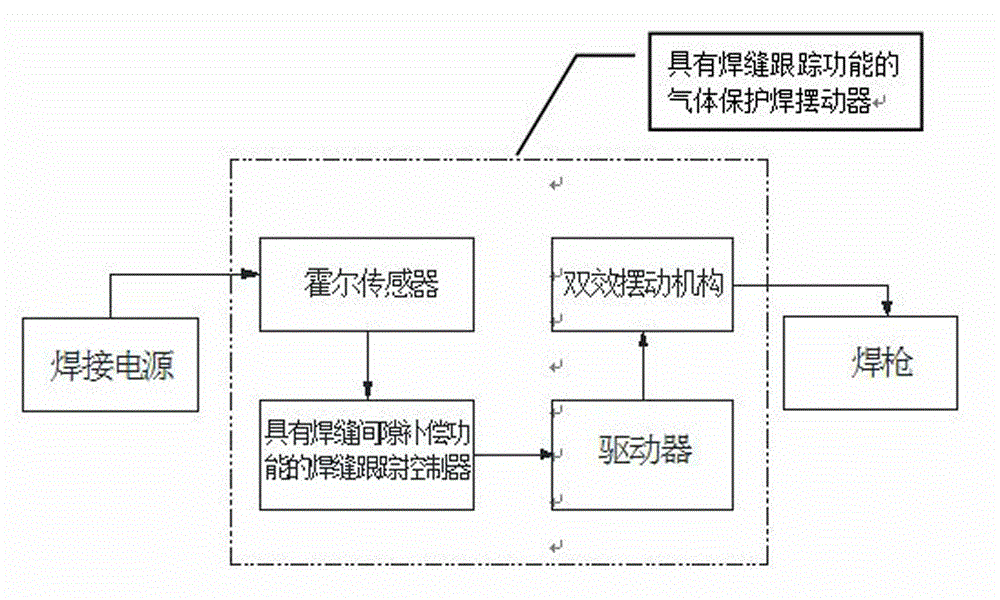

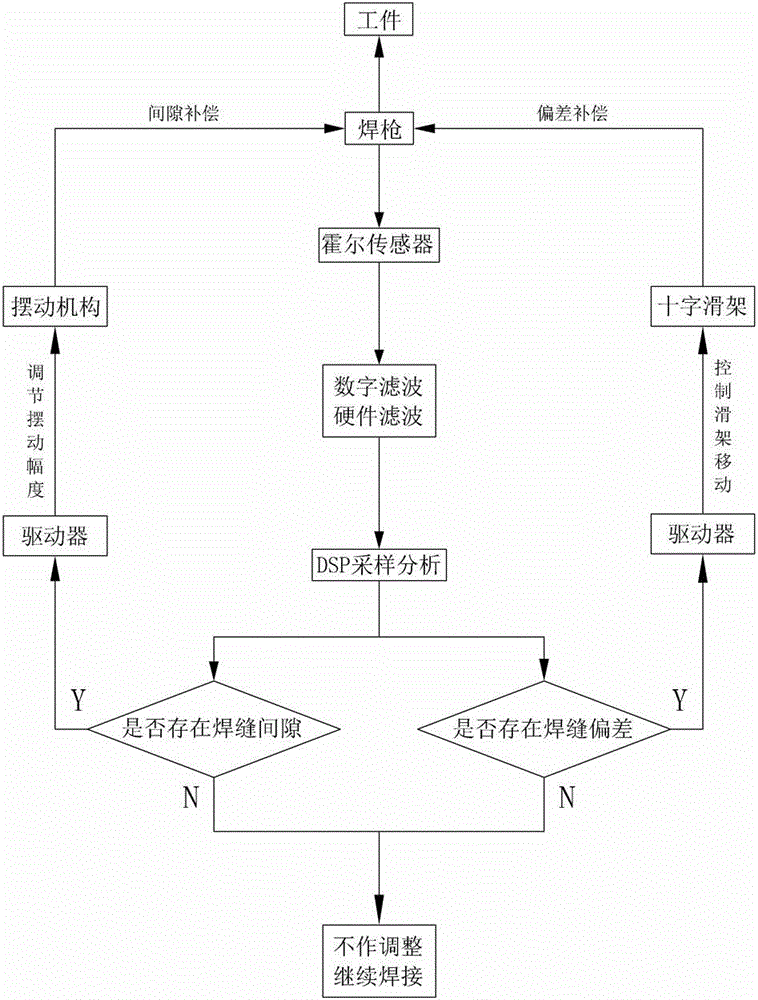

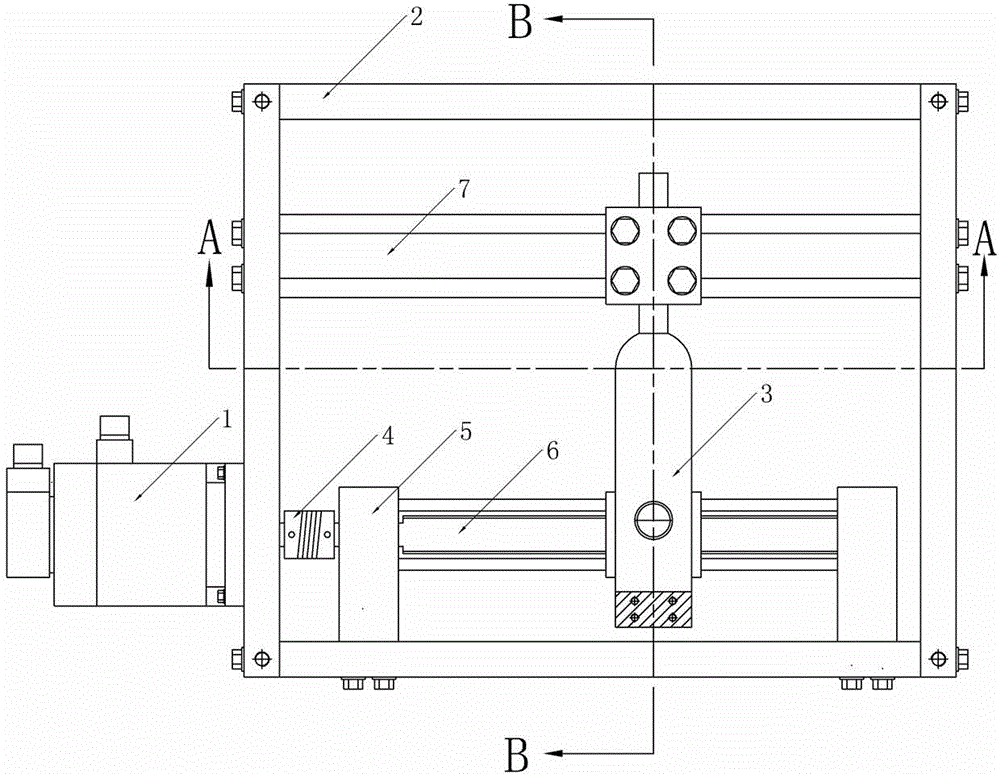

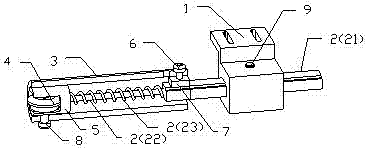

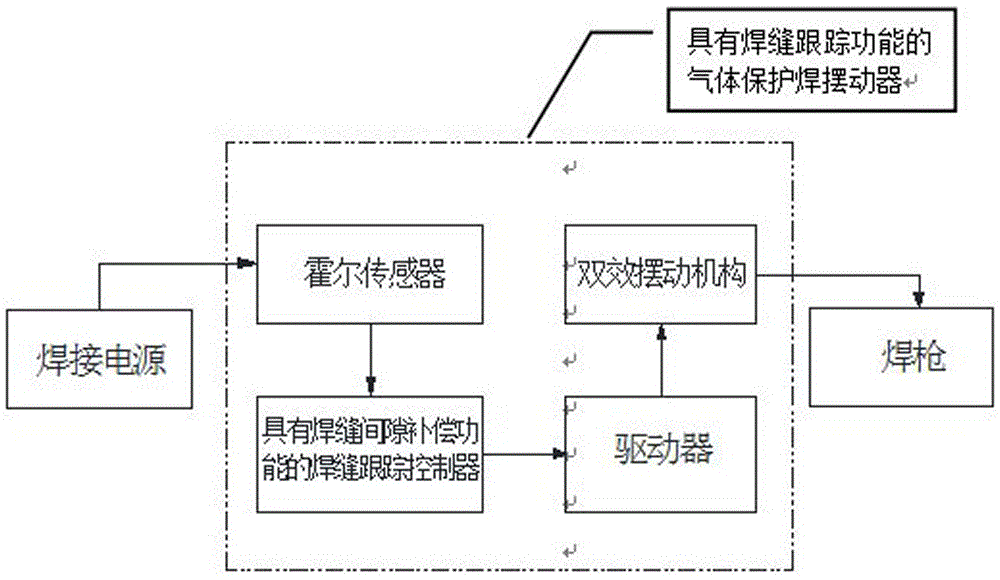

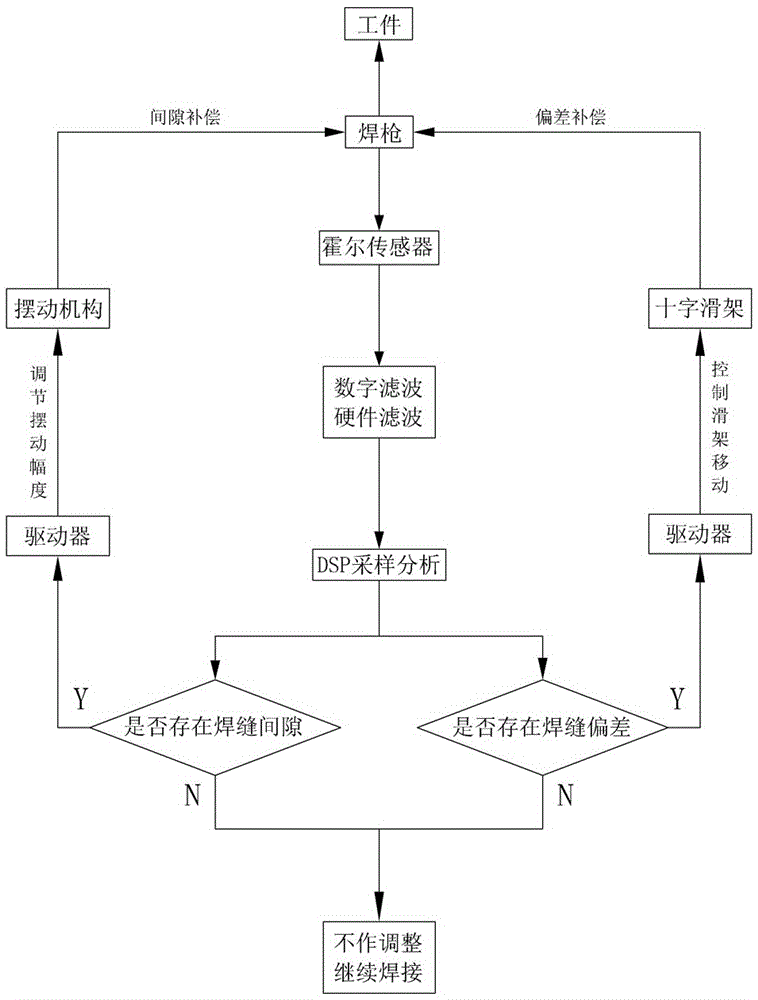

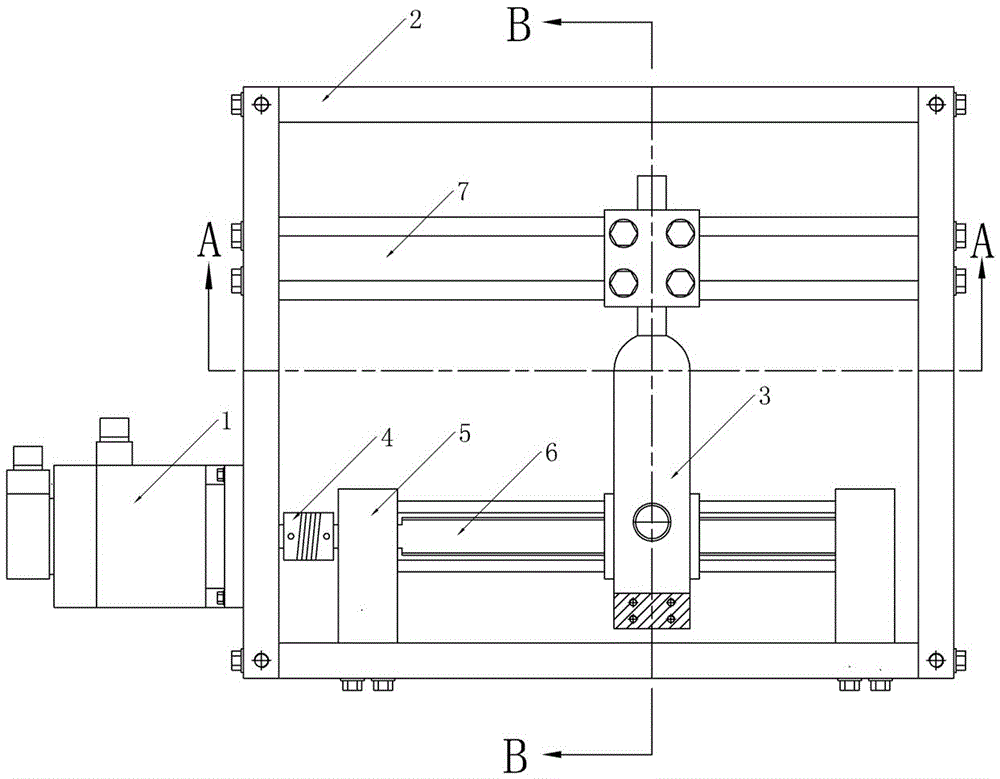

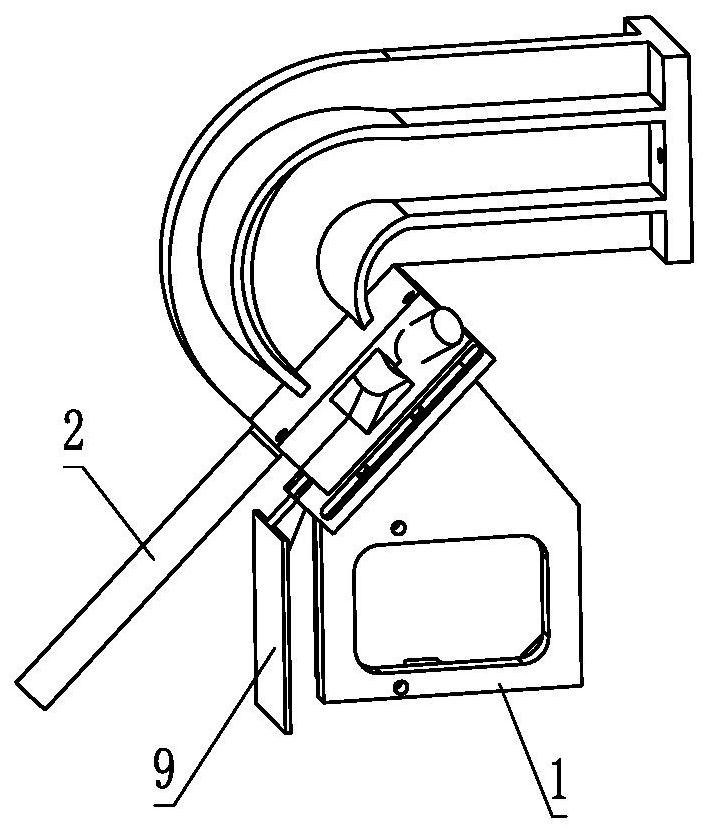

Gas shielded welding oscillator with welding joint tracing function

ActiveCN104475926ALarge coverageRealize real-time compensationElectrode supporting devicesElectrical controlEngineering

