Automatic argon arc welding device

A technology of argon arc welding and argon arc welding, which is applied in the field of automatic argon arc welding devices, can solve the problems of non-adjustable welding diameter range and inability to realize automatic welding, and achieve the advantages of increased self-adaptive function, good insulation and high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

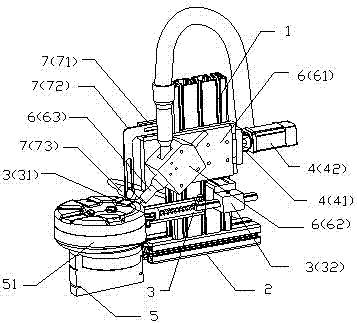

[0021] An automatic argon arc welding device, such as figure 1 As shown, the vertical support 2 is vertically connected to the horizontal support 1, the welding torch traverse device 4 is connected to the vertical support 2 through the traverse groove 41 thereon, and the moving rod inside the traverse groove 41 is connected to the motor 42, The fixed plate 61 is connected with the moving rod, and the welding torch head fixing frame 62 is connected to one end of the fixing plate 61, and the welding torch head fixing frame 62 is fixed with an argon arc welding torch head 63, and a connection is provided on the upper part of the fixing plate 61 near the argon arc welding torch head 63. 71, connecting piece 71 is connected with wire feeding head 73 through adjusting piece 72, one end away from described argon arc torch head 63 at the bottom of fixing plate 61, automatic adjustment device 3 is connected with fixing plate 61 through fixing bracket 32 at one end.

[0022] The autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com