Robot welding technology parameter optimization method based on CBR and RBR

A technology for process parameter optimization and robot welding, applied in welding equipment, welding accessories, manipulators, etc., can solve problems such as a large number of experiments, unfavorable intelligent decision-making of welding processes by welding robots, and increase of welding process formulation time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

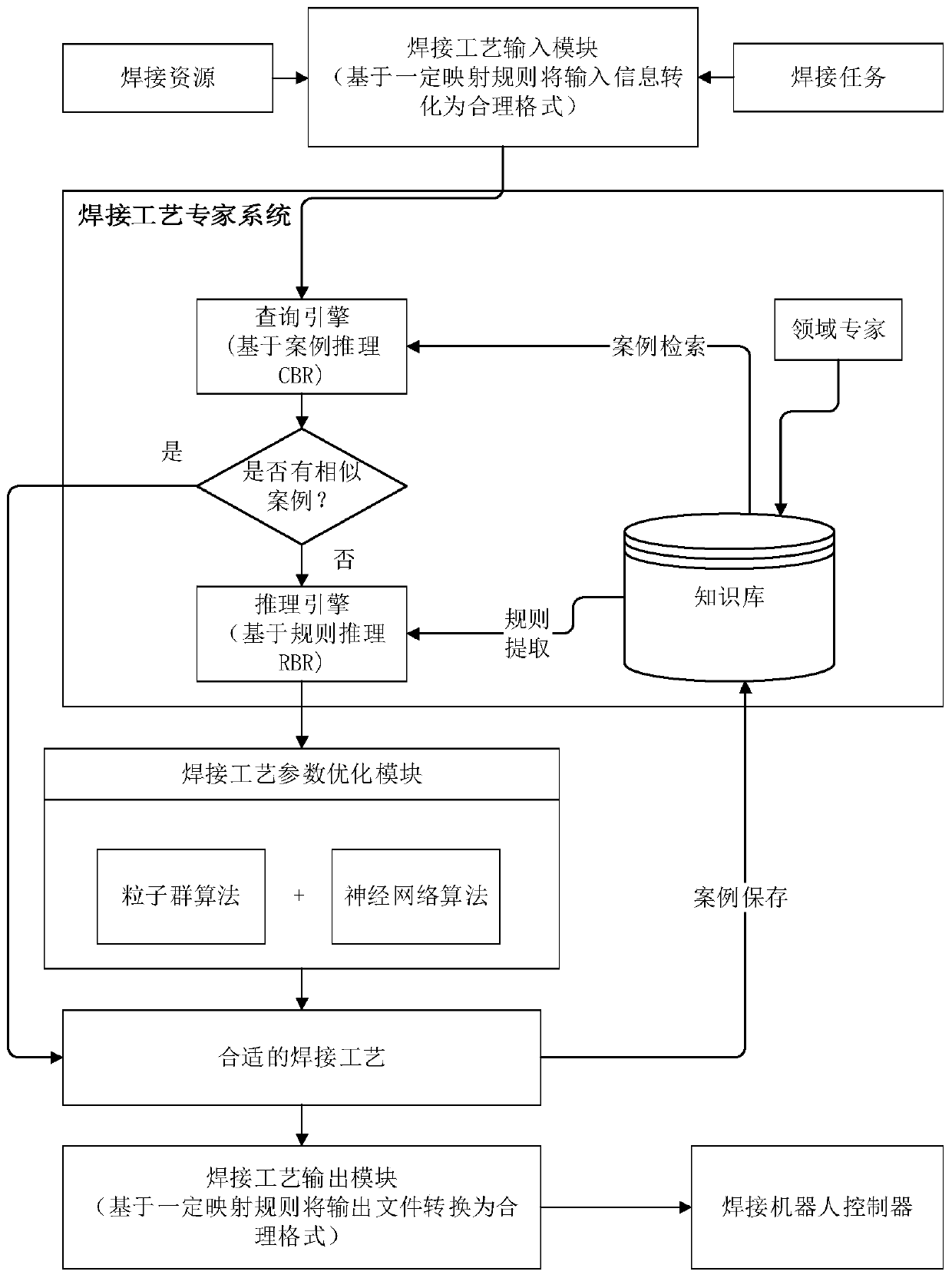

[0070] A method for optimizing robot welding process parameters based on CBR and RBR, including a welding process input module, a welding process expert system, and a welding process output module; figure 1 shown.