The invention discloses a gas shielded welding oscillator with a welding joint tracing function and belongs to a welding automation control device. The gas shielded welding oscillator with the welding joint tracing function mainly solves the technical problems of large welding joint gap and the like due to the fact that an existing oscillator is incapable of detecting and compensating a workpiece processing error, an assembly error, welding heat deformation and the like errors in real time. According to the technical scheme, the gas shielded welding oscillator with the welding joint tracing function comprises a Hall sensor, a welding joint tracing controller with a welding joint gap compensation function, a driver and a double-effect swinging mechanism, the welding joint tracing controller detects and compensates the welding joint gap caused by workpiece processing errors, assembly errors and welding heat deformation in real time according to signals gathered by the Hall sensor, and under the electric control and the driver control, the double-effect swinging mechanism freely changes between horizontal swinging and pendular swinging and automatically regulates the swinging amplitude and swinging frequency. The gas shielded welding oscillator with the welding joint tracing function is mainly used for welding.

Owner:湖南艾克机器人有限公司

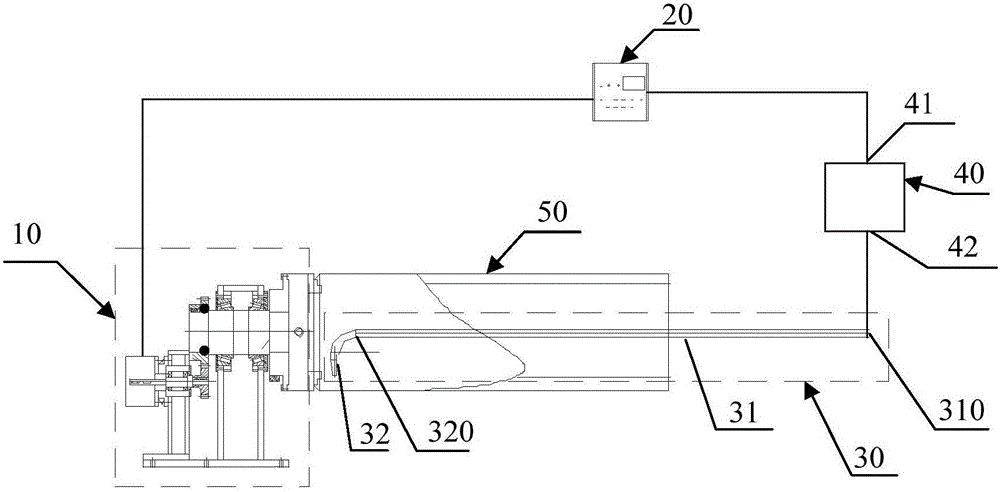

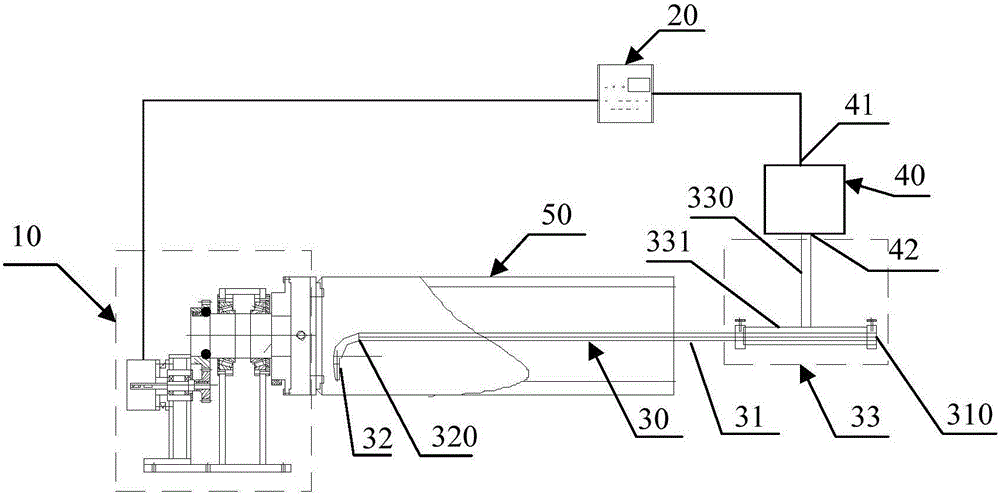

Double-torch pipeline full-position automatic welding machine

InactiveCN102371418ARealize intelligent weldingImprove welding qualityArc welding apparatusPipeline systemsPower flowWelding power supply

The invention discloses a double-torch pipeline full-position automatic welding machine. The double-torch pipeline full-position automatic welding machine comprises a welding tractor which is arranged on a guide rail, a welding control box, a wire feed box, a welding power supply and a manual control box; the welding tractor is provided with a travelling mechanism, two welding torches which are controlled by a swinging mechanism, and a height adjustment mechanism; a controller is arranged in the welding control box; the double-torch pipeline full-position automatic welding machine is characterized in that: the welding tractor is provided with a laser tracking probe and a sensor which are connected with the controller in the welding control box respectively; and the controller is connected with a computer. A welding line is automatically tracked by the laser tracking probe, and a welding process is not needed to be interfered by a welder, so welding automation is realized and labor intensity of the welder is reduced; under the control action of the computer, the welding power supply provides welding current and arc voltage which are matched with the position, and welding forming quality is improved; and a cable number is simplified and maintenance and expansion capacity of a system is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

