Multi-station robot welding system based on welding seam intelligent identification technology for ring-disc parts

A robot welding and robot system technology, which is applied in the field of multi-station robot welding system for ring-disc parts, can solve the problems of large welding limitations, uneven weld width, and unfixed position, so as to improve welding efficiency and realize intelligent recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

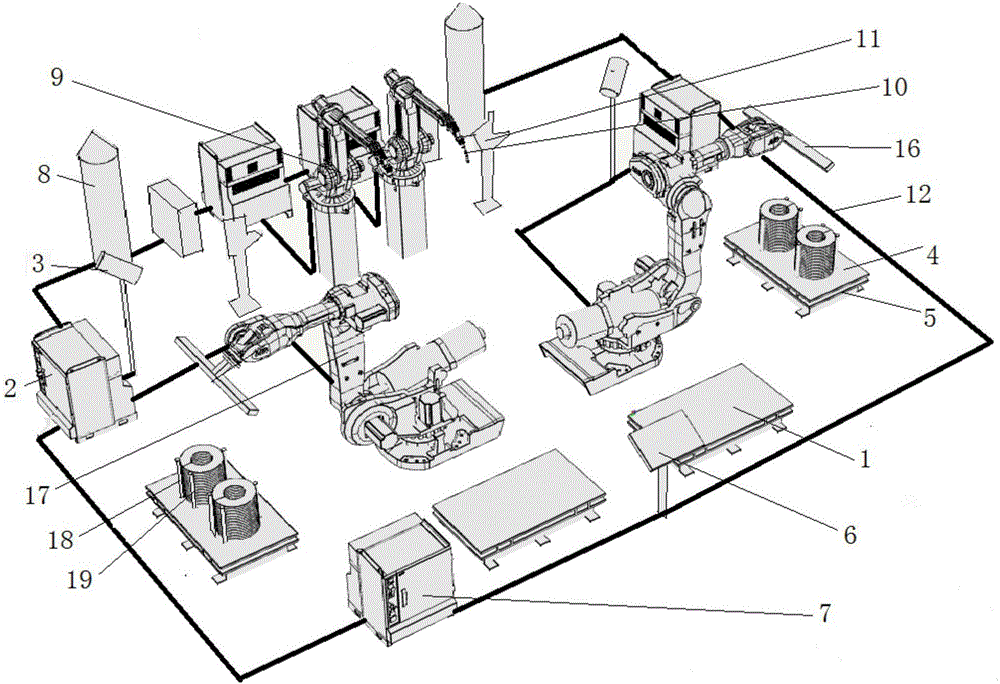

[0028] Accompanying drawing is a kind of specific embodiment of the present invention, the present invention will be further explained below in conjunction with specific embodiment:

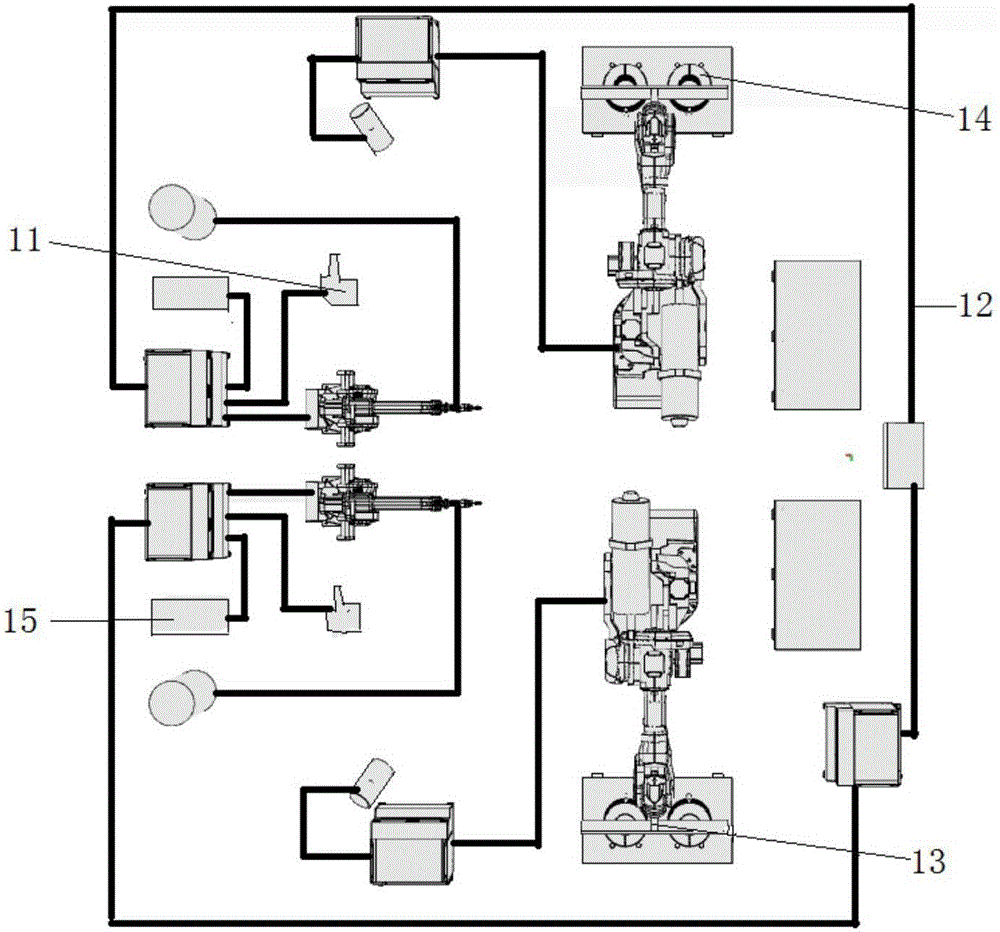

[0029] A multi-station robot welding system for ring-disk parts based on weld intelligent recognition technology includes a robot system, a control system, a fixture system, a machine vision system, a welding system and a safety protection system.

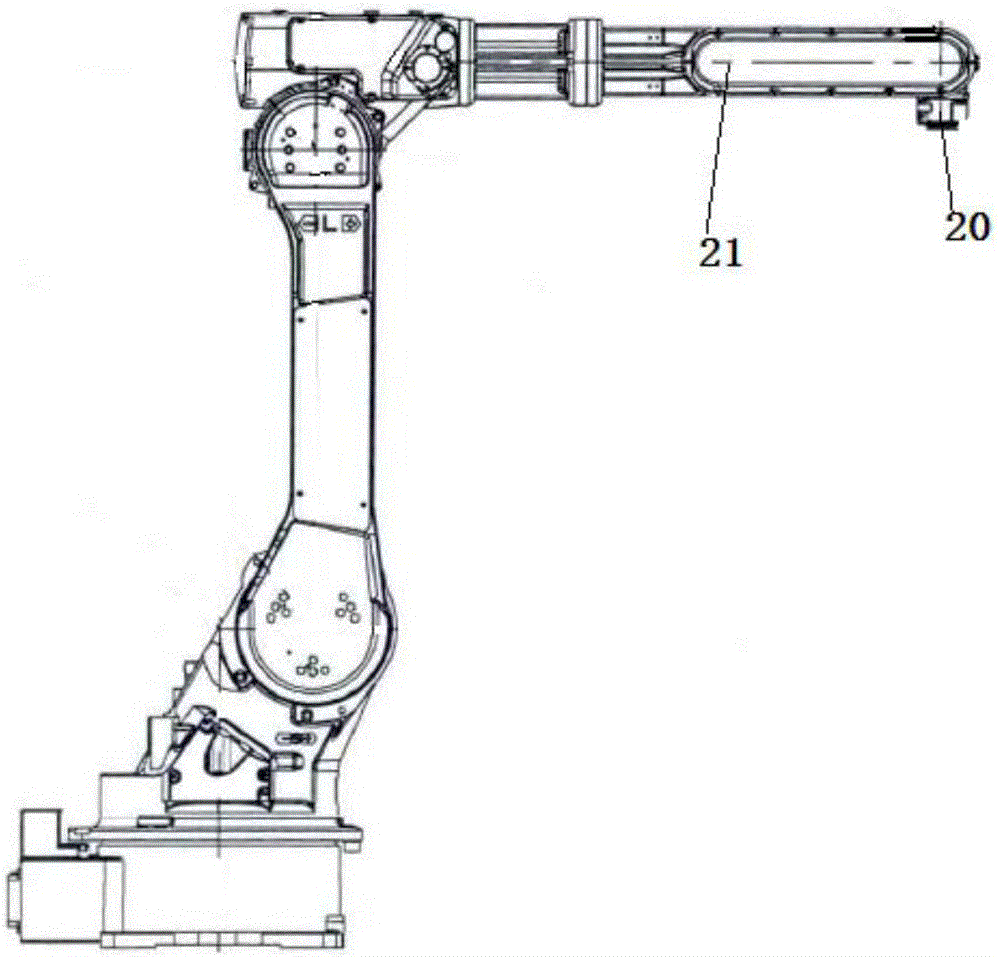

[0030] The robot system includes two feeding robots 17 and two welding robots 9. The structures and compositions of the four robots are basically the same, but the technical parameters are different; the two feeding robots 17 are placed on two finished product racks with their backs 1. On the front side, a feeding blank rack is placed under each feeding robot arm 21, and the feeding robot transports the ring-disk parts blanks to the front and bottom of the CCD sensor 3 and takes pictures before moving to the welding robot 9; the two welding The robots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com