Automatic argon arc welding control system

A control system and argon arc welding technology, which is applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of non-adjustable welding diameter range and automatic welding, etc., and achieve self-adaptive function, simple welding control, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

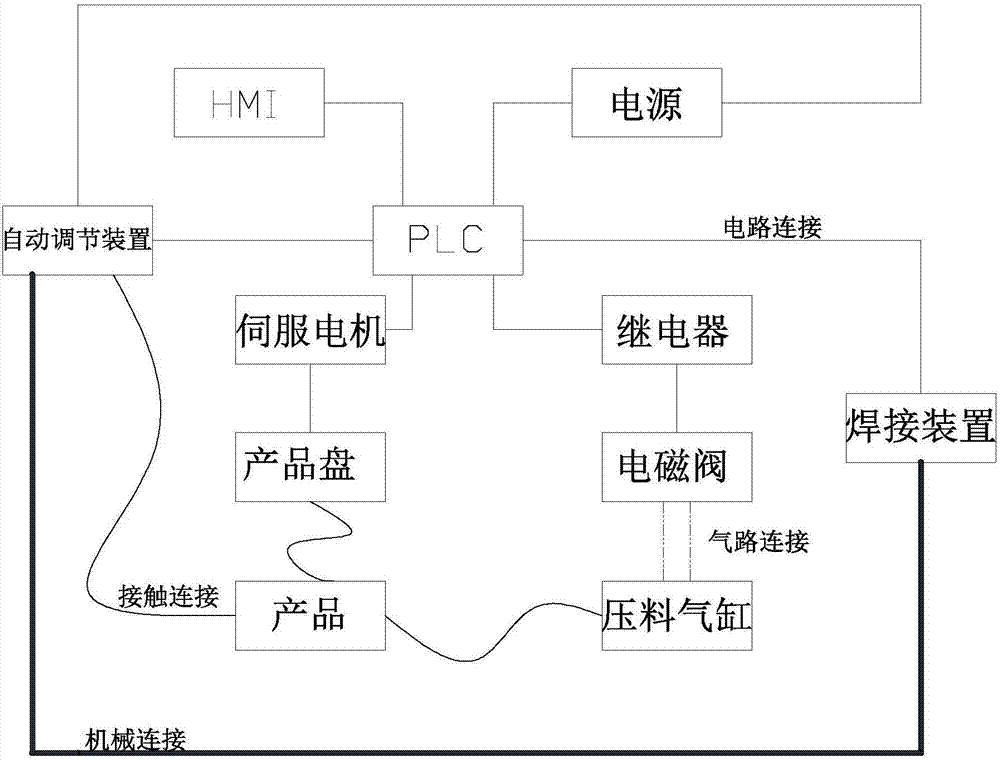

[0025] An automatic argon arc welding control system, such as figure 1 As shown, the PLC is connected to the power supply and HM. The PLC is first electrically connected to the servo motor, and then the servo motor is electrically connected to the product tray to form a product tray control circuit. The PLC, relay, and solenoid valve are connected in sequence, and then the solenoid valve is connected through the gas pipeline. The pressing cylinder forms a fixed control circuit for the product, the PLC is respectively connected to the welding device and the automatic adjustment device circuit, and the welding device is mechanically connected to the automatic adjustment device to form a control loop.

[0026] In the above, the automatic adjustment device is also connected to the power supply circuit. Specifically, the power supply includes multiple DC power supplies such as 5V DC power supply, the automatic adjustment device is connected to the 5V DC power supply circuit, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com