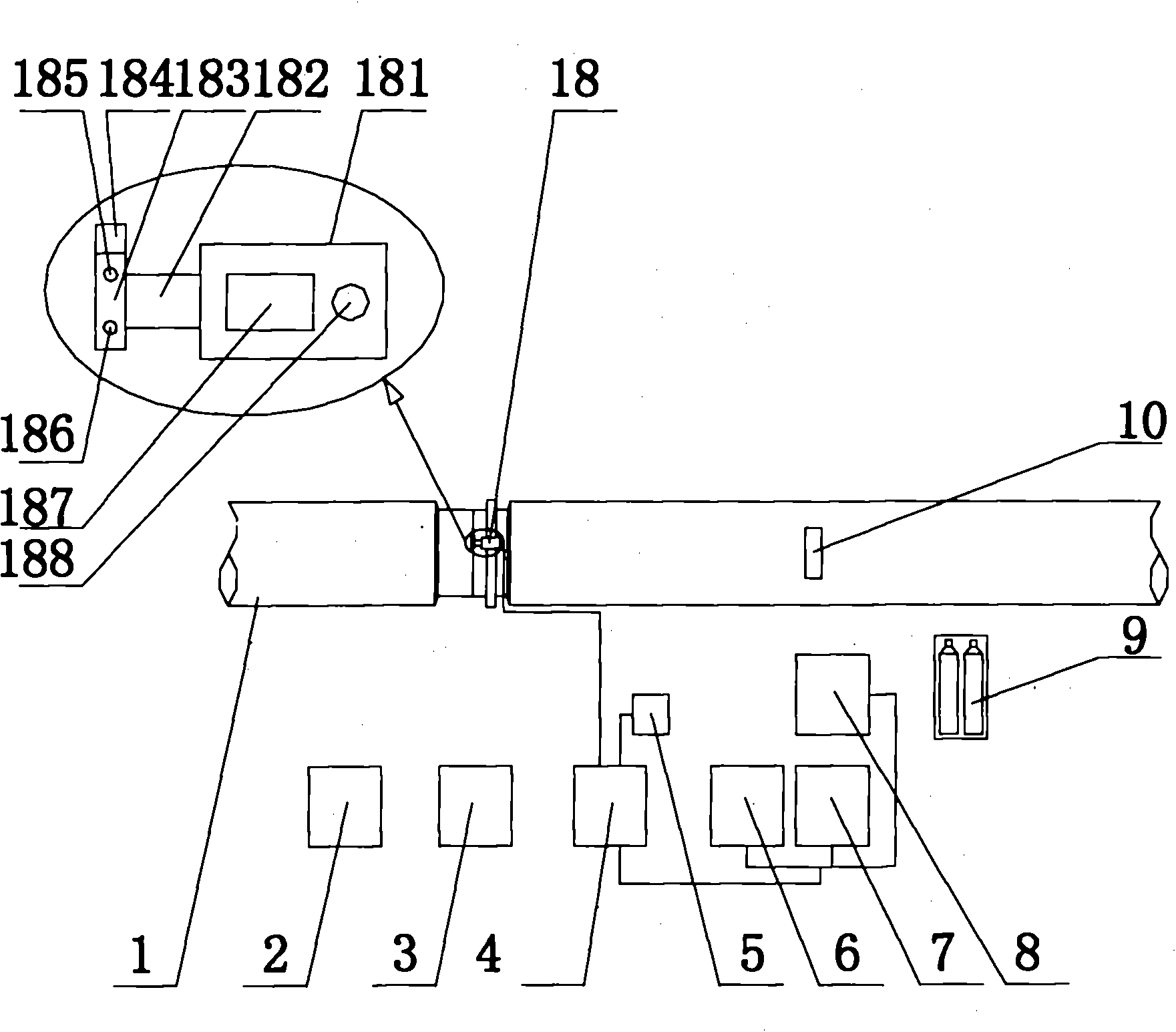

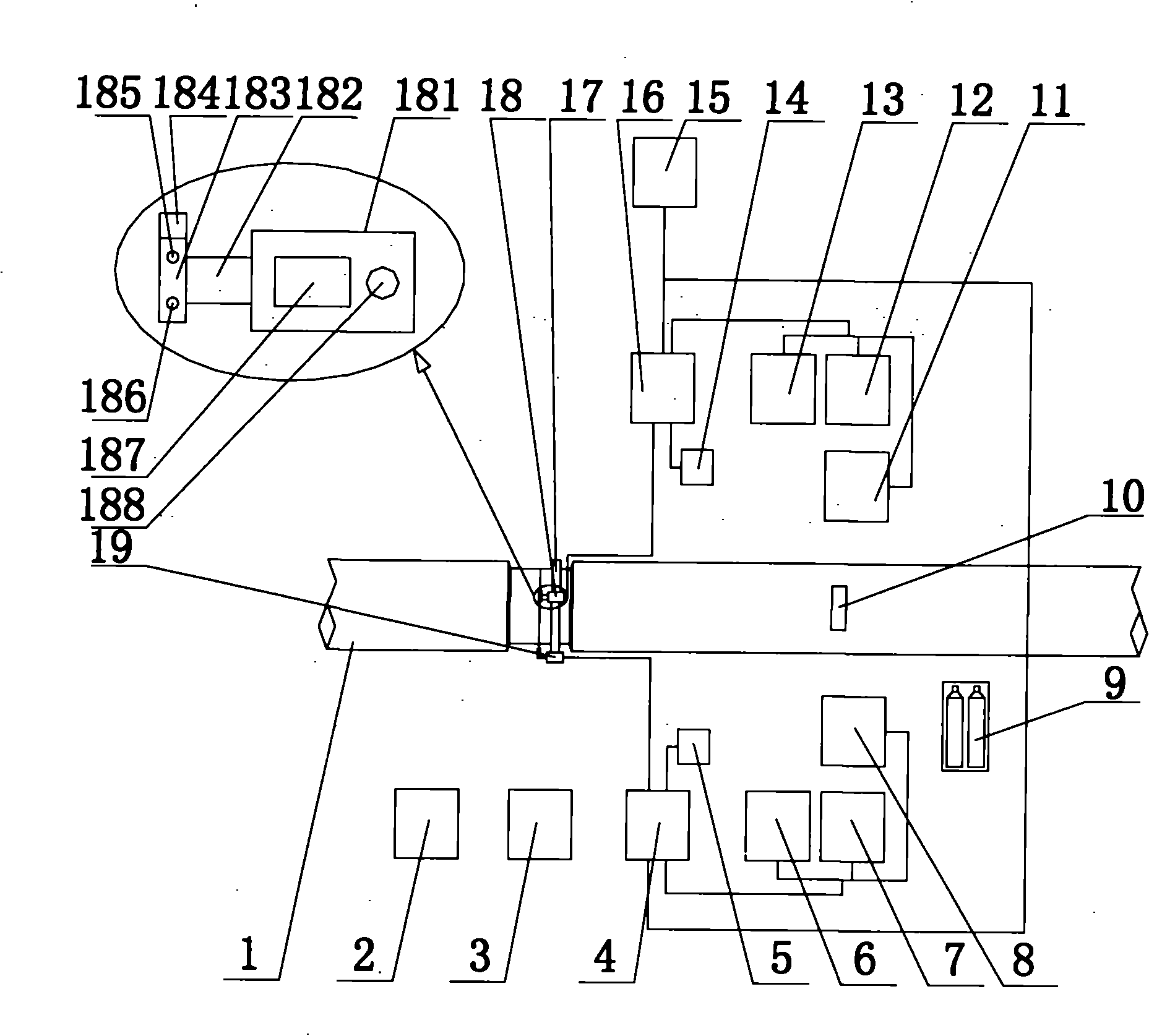

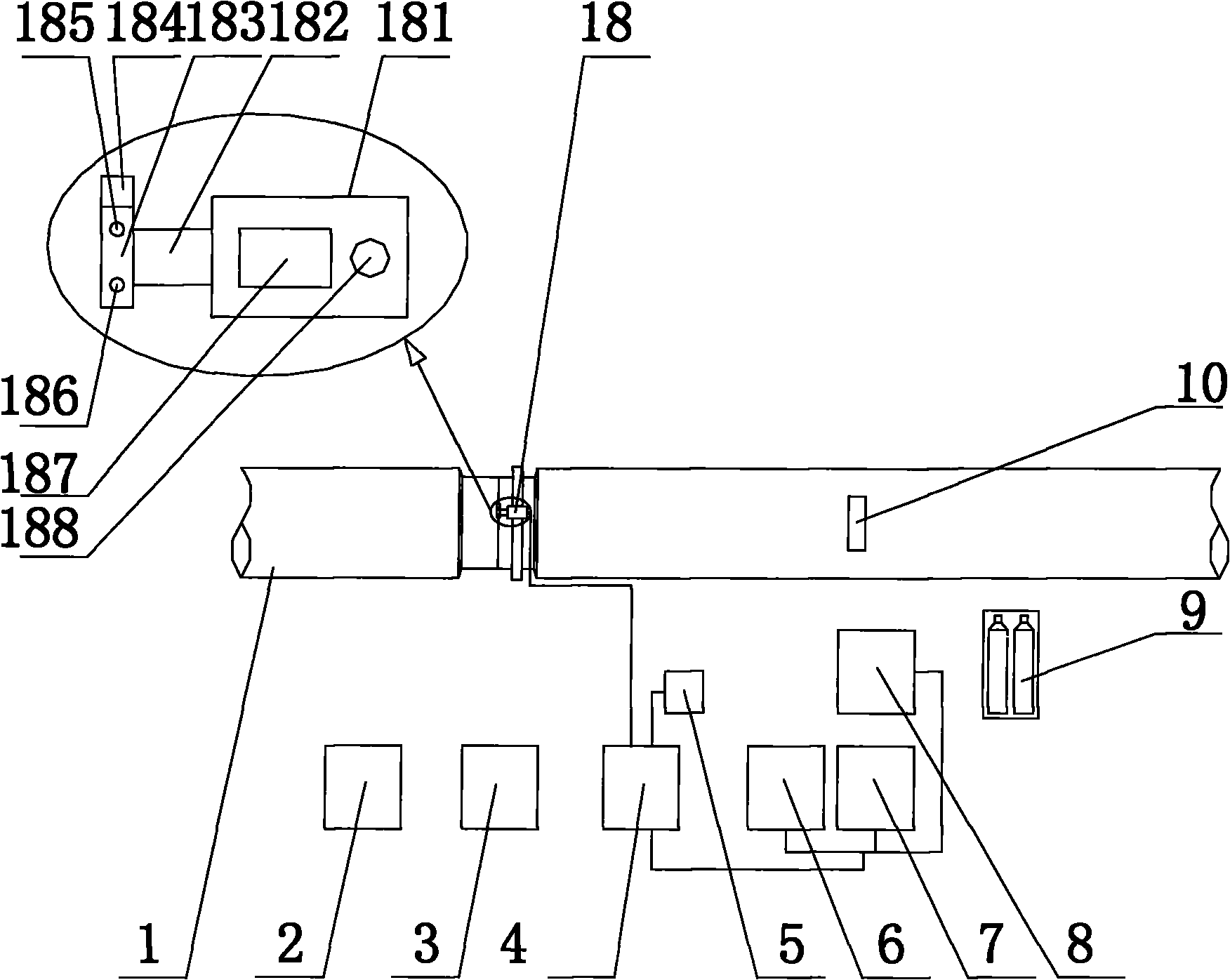

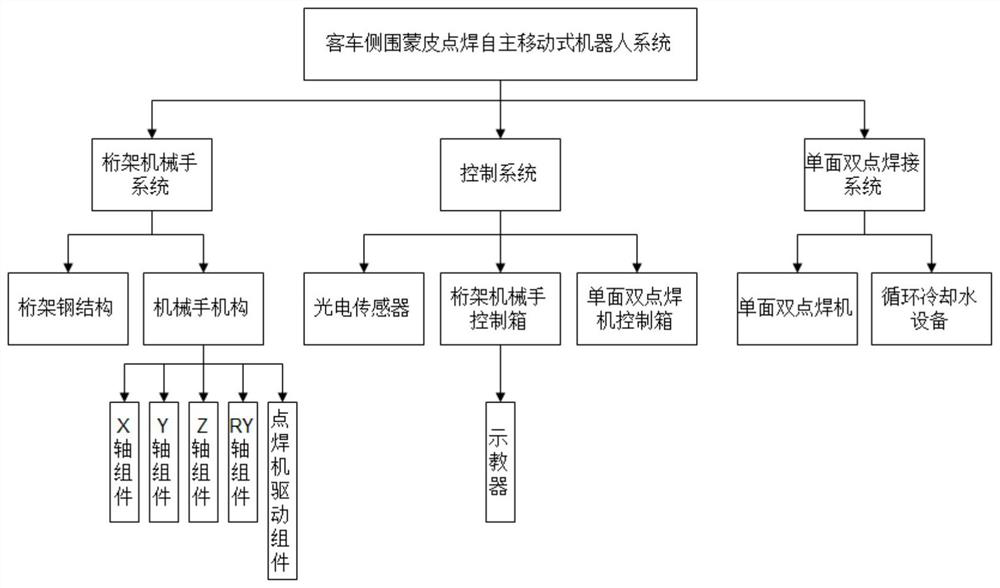

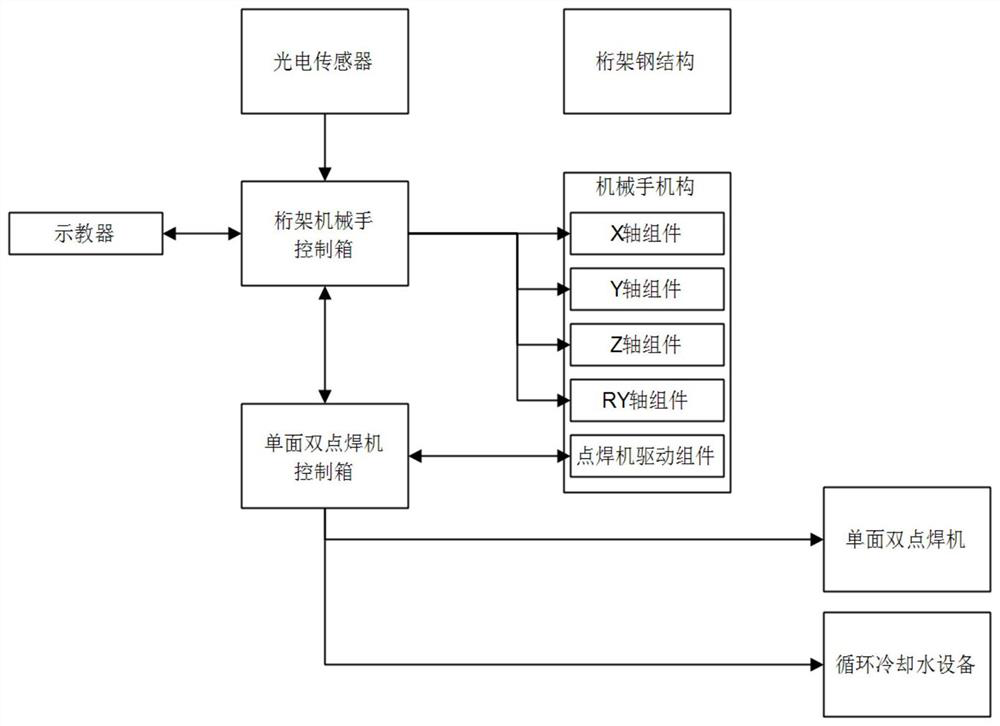

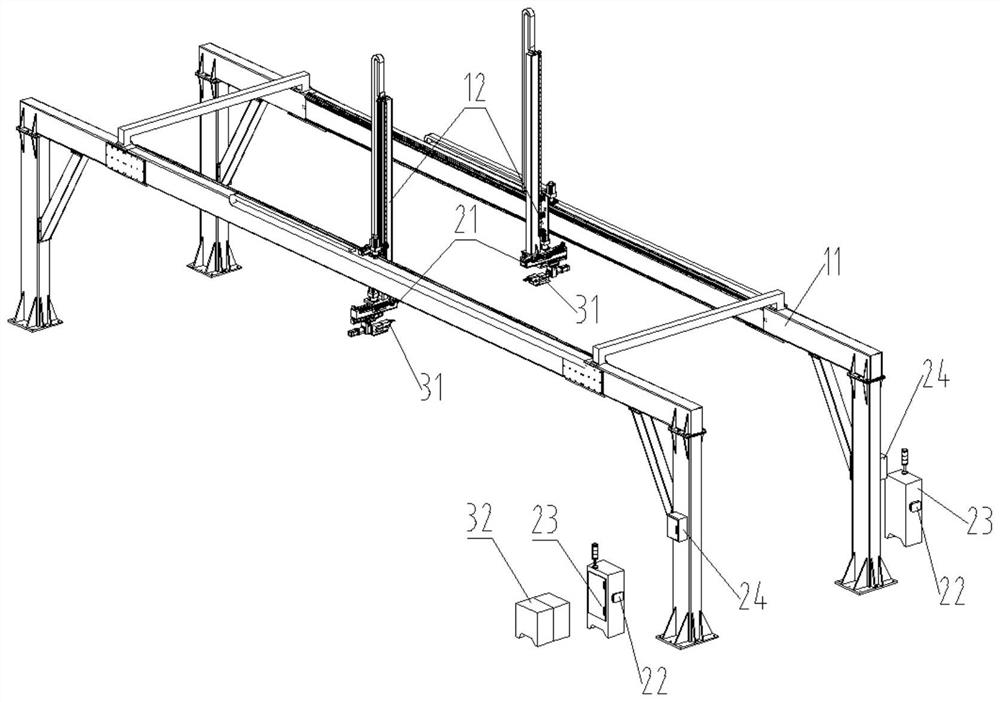

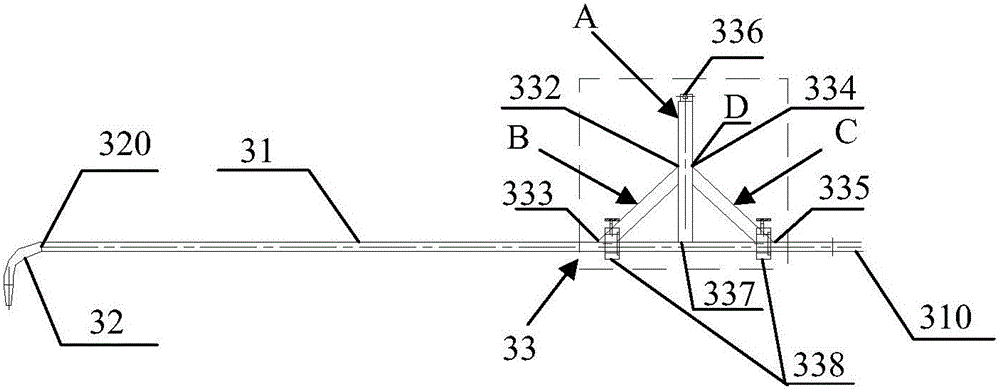

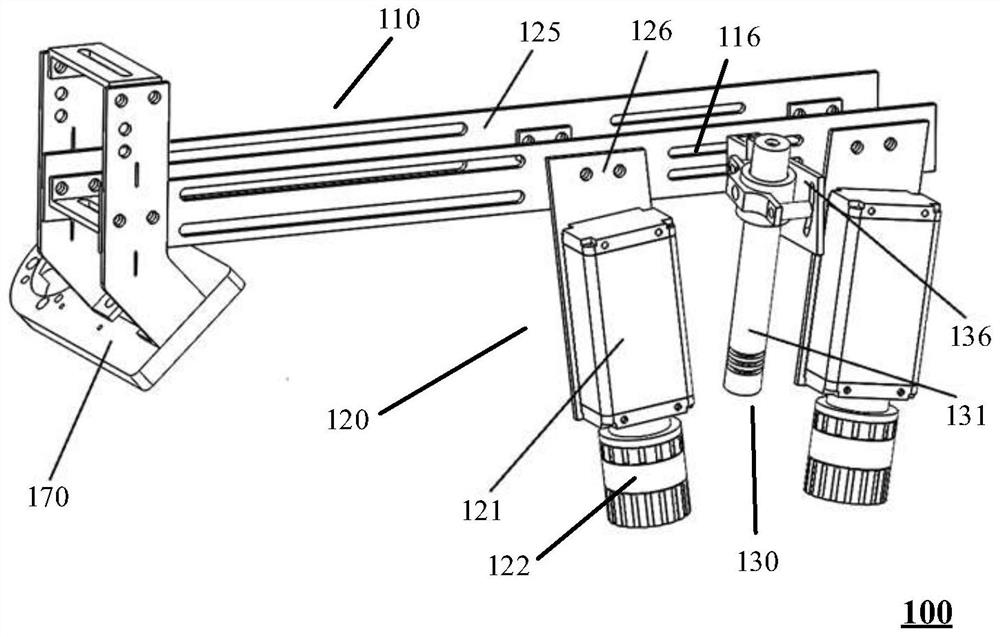

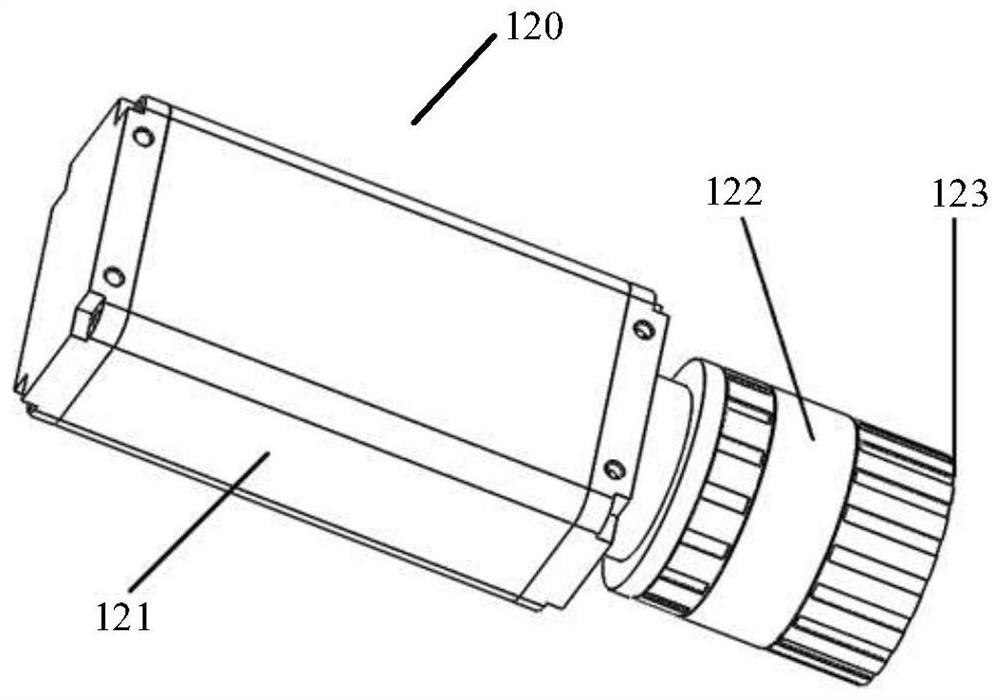

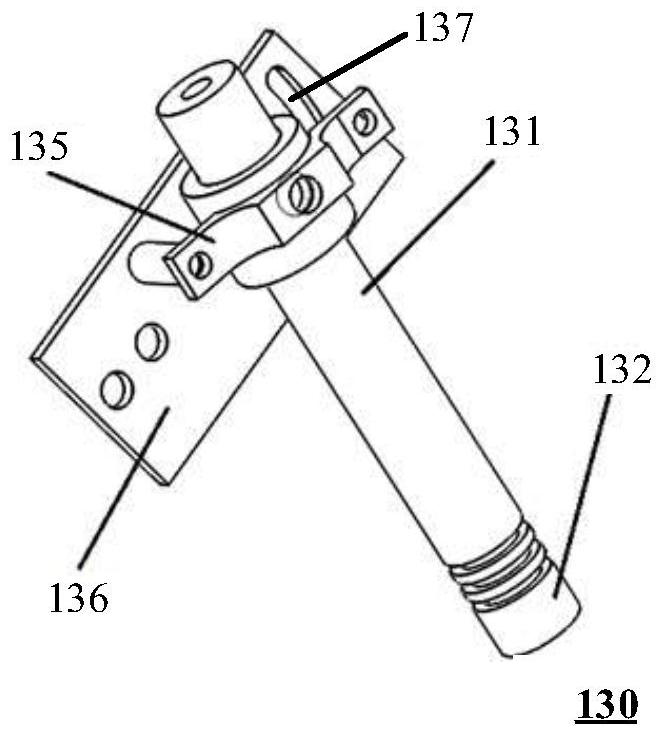

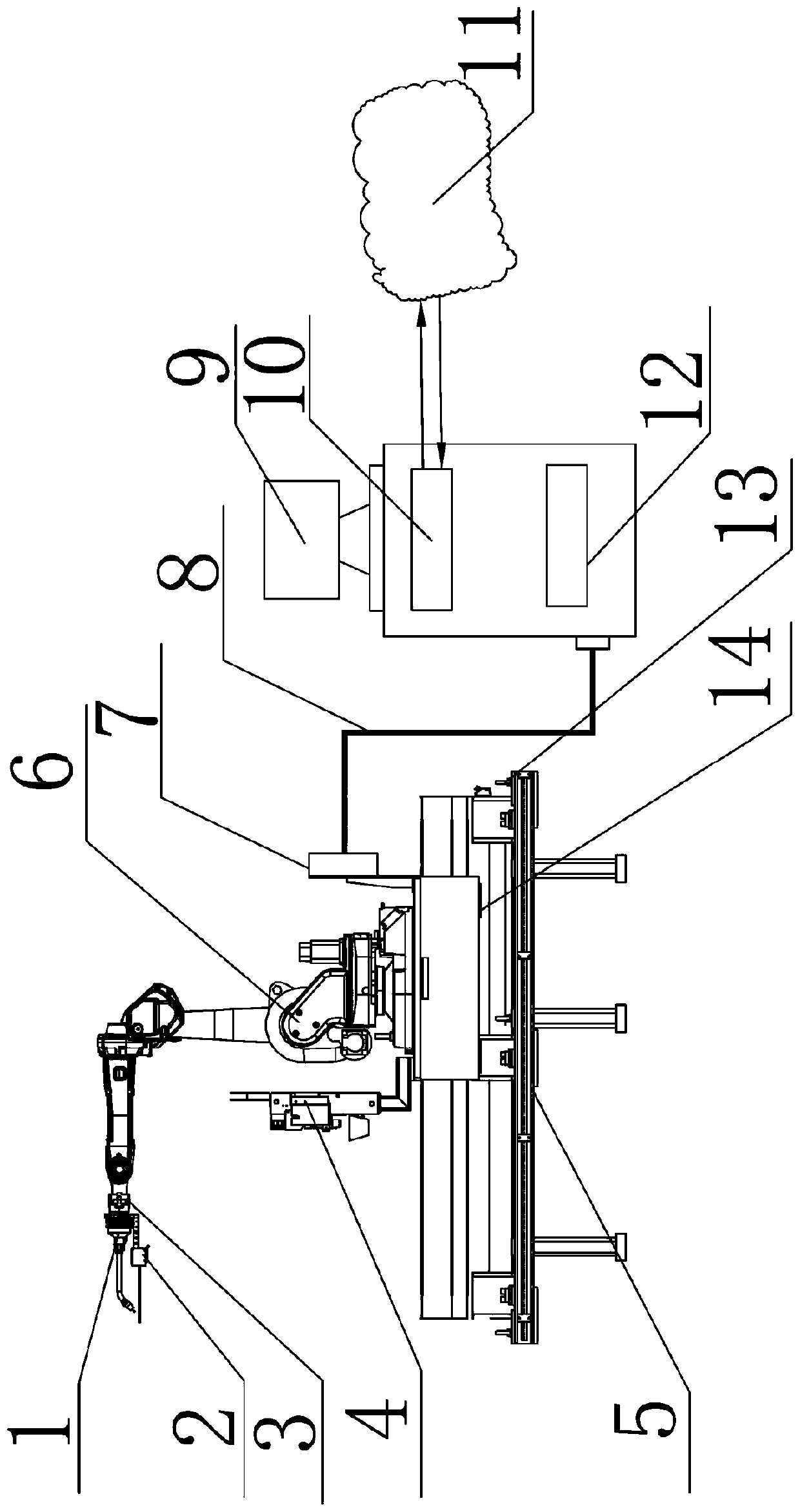

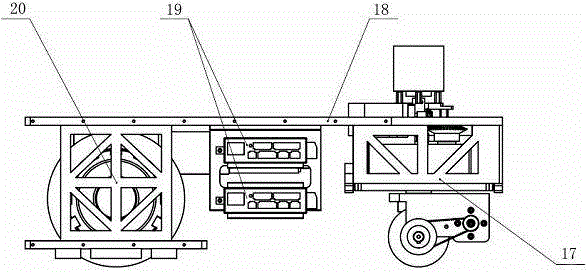

Autonomous mobile robot system for spot welding of passenger car side wall skin, and working method

PendingCN112355453ARealize intelligent weldingReduce labor intensityProgramme-controlled manipulatorResistance electrode holdersMachineManipulator system

The invention relates to the technical field of car body skin welding, in particular to an autonomous mobile robot system for spot welding of a passenger car side wall skin and a working method. The autonomous mobile robot system for spot welding of the passenger car side wall skin comprises a truss manipulator system, a control system and a single-face double-spot welding system, wherein the single-face double-spot welding system comprises a single-face double-spot welding machine; the truss manipulator system comprises a truss steel structure and a manipulator mechanism which is arranged onthe truss steel structure and used for moving the single-face double-spot welding machine; and the control system comprises a demonstrator, a truss manipulator control box and a single-face double-spot welding machine control box. The autonomous mobile robot system for spot welding of the passenger car side wall skin provided by the invention can not influence existing equipment and personnel operation space, is suitable for arrangement shapes of skin welding spots of various different vehicle types, has the functions of automatic locating and automatic moving of the positions of the welding spots, achieves automatic spot welding of the passenger car side wall skin, is beneficial to reducing the labor intensity of operators, and is high in production efficiency, uniform in welding spot distribution and good in welding quality.

Owner:上万清源智动车有限公司 +1

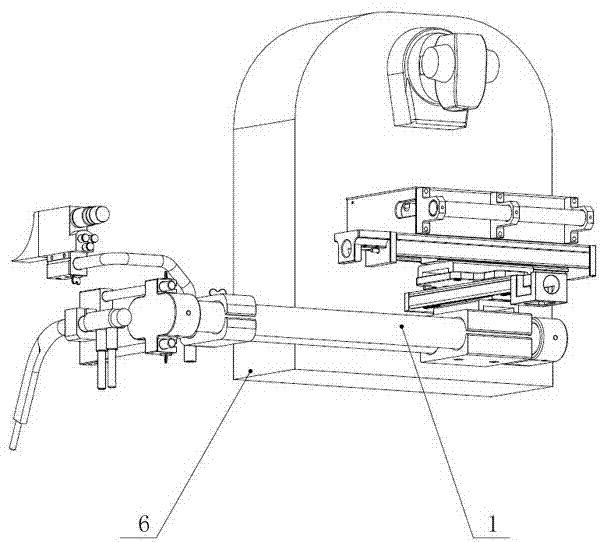

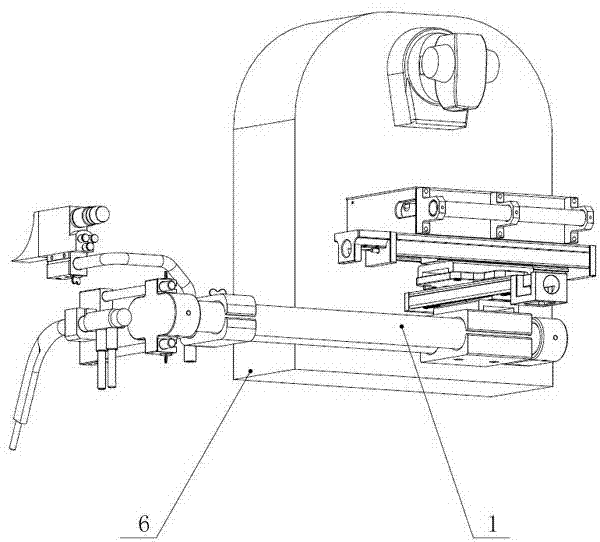

Automatic regulating device for argon arc welding machine table