[0071] The welding process input module is used to convert the welding resource file and welding task file into an ontology language based on certain mapping rules, and then submit the welding information to the welding process expert system.

[0072]The welding process expert system is used to judge welding information and transfer corresponding welding processes; the welding process expert system includes a query engine, a reasoning engine, a knowledge base, and a welding process parameter optimization module, and the knowledge base includes a welding process case base and a welding process rule base, the query engine is used to judge whether the welding information belongs to a similar case in the welding process case base and imports the similar case into the ...

Embodiment 2

[0079] A kind of robot welding process parameter optimization method based on CBR and RBR as described in embodiment 1, its method is as described in embodiment 1, and concrete steps comprise:

[0080] (1) The welding process input module converts the welding resource file and welding task file into a reasonable format based on certain mapping rules and submits them to the welding process expert system;

[0081] (2) The query engine performs similar case query in the welding process case library. If a similar case is matched, the similar case is submitted to the welding process output module, and if there is no similar case, it enters the inference engine;

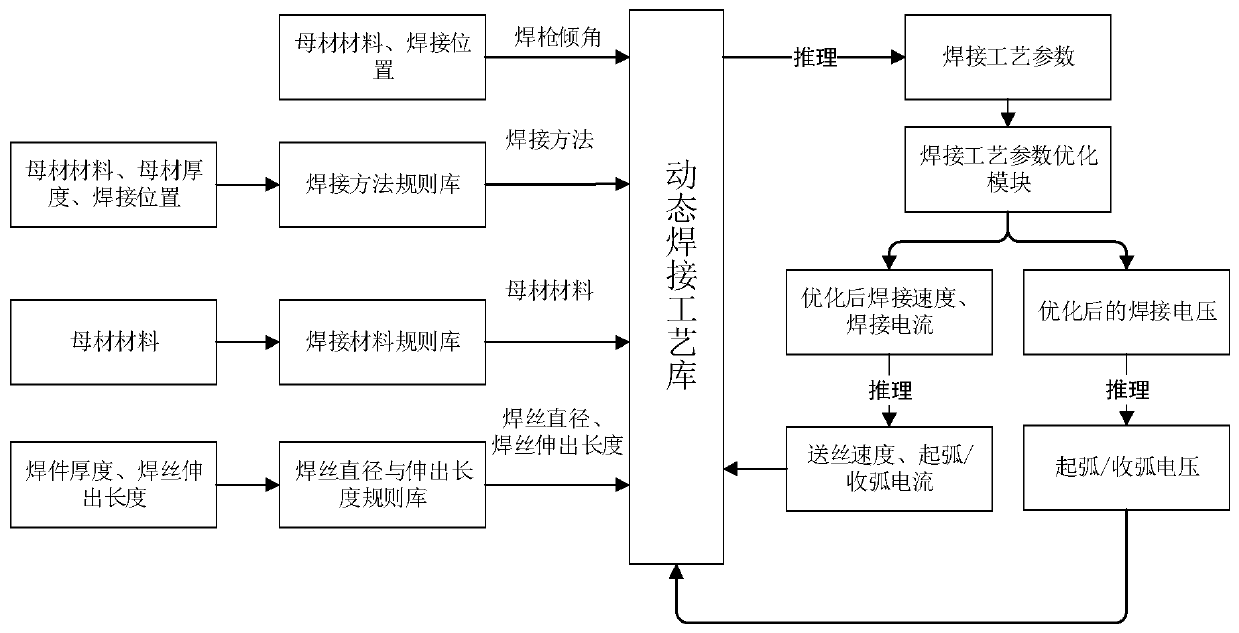

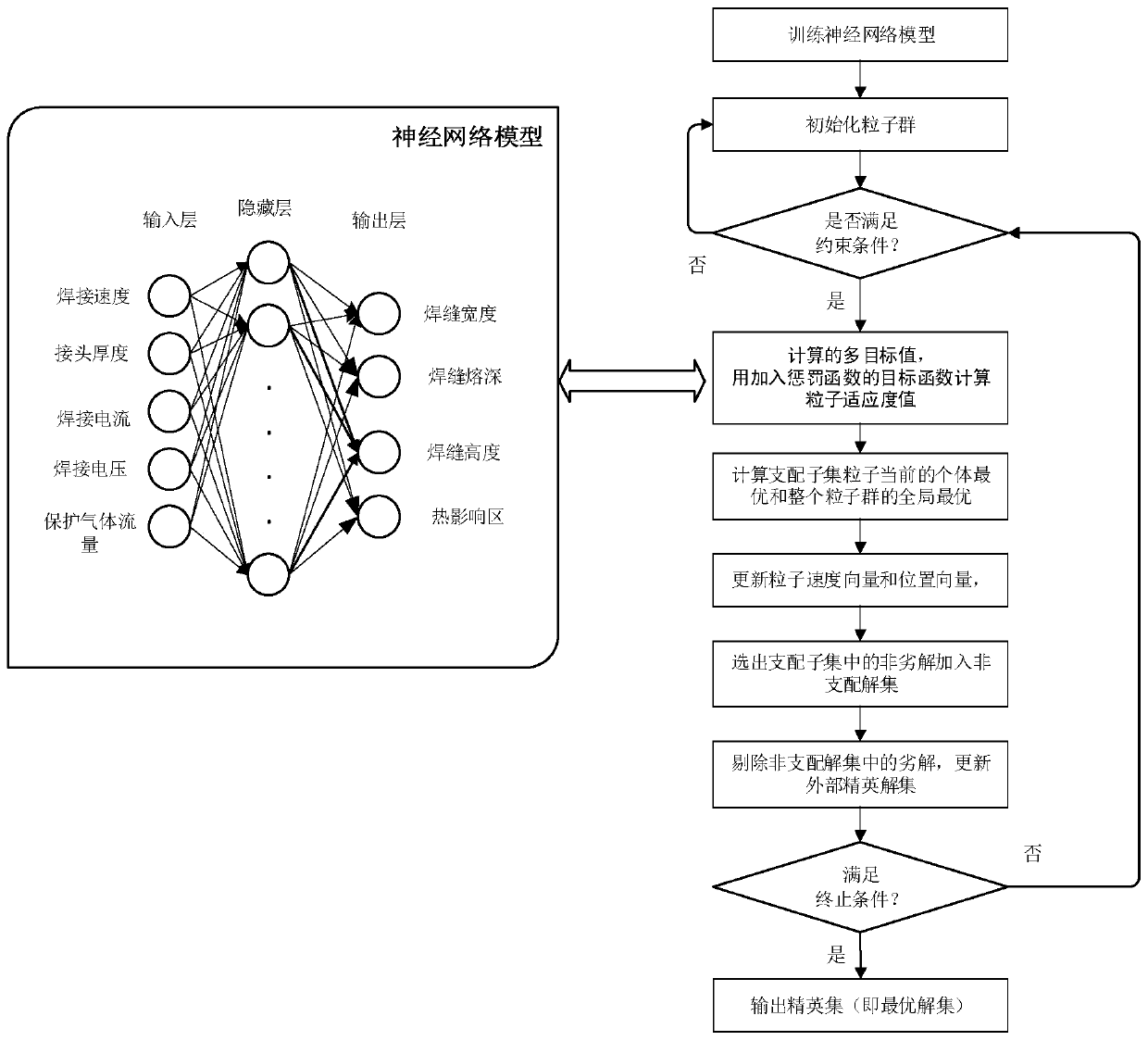

[0082] (3) The inference engine generates a suitable welding process after extracting the relevant rules in the welding process rule base; the welding speed, welding current, welding voltage, and shielding gas flow in the welding process obtained by the inference engine inference are suitable range values, which need Perfo...

Embodiment 3

[0087] A method for optimizing robot welding process parameters based on CBR and RBR as described in embodiment 1, its steps are as described in embodiment 2, further, in step (2), the query engine is composed of case-based reasoning (CBR ) mechanism, by analyzing and extracting the welding condition information in the welding task file, searching for similar cases in the welding process case library, and selecting the most matching welding process case according to the degree of similarity; specifically, when a new welding task appears, First, data preprocessing is performed on the welding condition information and represented by the problem feature vector X:

[0088] X=(x 1 ,x 2 ,x 3 ,x 4 ,x 5 ) (1)

[0089] where x 1 ,x 2 ,x 3 ,x 4 ,x 5 They are welding position, base metal material, base metal thickness, joint thickness and joint form;

[0090] The data preprocessing is to perform normalization processing on the base metal thickness and joint thickness whose dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com