Autonomous mobile dithering hot wire tungsten-inert-gas (TIG) welding robot system for welding large-sized precision equipment

A robot system and precision equipment technology, applied in the field of autonomous mobile shaking hot wire TIG welding robot system, can solve the problems of incompatibility of motion flexibility and adsorption capacity, and meet the swing requirements, good system comprehensive performance, and flexible motion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

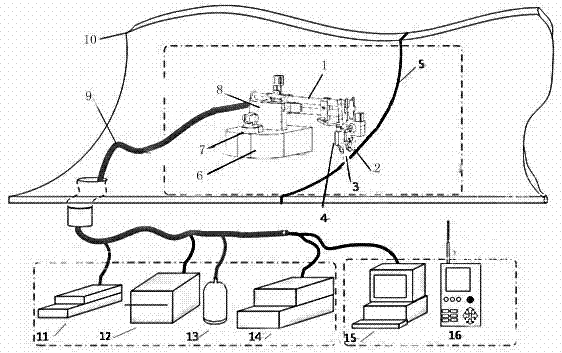

[0054] An autonomous mobile shaking hot wire TIG welding robot system for large precision equipment welding, including a robot body, a control system and a shaking hot wire TIG welding system, characterized in that:

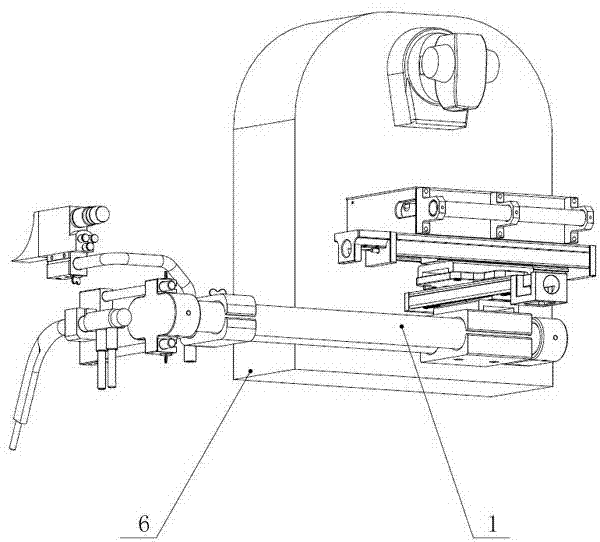

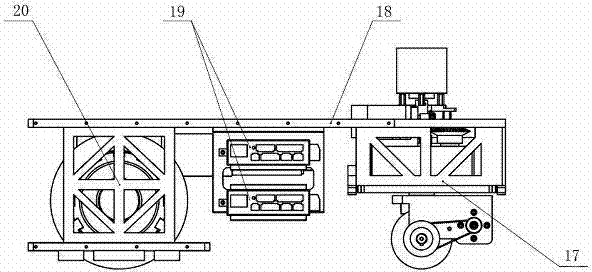

[0055] The robot body includes a crawling mechanism and an operating mechanism: the crawling mechanism includes a front wheel module using a drive-steering integrated magnetic wheel, a rear wheel module using a permanent magnetic gap adsorption device, a frame connecting the front and rear wheels, and a vehicle mounted on the frame. Motor drive controller; the operating mechanism includes a cross slider and a swing mechanism, the front end of the swing mechanism clamps the shaking hot wire TIG welding torch, and the degrees of freedom in the horizontal and vertical directions are combined by two screw guide rail combination units The cross slider is realized, and the swing mechanism adopts a stepping motor with a worm gear reducer;

[0056] The control system inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com