PendingCN106984888AAdd adaptive functionImprove work efficiencyArc welding apparatusProcess engineeringAuto regulation

The invention discloses an automatic regulating device for an argon arc welding machine table. A movable rheostat body on a slide rheostat penetrates into a fixed support and is fixedly connected with the fixed support through a slide rheostat fixing jackscrew. A guide rod on the slide rheostat is connected with a bakelite support in a working tube, and the bakelite support is specifically arranged in the far end of the working tube. By the adoption of the automatic regulating device, the problem that welding cannot be conducted automatically according to external diameter change of products in traditional argon arc welding is solved, the self-adaption function is added, working efficiency is improved and operation is made convenient.

Owner:上乘精密科技(苏州)有限公司

A Gas Shielded Welding Oscillator with Seam Tracking Function

ActiveCN104475926BAchieve compensationImprove adaptabilityElectrode supporting devicesElectrical controlEngineering

The invention discloses a gas shielded welding oscillator with a welding joint tracing function and belongs to a welding automation control device. The gas shielded welding oscillator with the welding joint tracing function mainly solves the technical problems of large welding joint gap and the like due to the fact that an existing oscillator is incapable of detecting and compensating a workpiece processing error, an assembly error, welding heat deformation and the like errors in real time. According to the technical scheme, the gas shielded welding oscillator with the welding joint tracing function comprises a Hall sensor, a welding joint tracing controller with a welding joint gap compensation function, a driver and a double-effect swinging mechanism, the welding joint tracing controller detects and compensates the welding joint gap caused by workpiece processing errors, assembly errors and welding heat deformation in real time according to signals gathered by the Hall sensor, and under the electric control and the driver control, the double-effect swinging mechanism freely changes between horizontal swinging and pendular swinging and automatically regulates the swinging amplitude and swinging frequency. The gas shielded welding oscillator with the welding joint tracing function is mainly used for welding.

