Intelligent multi-welding-head ultrasonic welding machine

An ultrasonic welding and multi-welding head technology, which is applied to household components, household appliances, and other household appliances, can solve problems such as low precision, large welding gaps, and poor welding quality, and achieve reduced vibration, simple equipment structure, and easy to use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

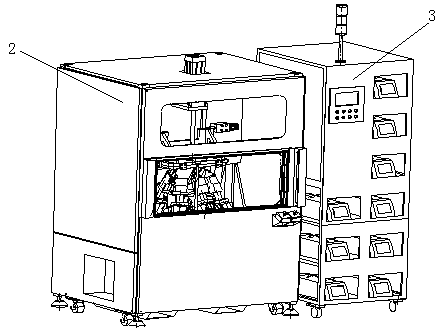

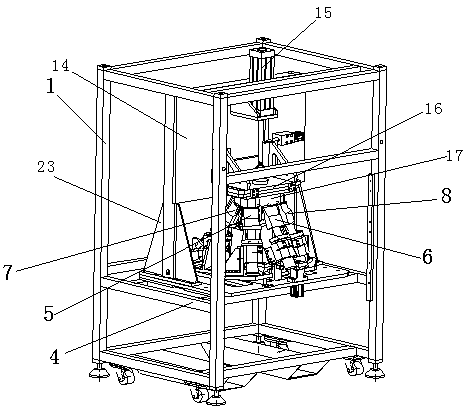

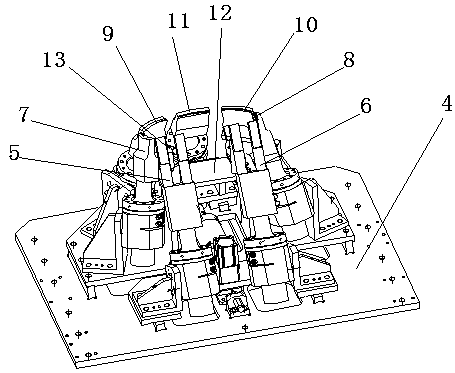

[0015] Such as figure 1 -4 shows: an intelligent multi-welding head ultrasonic welding machine, including a frame 1, an outer cover 2 and an electrical control cabinet 3 connected to the outside of the frame 1, and the welding unit set in the frame 1 is a multi-welding head welding group And the workpiece positioning device that drives the workpiece to press down and weld. The multi-welding head welding group is arranged on the base connecting plate 4 in a ring shape. The multi-welding head welding group is composed of 7 groups of welding units, further including the left front welding head 5, the right front welding head 6, The left side welding head 7, the right side welding head 8, the rear left side welding head 9, the rear right side welding head 10 and the rear middle welding head 11, 2 workpiece blowers are set on the middle seat 12 surrounded by the welding unit. Cold air outlet 13, the welding points of described left side welding head 7, right side welding head 8, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com