A control system for an automatic adjustment device of an argon arc welding machine

An automatic adjustment and device control technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problem of non-adjustable welding diameter range, achieve the effect of increasing self-adaptive function and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

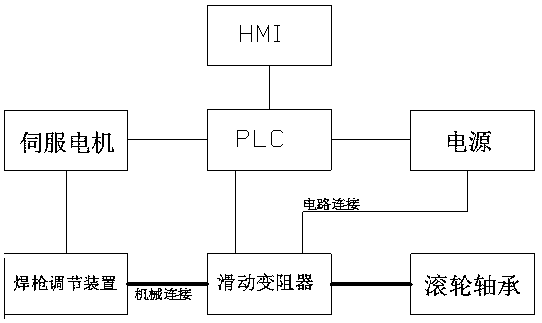

[0019] A control system for an automatic adjustment device of an argon arc welding machine, such as figure 1 As shown, the HMI is connected to the PLC circuit, and the PLC circuit is connected to the servo motor, and the servo motor is connected to the welding torch adjustment device to form a control circuit, and the PLC, sliding rheostat and power supply are connected in pairs to form an acquisition circuit.

[0020] In the above, the sliding rheostat is also mechanically connected with a roller bearing, which rolls on the welding surface of the product, collects the information of the welding surface in real time, and transmits the diameter and shape information of the welding surface to the sliding rheostat.

[0021] In this control system, the control line is regulated according to the position information collected by the collection line, and the data is processed by the PLC, while the HMI directly visualizes the position information collected by the PLC, and the HMI prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com