Owner:湖南艾克机器人有限公司

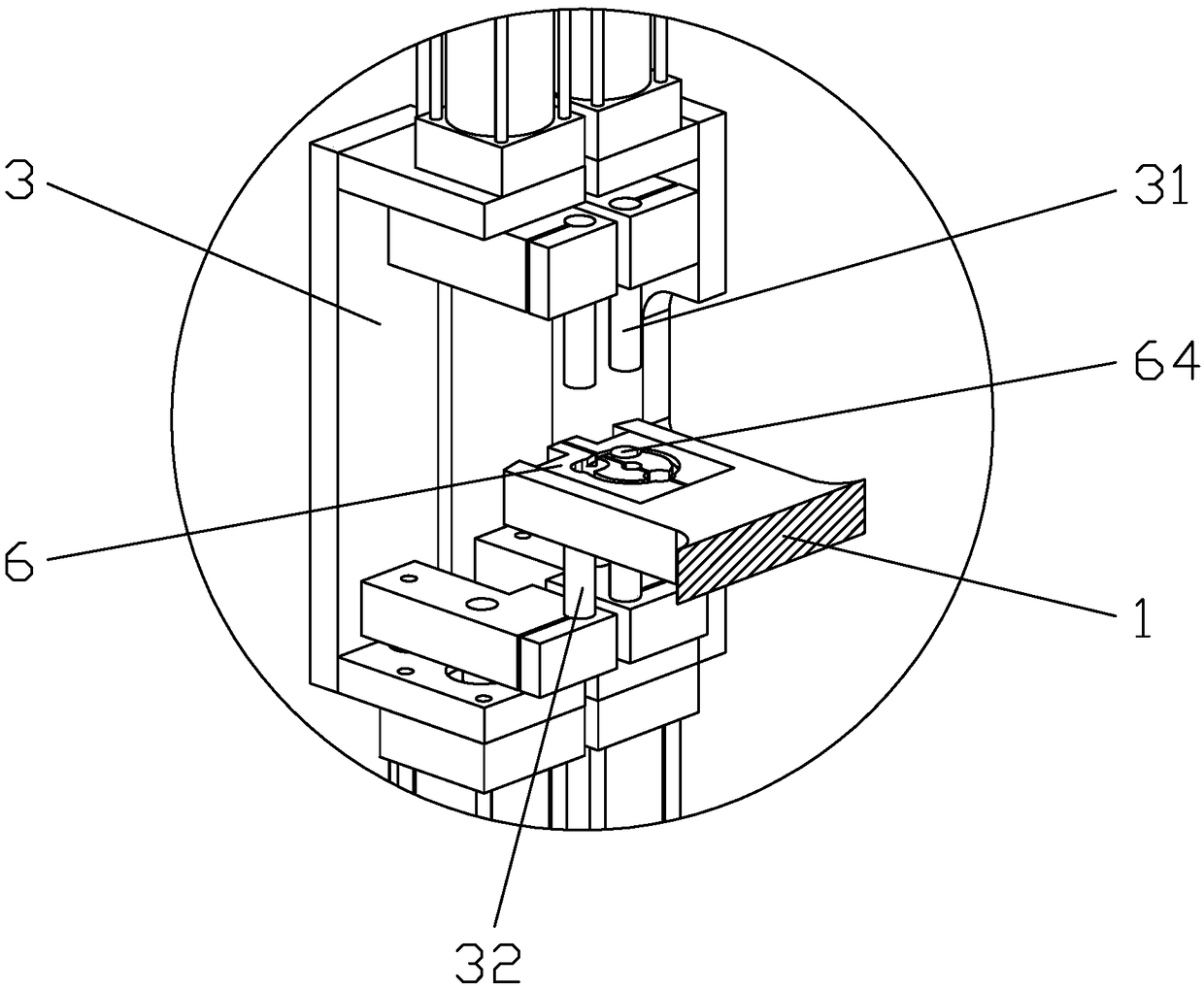

Welding device

ActiveCN105965181ARealize intelligent weldingReduce workloadWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCantilever

The invention provides a welding device. The welding device comprises a rotary mechanism, a welding control system, a cantilever welding mechanism and a position adjustment mechanism. The cantilever welding mechanism comprises a cantilever and a welding gun head. The welding control system is electrically connected with the rotary mechanism and the first end of the position adjustment mechanism. The second end of the position adjustment mechanism is connected with the first end of the cantilever. The welding gun head connected with a welding machine is arranged at the second end of the cantilever. The welding control system is used for controlling a part to be welded to rotate, controlling the position adjustment mechanism to move the welding gun head to the preset welding position of the part to be welded and controlling the welding gun head to move horizontally, so that the part to be welded is welded. The welding device realizes intelligent welding of small-size cylinder-class parts to be welded, thereby greatly relieving the work burden on operators and improving welding accuracy and welding production efficiency.

Owner:PINGAN COAL MINING ENG RES INST CO LTD +1

Visual positioning method and system and computing equipment

InactiveCN113319411ARealize intelligent weldingPrecision weldingWelding accessoriesFillet weldEngineering

The invention discloses a visual positioning method, which is executed in computing equipment and comprises the following steps of: acquiring a welding seam image on the surface of a workpiece; determining welding seam feature points and image coordinates thereof on the welding seam image based on the welding seam extraction template; and determining world coordinates of the weld joint feature points based on the image coordinates, wherein the workpiece is welded based on the world coordinates of the weld joint feature points. The invention also discloses a visual positioning system, a visual positioning method executed in the system and computing equipment. According to the visual positioning method, accurate positioning of the fillet weld coordinates can be achieved, so that the efficiency of weld extraction and weld positioning is improved.

Owner:HUNAN UNIV

Automatic argon arc welding device

PendingCN106903400AEasy to controlRealize intelligent weldingElectrode supporting devicesElectric machineryEngineering

The invention discloses an automatic argon arc welding device. A vertical support is vertically connected to a transverse support. A welding gun translation device is connected to the vertical support through a translation trough arranged on the welding gun translation device. A movable rod in the translation trough is connected with a motor. A fixing plate is connected with the movable rod. A welding gun head fixing frame is connected to one end of the fixing plate. An argon arc welding gun head is fixed to the welding gun head fixing frame. A connecting part is arranged at the end, close to the argon arc welding gun head, of the upper portion of the fixing plate. A wire feeding head is connected to the connecting part through an adjusting part. An automatic adjusting device is connected with the end, away from the argon arc welding gun head, of the lower portion of the fixing plate through a fixing support at one end of the automatic adjusting device. The problem that traditional argon arc welding cannot be conducted according to the product outer diameter changes automatically is solved, the self-adaptation function is additionally achieved, the working efficiency is improved, operation is convenient, and the service life is long.

Owner:上乘精密科技(苏州)有限公司

Welding robot for ship assembly grillage structure

PendingCN109746602ARealize acquisitionRealize the display effectWelding/cutting auxillary devicesAuxillary welding devicesRobot controlManipulator

The invention provides a welding robot for a ship assembly grillage structure. The welding robot for the ship assembly grillage structure comprises a support. The support is provided with a guide railand a lifting hole. The welding robot further comprises a robot body, a welding gun, a welding gun cleaner, a visual scanning module used for obtaining three-dimensional data of a welding point, a data collecting module, a control module, an internet-of-things platform and a robot control module. The robot body is arranged on the guide rail and moves along the guide rail. The welding gun is arranged at the tail end of a mechanical arm of the robot body. The visual scanning module is arranged on the welding gun. The welding gun cleaner is adjacent to the robot body. The input end of the robotbody is connected to the robot control module. The output end of the visual scanning module is connected to the input end of the data collecting module. The output end of the data collecting module isconnected to the controller. The robot control module is connected to the control module. The control module is connected to the internet-of things platform.

Owner:BEIBU GULF UNIV

welding device

ActiveCN105965181BRealize intelligent weldingReduce workloadWelding/cutting auxillary devicesAuxillary welding devicesControl systemEngineering

The invention provides a welding device. The welding device comprises a rotary mechanism, a welding control system, a cantilever welding mechanism and a position adjustment mechanism. The cantilever welding mechanism comprises a cantilever and a welding gun head. The welding control system is electrically connected with the rotary mechanism and the first end of the position adjustment mechanism. The second end of the position adjustment mechanism is connected with the first end of the cantilever. The welding gun head connected with a welding machine is arranged at the second end of the cantilever. The welding control system is used for controlling a part to be welded to rotate, controlling the position adjustment mechanism to move the welding gun head to the preset welding position of the part to be welded and controlling the welding gun head to move horizontally, so that the part to be welded is welded. The welding device realizes intelligent welding of small-size cylinder-class parts to be welded, thereby greatly relieving the work burden on operators and improving welding accuracy and welding production efficiency.

