Welding seam tracking method for pressing roller welding

A roller and tracking system technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low degree of intelligence, great human injury, and the straightness of the welding seam suppressing the roundness deviation of the roller 8

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

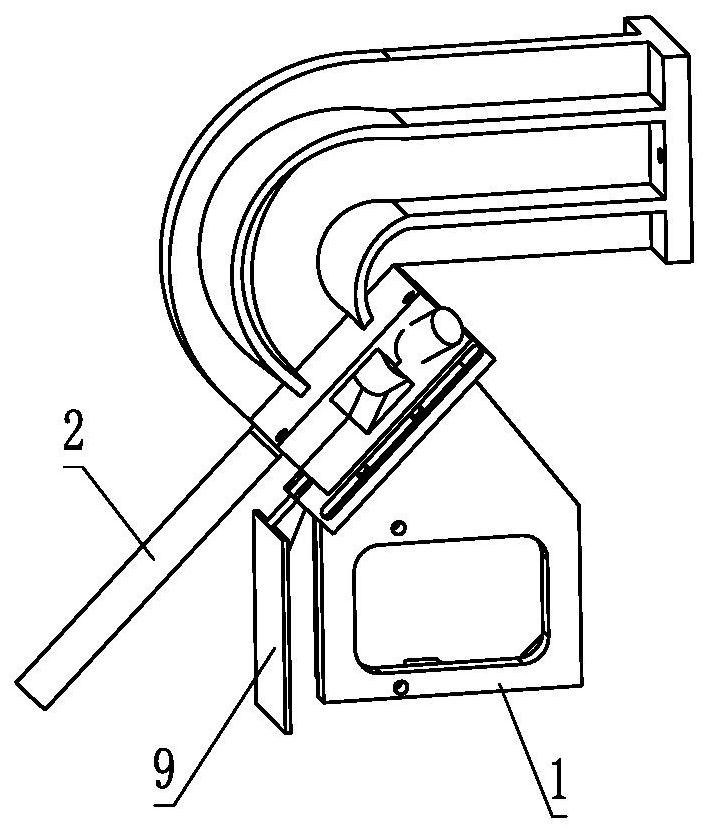

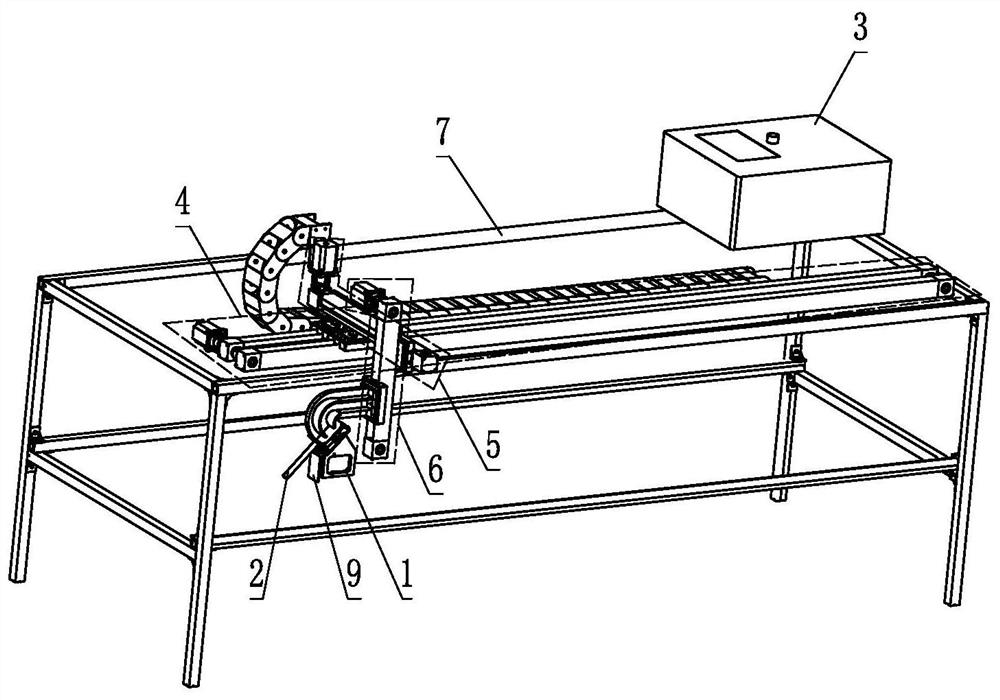

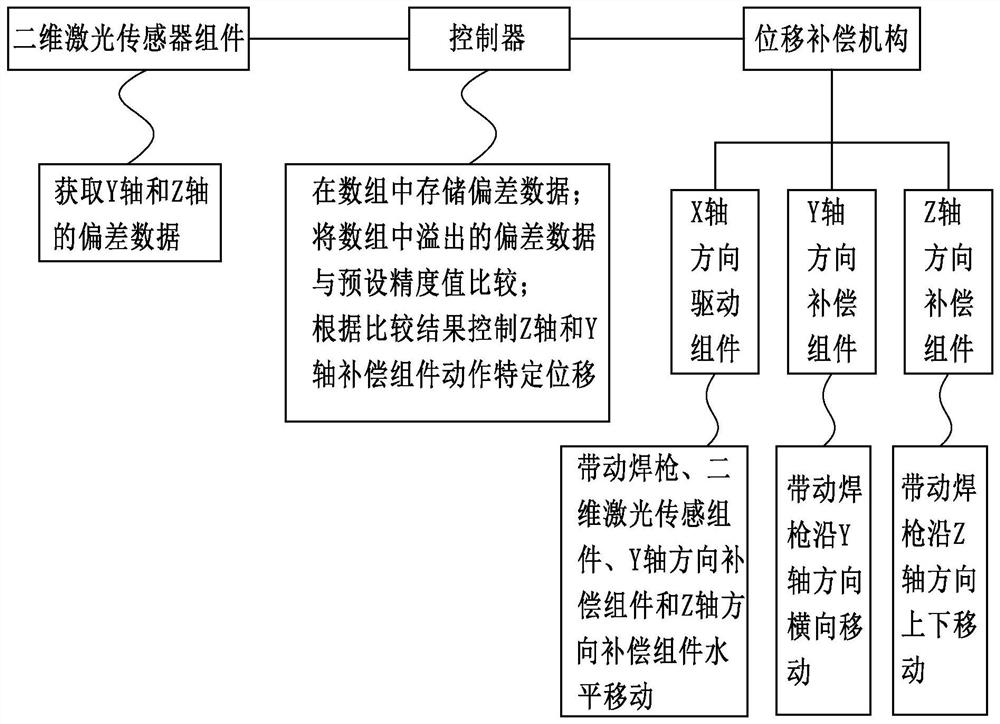

[0024] This embodiment provides a seam tracking method for pressure roller welding, the seam tracking method includes a seam tracking system based on a two-dimensional laser sensing component 1, and the seam tracking system includes a two-dimensional laser sensing component 1. Welding torch 2, displacement compensation mechanism and controller 3; the two-dimensional laser sensing component 1 and the welding torch 2 are both fixed on the connecting seat, and the two-dimensional laser sensing component 1 is located at the front end of the welding torch 2. In this embodiment, two-dimensional The value range of the distance D between the laser sensor assembly 1 and the welding torch 2 is between 15-20cm, see figure 1 , in this embodiment, in order to avoid the arc generated during the operation of the welding torch 2 from affecting the two-dimensional laser sensing assembly 1, it is preferable to provide a light shield 9 between the two-dimensional laser sensing assembly 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com