Owner:PINGAN COAL MINING ENG RES INST CO LTD +1

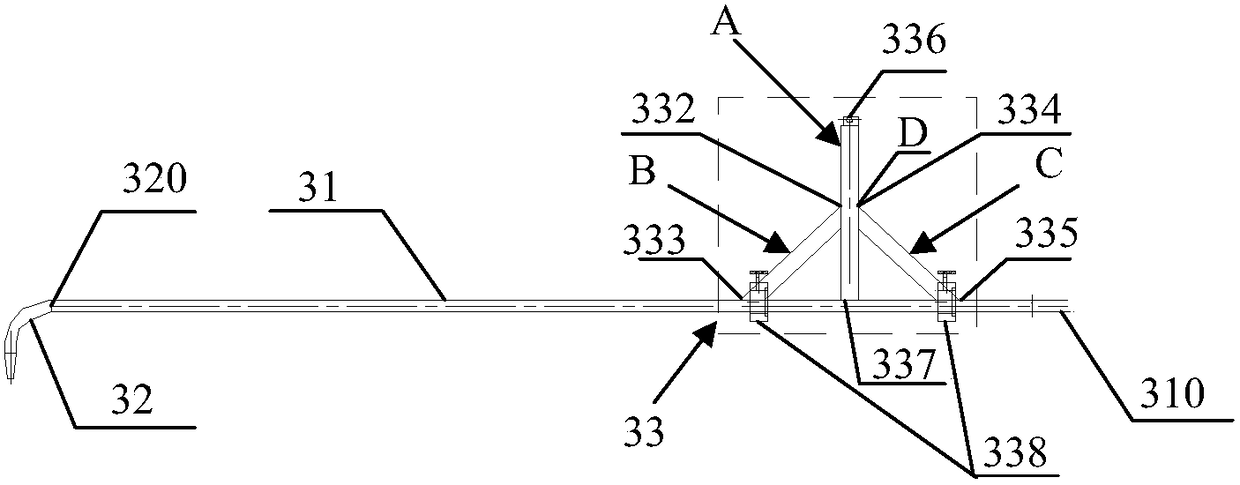

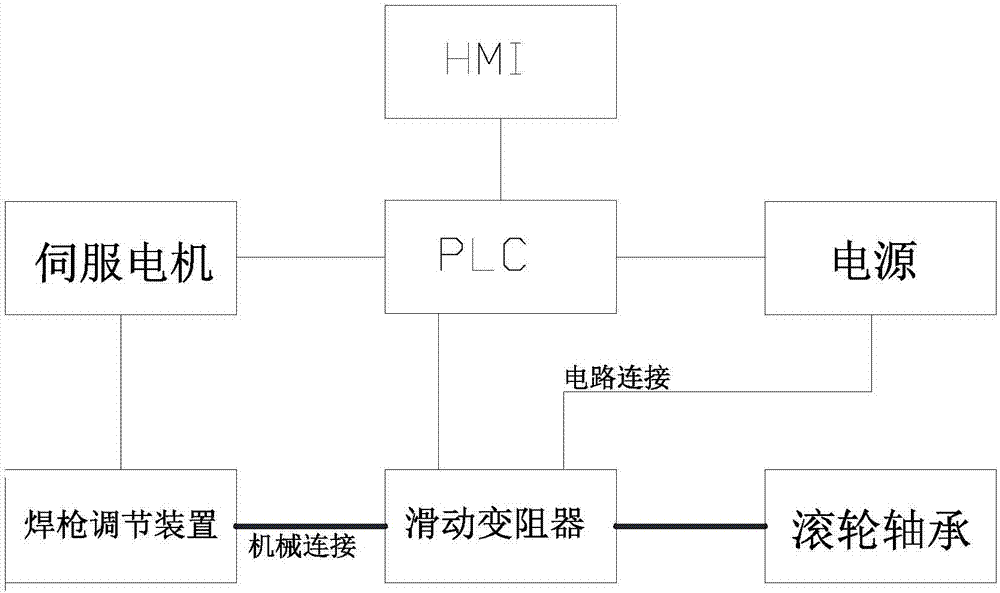

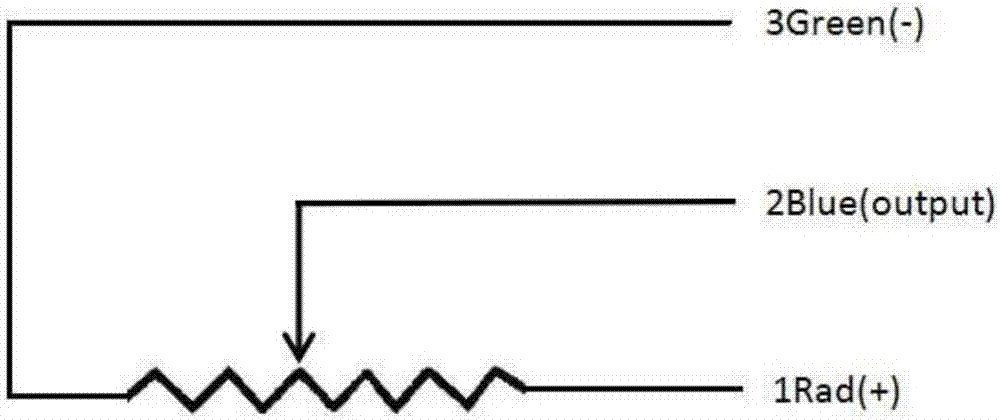

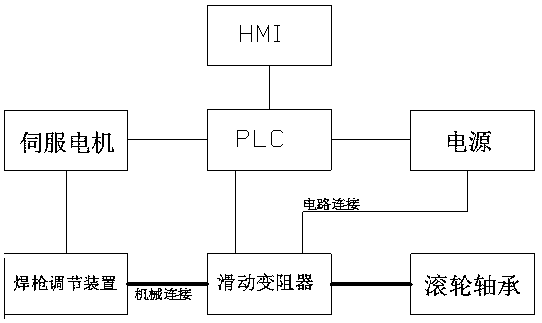

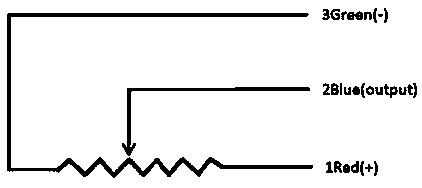

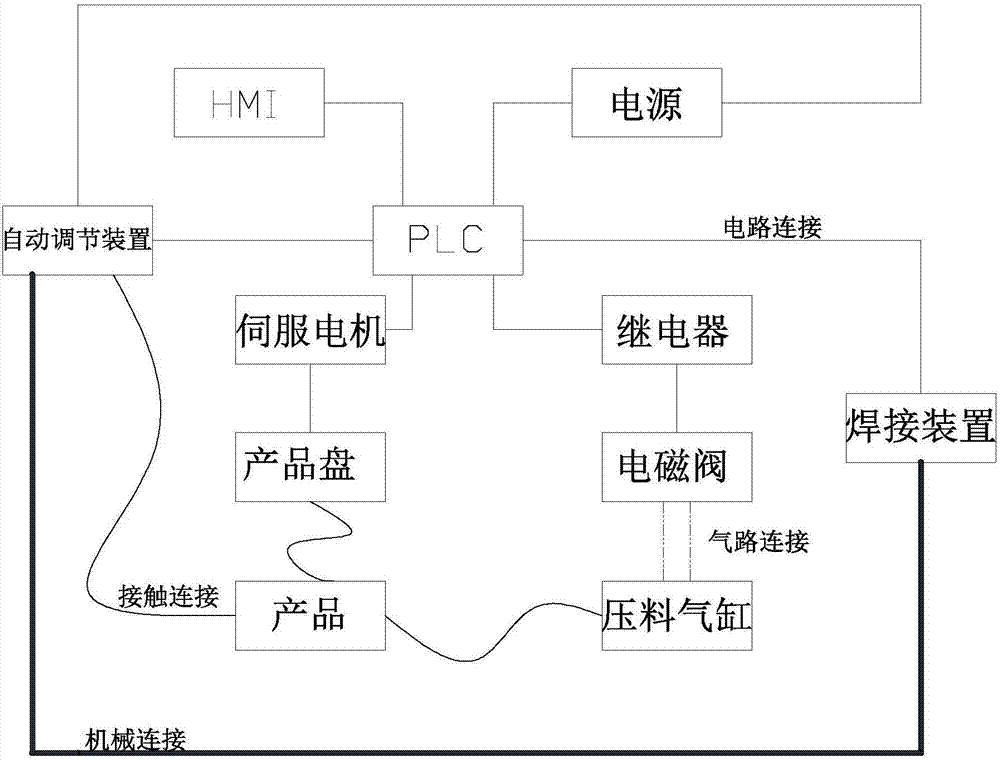

Control system of argon arc welding stand automatic adjusting device

ActiveCN107138831ARealize intelligent weldingOvercome the problem of not being able to automatically weld according to product outer diameter changesWelding accessoriesControl systemControl circuit

The invention discloses a control system of an argon arc welding stand automatic adjusting device. An HMI and a PLC are in circuit connection; the PLC is in circuit connection with a servo motor; the servo motor is connected with a welding gun adjusting device to form a control circuit; and the PLC, a slide rheostat and a power supply are pairwise in circuit connection to form acquiring circuits. The control system overcomes the difficulty of incapability of automatically welding according to the product outer diameter change by traditional argon arc welding, improves the self-adaption function of argon arc welding, improves the working efficiency, is suitable for welding and positioning of such irregular circular surfaces as circles or ellipses, and can automatically adjust the welding position gap according to the welding surface position.

Owner:山东先罗新型建材科技开发有限公司

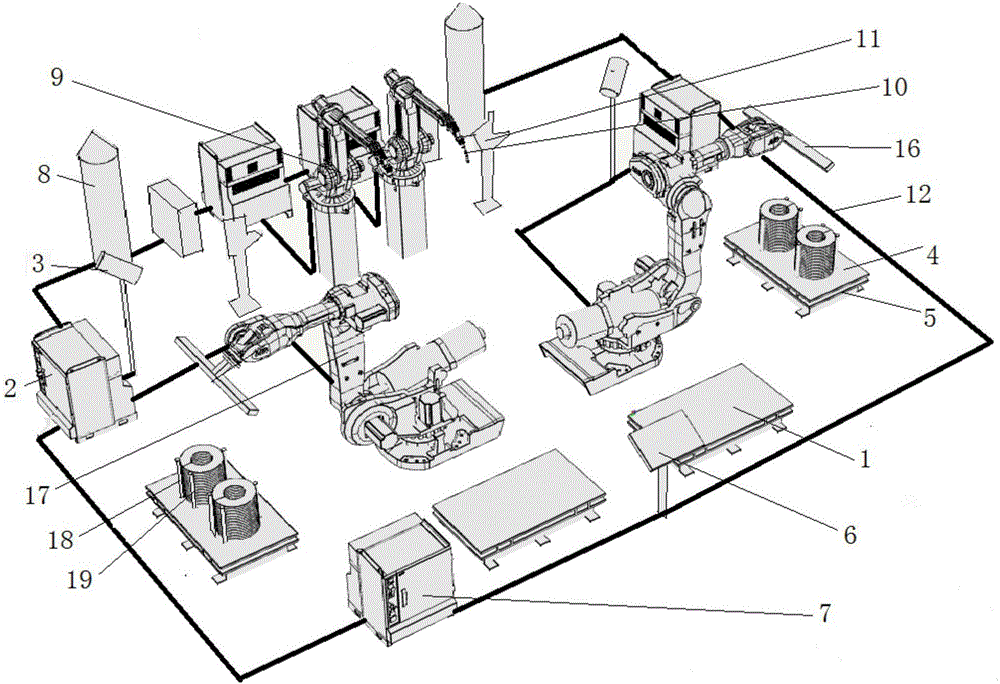

A multi-station robot intelligent welding system for pipe pile end plate

InactiveCN105397244BTake advantage ofRealize intelligent weldingManipulatorWelding accessoriesRobotic systemsHuman–machine interface

The invention discloses a multi-station robot intelligent welding system for pipe piling sheets. The multi-station robot intelligent welding system comprises a control system, a clamp system, a machine vision system, a robot system, a welding system and a safety protection system, wherein the control system comprises a robot control cabinet, a PLC control cabinet, a machine vision system and a man-machine interface; the robot system comprises two supplying robots, two welding robots and a feeding robot; the two supplying robots are placed in a back-to-back manner; the two welding robots are placed at front middle positions of the two supplying robots side by side; the PLC control cabinet is in communication with the robot control cabinet; the robot control cabinet controls movement of a robot body; the welding system is connected with a welding robot control cabinet; and a welding robot body controls a welding gun to finish welding. By the multi-station robot intelligent welding system, positions and widths of welded joints can be recognized accurately, and information of the welded joints is recognized automatically; and the feeding robot feeds materials automatically, the labor intensity is reduced, and high automation of a whole process of feeding, supplying and welding is realized.

Owner:DALIAN UNIV OF TECH

Automatic curtain hanging ring welding machine

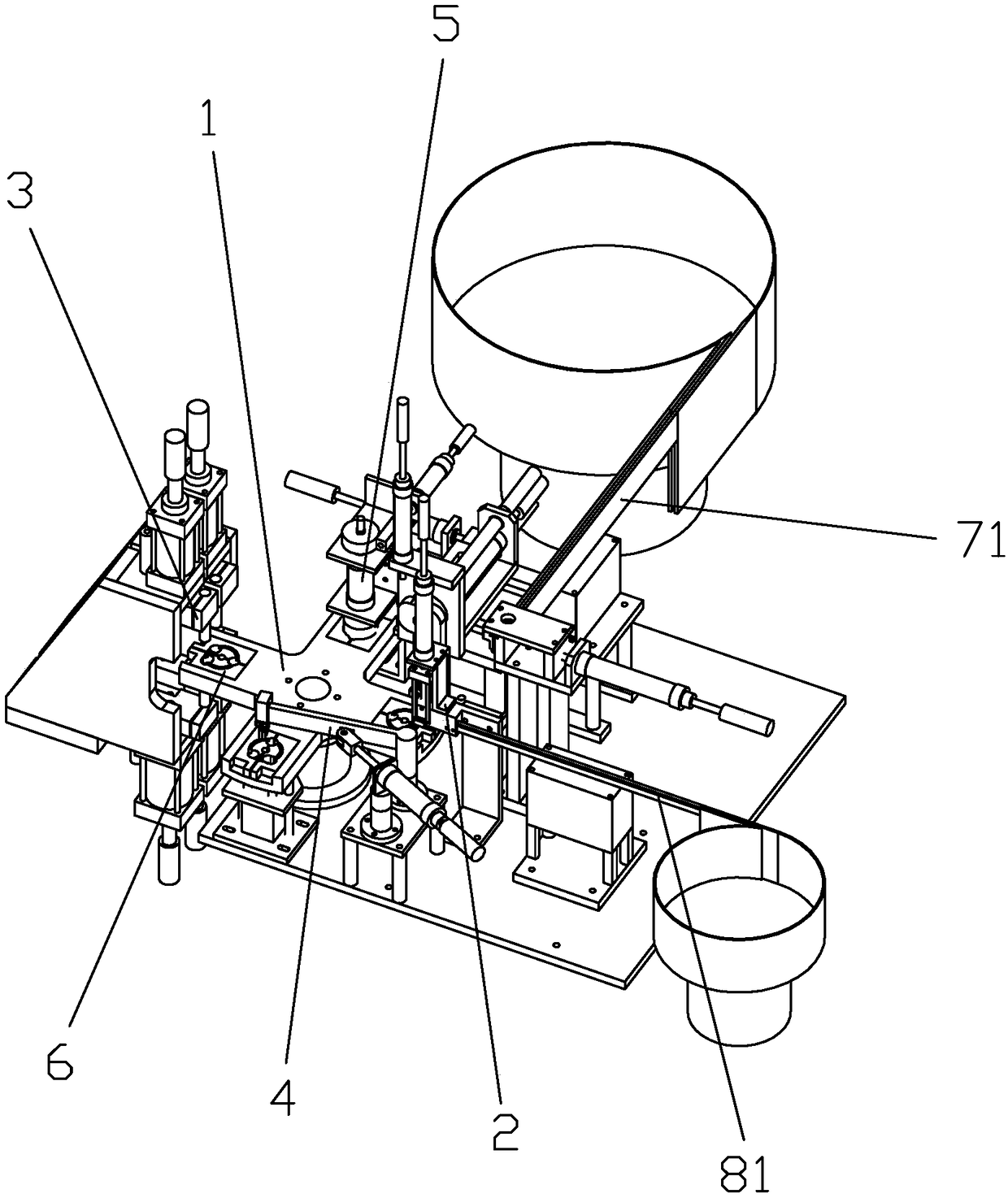

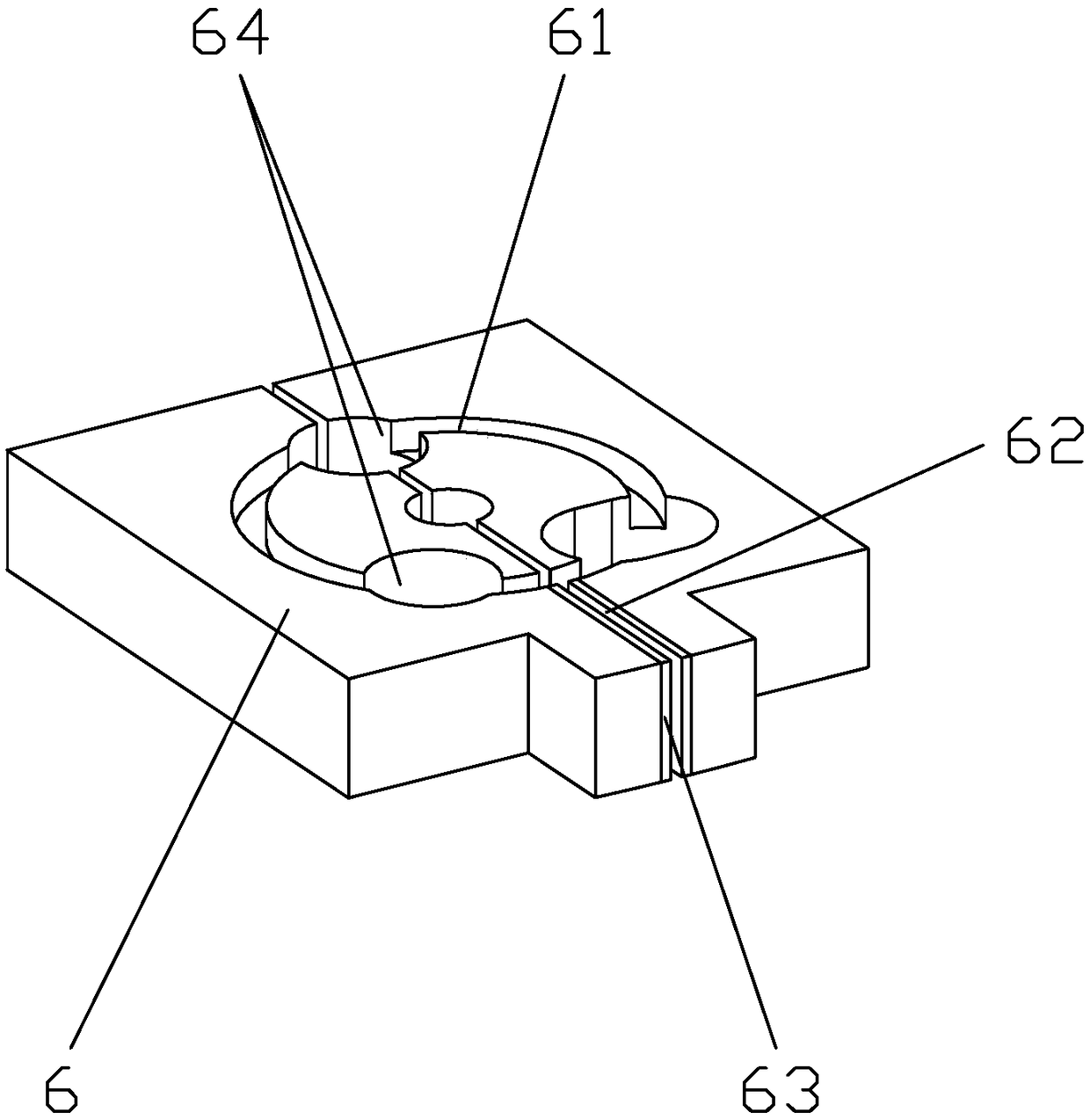

PendingCN108747122ARealize intelligent weldingFully automatedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringIntelligent control system

The invention discloses an automatic curtain hanging ring welding machine. The automatic curtain hanging ring welding machine comprises a rotation workbench and a station on the rotation workbench. Afeeding module, a welding module and a workpiece taking module are sequentially distributed around the rotation workbench. The station is provided with a workpiece die. The workpiece die comprises a circular ring groove corresponding to a workpiece main hanging ring, and a vertical slot corresponding to a workpiece connecting ring. The vertical slot is provided with a high-melting-point clamping plate. The welding module comprises a welding gun corresponding to the position of the vertical slot and upper pressing rods corresponding to the position of the side, facing the vertical slot, of thecircular ring groove. The welding machine can finish the whole curtain hanging ring welding process, an intelligent control system is matched so that curtain hanging ring welding intelligence and automation can be achieved, and the production efficiency is greatly improved.

Owner:FOSHAN HAOBANG MACHINERY CO LTD

A Method for Optimizing Robotic Welding Process Parameters Based on CBR and RBR

ActiveCN109865916BImprove formulation efficiencyAchieve reuseProgramme-controlled manipulatorWelding accessoriesProcess engineeringRobot welding

The invention relates to a robot welding technology parameter optimization method based on CBR and RBR, and belongs to the technical field of robot welding. The robot welding technology parameter optimization method involves a welding technology input module, a welding technology expert system and a welding technology output module. The welding technology input module receives welding tasks and welding resources and further submits the welding tasks and the welding resources to the welding technology expert system. A query engine in the welding technology expert system reuses historical welding cases, and it enters a reasoning engine for case-based reasoning on the basis of rules if no similar welding technology cases exist. A range value exists in the reasoned welding technology, particleswarm optimization in a welding technology parameter optimization module is adopted for multi-objective optimization of welding technology parameters, the optimal welding technology parameter combination is determined, an exact value is acquired for a welding robot to execute, and robot welding intelligence is realized. Production efficiency can be improved and the effect is remarkable.

Owner:SHANDONG UNIV

Intelligent multi-welding-head ultrasonic welding machine

InactiveCN108995223AAvoid precisionAvoid welding with large gapsDomestic articlesIntelligent lightingUltrasonic welding

The invention discloses an intelligent multi-welding-head ultrasonic welding machine. The intelligent multi-welding-head ultrasonic welding machine comprises a machine frame, welding units arranged inthe machine frame, a workpiece positioning device arranged in the machine frame, and an electrical control cabinet. The intelligent multi-welding-head ultrasonic welding machine is characterized in that the welding units arranged in the machine frame form a multi-head welding set, the multi-head welding set is annularly arranged on a base connection plate and composed of the seven welding units;and the workpiece positioning device comprises a fixing plate connected into the machine frame, a driving air cylinder arranged on the fixing plate, a die connection plate connected to the output endof the driving air cylinder, and the like. The intelligent multi-welding-head ultrasonic welding machine is provided with the multi-head welding set composed of the multiple welding units, and the workpiece positioning device, so that welding is completed at a time, welding vibration is reduced, and the problems that a motormeter cover is not high in precision, large in welded seam and poor in welding quality in the welding process are solved. Meanwhile, the intelligent multi-welding-head ultrasonic welding machine is simple in structure and convenient to use, intelligent welding is achieved,and the welding efficiency and the product quality are improved.

Owner:WUHU XINBAO ULTRASONIC EQUIP

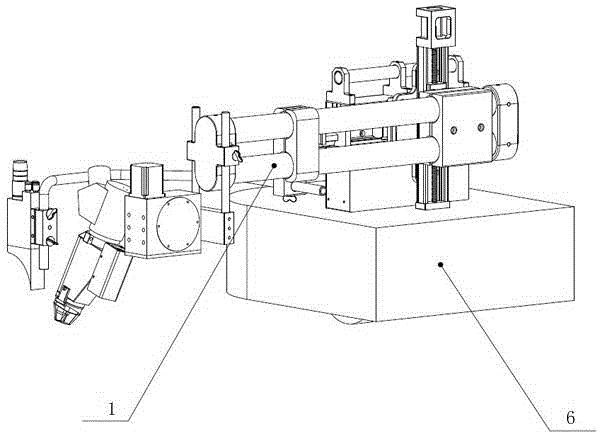

An autonomous mobile twin wire welding robot system for medium and heavy plate welding

ActiveCN102672316BImprove performanceRealize environmental monitoringArc welding apparatusRobotic systemsControl system

The invention belongs to the technical field of the welding of a robot, particularly relates to an autonomous movable type double-wire welding robot system for welding medium plates, comprising a robot body, a control system and a double-wire welding system, wherein the robot body comprises a crawling mechanism and an operation mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; and the double-wire welding system comprises a double-wire welding gun, a double-wire welding power source, a double-wire wire feeder, and a protecting gas and welding cooling system. The system has the advantage that welded joints can be autonomously identified and tracked. The system has the functions of long-distance welding parameter setting and on-line adjustment and can autonomously identifying the center point of a groove; a multi-free degree cradle head can be adopted, so that the environment monitoring of a workpiece can be realized, the macroscopic operation of an initial point before welding can be completed, and the intelligent welding can be realized; and a molten pool monitoring sensor can be adopted, so that the posture adjustment of the double-wire welding gun can be realized, and the molten pool in the process of welding can be monitored, i.e. the microscopic autonomy can be realized.

Owner:DONGFANG ELECTRIC CORP LTD

A control system for an automatic adjustment device of an argon arc welding machine

ActiveCN107138831BRealize intelligent weldingImprove adaptive functionWelding accessoriesControl systemEngineering

The invention discloses a control system of an argon arc welding stand automatic adjusting device. An HMI and a PLC are in circuit connection; the PLC is in circuit connection with a servo motor; the servo motor is connected with a welding gun adjusting device to form a control circuit; and the PLC, a slide rheostat and a power supply are pairwise in circuit connection to form acquiring circuits. The control system overcomes the difficulty of incapability of automatically welding according to the product outer diameter change by traditional argon arc welding, improves the self-adaption function of argon arc welding, improves the working efficiency, is suitable for welding and positioning of such irregular circular surfaces as circles or ellipses, and can automatically adjust the welding position gap according to the welding surface position.

Owner:山东先罗新型建材科技开发有限公司

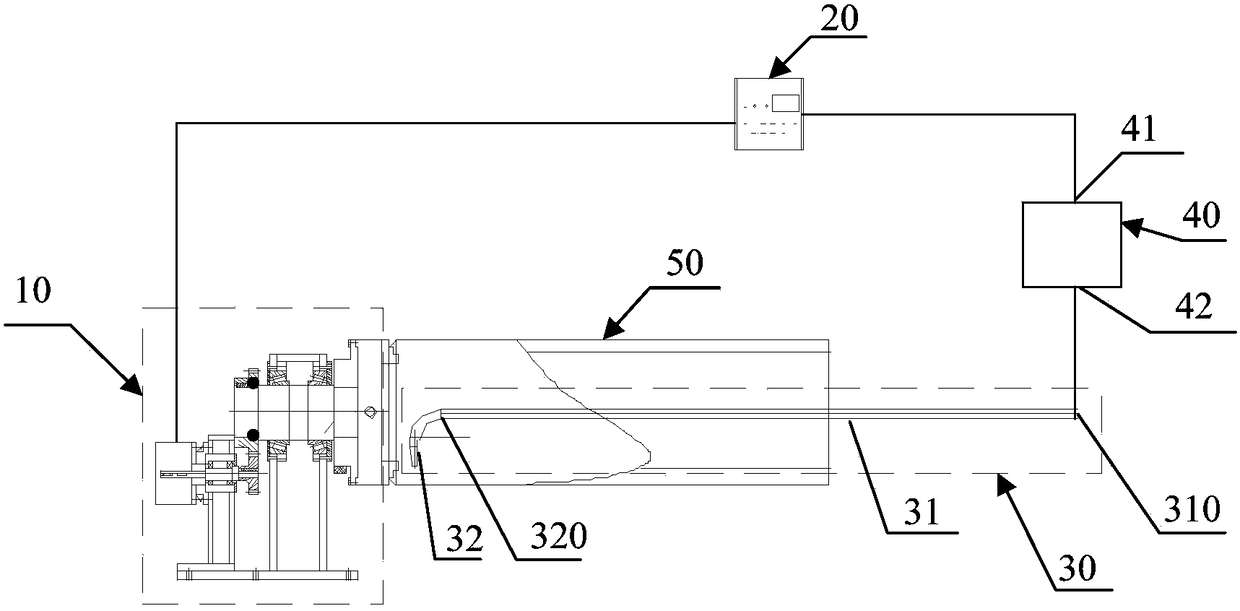

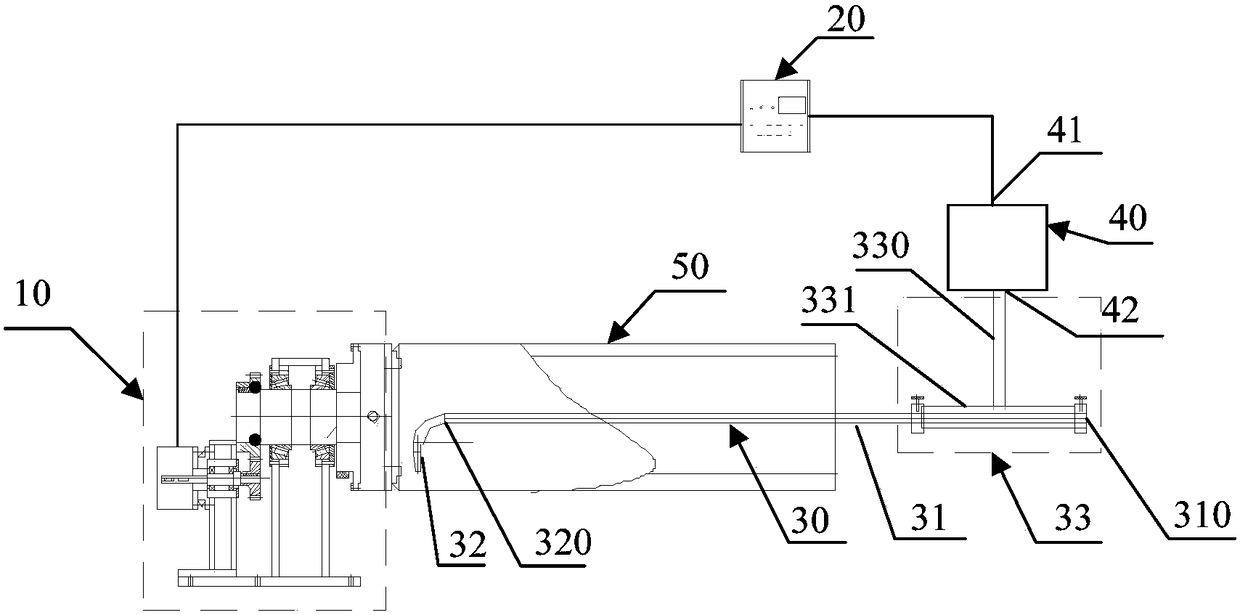

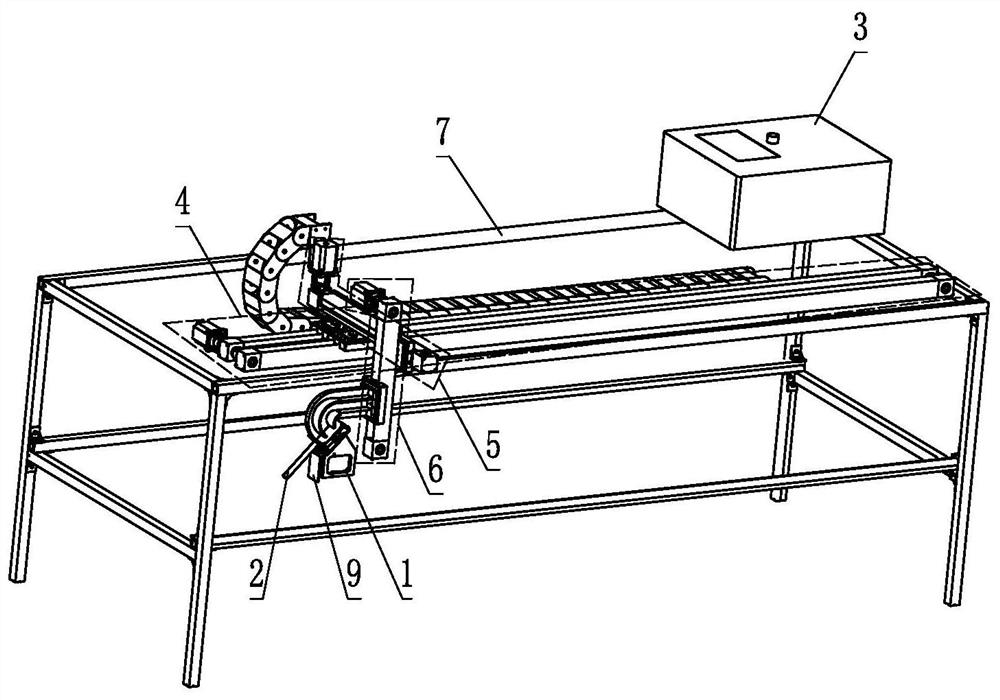

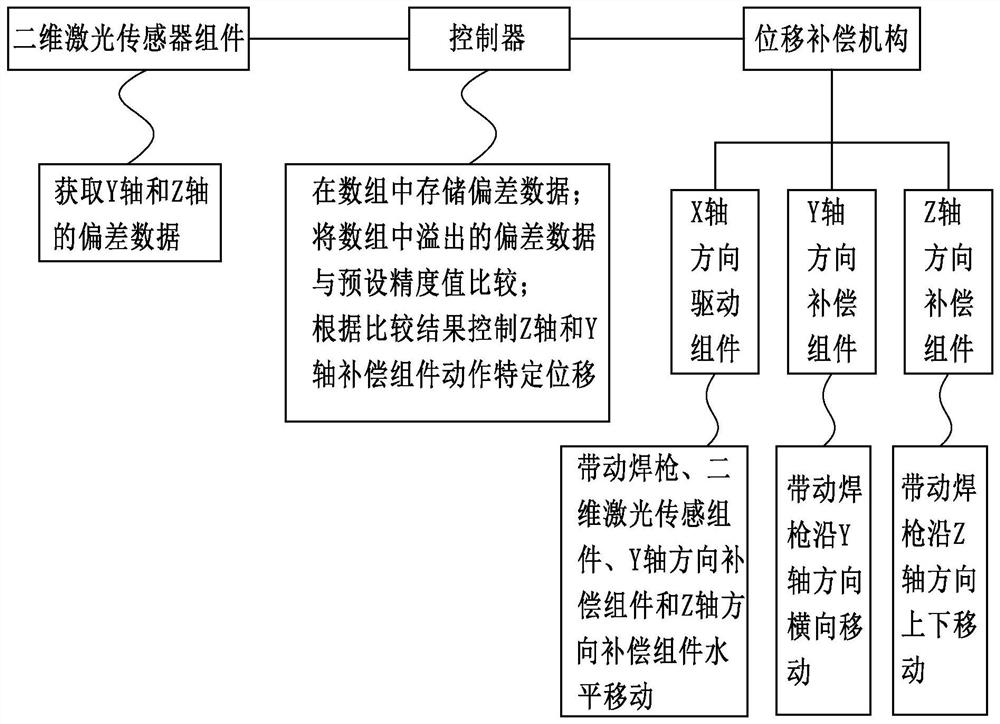

Welding seam tracking method for pressing roller welding

PendingCN113649673ARealize intelligent weldingMeet welding needsArc welding apparatusEngineeringWeld seam

The invention discloses a welding seam tracking method for suppressing roller welding. The welding seam tracking method is based on a welding seam tracking system of a two-dimensional laser sensing assembly, the two-dimensional laser sensing assembly acquires deviation data in real time and processes the deviation data in an array by adopting a first-in first-out storage algorithm and a comparison compensation mode. By adopting the first-in first-out data storage algorithm and the comparison compensation mode, the running paths of a welding gun on the Z axis and the Y axis can be tracked and compensated in real time, so that each welding step of the welding gun is compensated and corrected, the distance between the welding gun and a welding seam is ensured to be a specific height, the welding gun is also ensured to move along the welding seam, the phenomenon that an existing welding gun is prone to deviating from the welding seam in the welding process, so that the welding seam straightness and the suppression roundness deviate is avoided, meanwhile, intelligent welding of the suppression roller welding seam is achieved through the welding seam tracking method, manual participation does not need, and the problems that manual welding is low in efficiency, poor in quality, high in labor intensity, low in automation degree, harmful to human bodies and the like are solved.

Owner:TARIM UNIV

Autonomous mobile robot system for metal-inert-gas (MIG)/metal-active-gas (MAG) multilayer multipass welding of large thick plate

ActiveCN102689083BImprove performanceWith environmental monitoringElectrode supporting devicesDrive wheelVehicle frame

Owner:DONGFANG ELECTRIC CORP LTD

Autonomous mobile robot system for plasma metal-inert-gas (MIG) composite welding

ActiveCN102689100BImprove adsorption capacityImprove performanceWelding/cutting auxillary devicesAuxillary welding devicesMacro environmentWelding power supply

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile robot system for plasma metal-inert-gas (MIG) composite welding. The system comprises a robot body, a control system and a plasma MIG composite welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; and the plasma MIG composite welding system comprises a digitized MIG welding power supply, a plasma power supply, a wire feeding machine, shielding gas, a plasma welding gun and an MIG welding gun. The system has the advantages that a plasma MIG composite welding robot can adapt to an all-position welding mode of a large-sized steel structure; due to the adoption of an adsorption type crawling mechanism, the system can flexibly move; and due to the adoption of a laser welding seam tracking sensor and the arrangement of a macro-environment monitoring and molten pool monitoring system, the system can meet swinging requirements, control requirements and movement requirements in the all-position welding process of large thick plates.

Owner:DONGFANG ELECTRIC CORP LTD

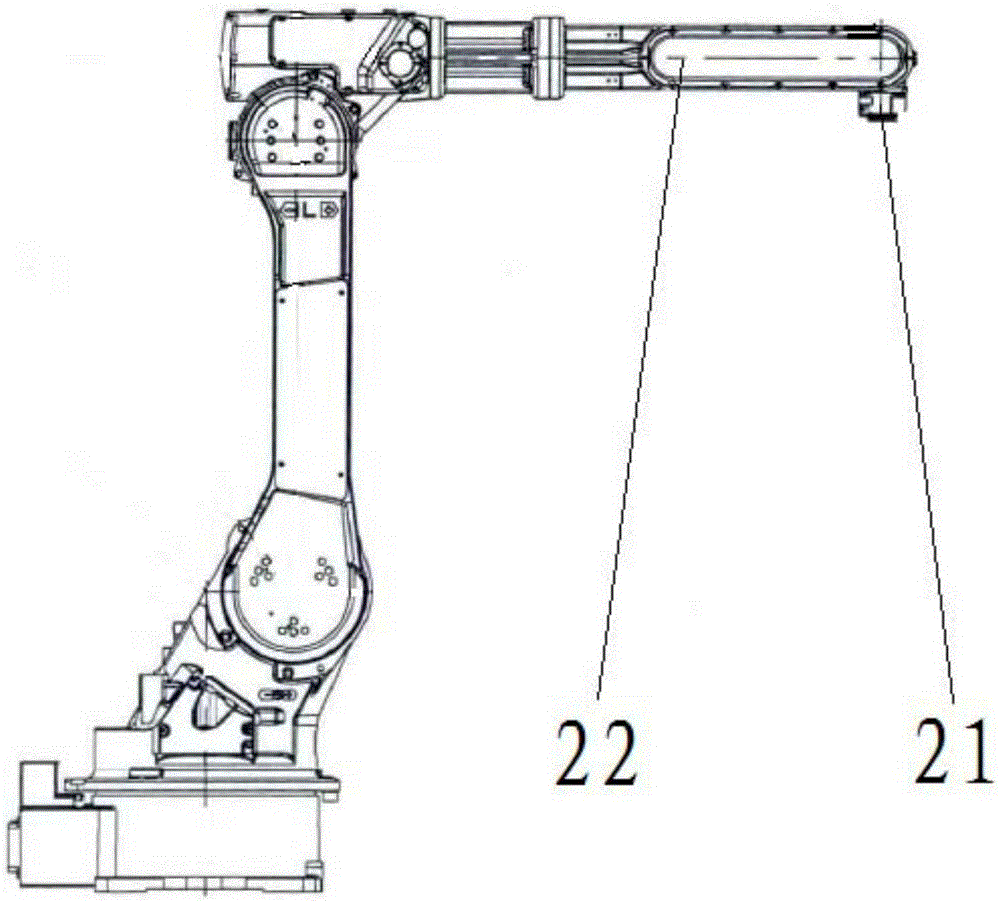

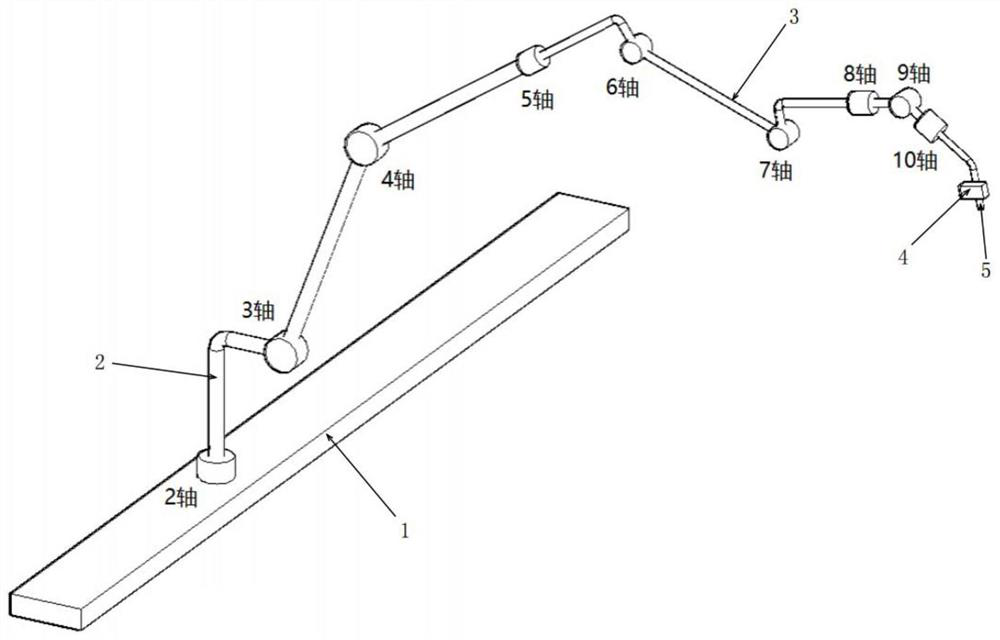

A robot intelligent welding method with redundant degrees of freedom with vision

ActiveCN113681133BIncrease the number of degrees of freedomFlexible Adaptive WeldingElectrode holder supportersWelding accessoriesControl engineering3d camera

The invention discloses an intelligent welding method of a robot with a redundant degree of freedom with vision. The redundant robot with a degree of freedom has a horizontal moving guide rail, a large-load three-axis robot arranged on the horizontal moving guide rail, and a large-load three-axis robot connected in series with the large-load three-axis robot. The small-load six-axis robot, the 3D camera and the welding torch set at the end of the small-load six-axis robot. The invention increases the number of degrees of freedom of the robot, so that it can flexibly adapt to the welding of workpieces with complex shapes and large sizes, and eliminates the influence of horizontal moving guide rails and three-axis robots with large loads on absolute accuracy, and the welding quality only depends on The six-axis robot with small load has high welding accuracy; at the same time, intelligent welding is realized, and the workpiece welding can be completed without personnel participation.

Owner:南京衍构科技有限公司

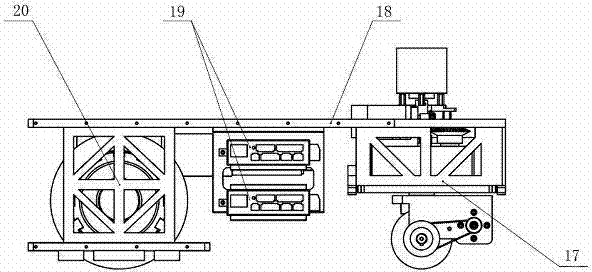

Autonomous mobile dithering hot wire tungsten-inert-gas (TIG) welding robot system for welding large-sized precision equipment

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile dithering hot wire tungsten-inert-gas (TIG) welding robot system for welding large-sized precision equipment. The system comprises a robot body, a control system and a dithering hot wire TIG welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; and the dithering hot wire TIG welding system comprises a dithering hot wire TIG welding gun, a dithering hot wire TIG welding power supply, a wire feeding machine, shielding gas and a weld cooling system. The system has the advantages that a contact type magnet-wheel adsorption and non-contact type clearance adsorption composite mode and a three-wheel full-drive wheel type movement mode are systematically used by the crawling mechanism, so that a robot can autonomously and flexibly move at all positions on the surface of a large-sized steel structure, can be reliably adsorbed and can perform dithering hot wire TIG all-position welding operation, and the system is high in comprehensive performance.

Owner:DONGFANG ELECTRIC CORP LTD

Automatic argon arc welding control system

InactiveCN107052532ARealize intelligent weldingOvercome the problem of not being able to automatically weld according to product outer diameter changesArc welding apparatusElectricityControl system

The invention discloses an automatic argon arc welding control system. A PLC is connected with a power supply and an HMI, the PLC is electrically connected to a servo motor firstly, then the servo motor is electrically connected to a product disc to form a product disc control circuit, the PLC, a relay and an electromagnetic valve are sequentially and electrically connected, then the electromagnetic valve is connected with a pressing air cylinder through a gas pipeline to form a product fixing control circuit, the PLC is electrically connected with a welding device and an automatic adjusting device, and the welding device and the automatic adjusting device are mechanically connected to form a control loop. The automatic argon arc welding control system is used for argon arc welding control over regular and irregular devices and suitable for welding positioning of irregular circular surfaces such as circular surfaces and oval surfaces, and can automatically adjust the welding position distance according to the position of the welding surface.

Owner:上乘精密科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com