Intelligent welding control system and method for thick-plate narrow-gap GMA robot

A control system and robot technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve the effect of facilitating welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

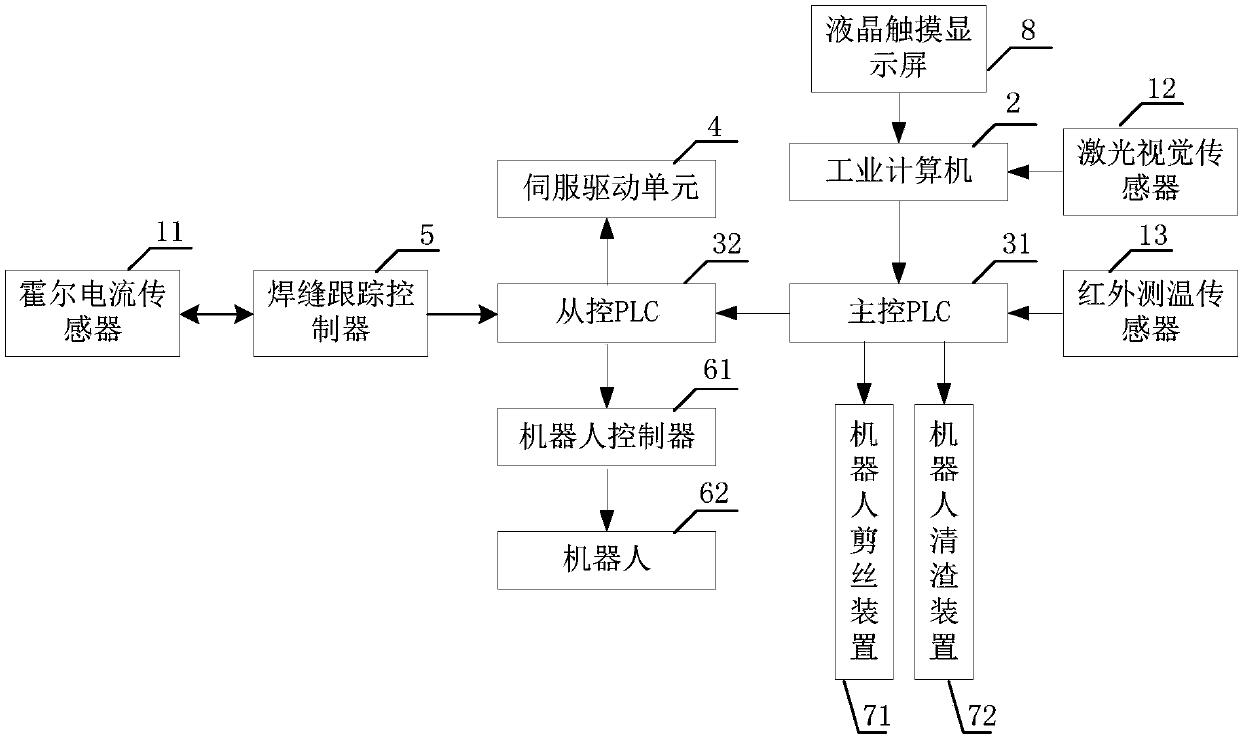

[0046] Specific implementation mode one: refer to figure 1This embodiment is described in detail. The intelligent welding control system for thick plate narrow gap GMA robot described in this embodiment includes a Hall current sensor 11, a laser vision sensor 12, an infrared temperature sensor 13, an industrial computer 2, a main control PLC31, slave PLC32, seam tracking controller 5 and LCD touch screen 8.

[0047] The Hall current sensor 11, the laser vision sensor 12 and the infrared temperature sensor 13 constitute the multi-source information sensing part of the intelligent welding control system, and the main sensing functions are as follows:

[0048] The Hall current sensor 11 is used to collect the average value of the current in the stable state of welding, and the average value of the current is the average value of the current at the left and right sides of the stop position and the center position of the groove in each arc movement cycle; the laser vision sensor 12...

specific Embodiment approach 2

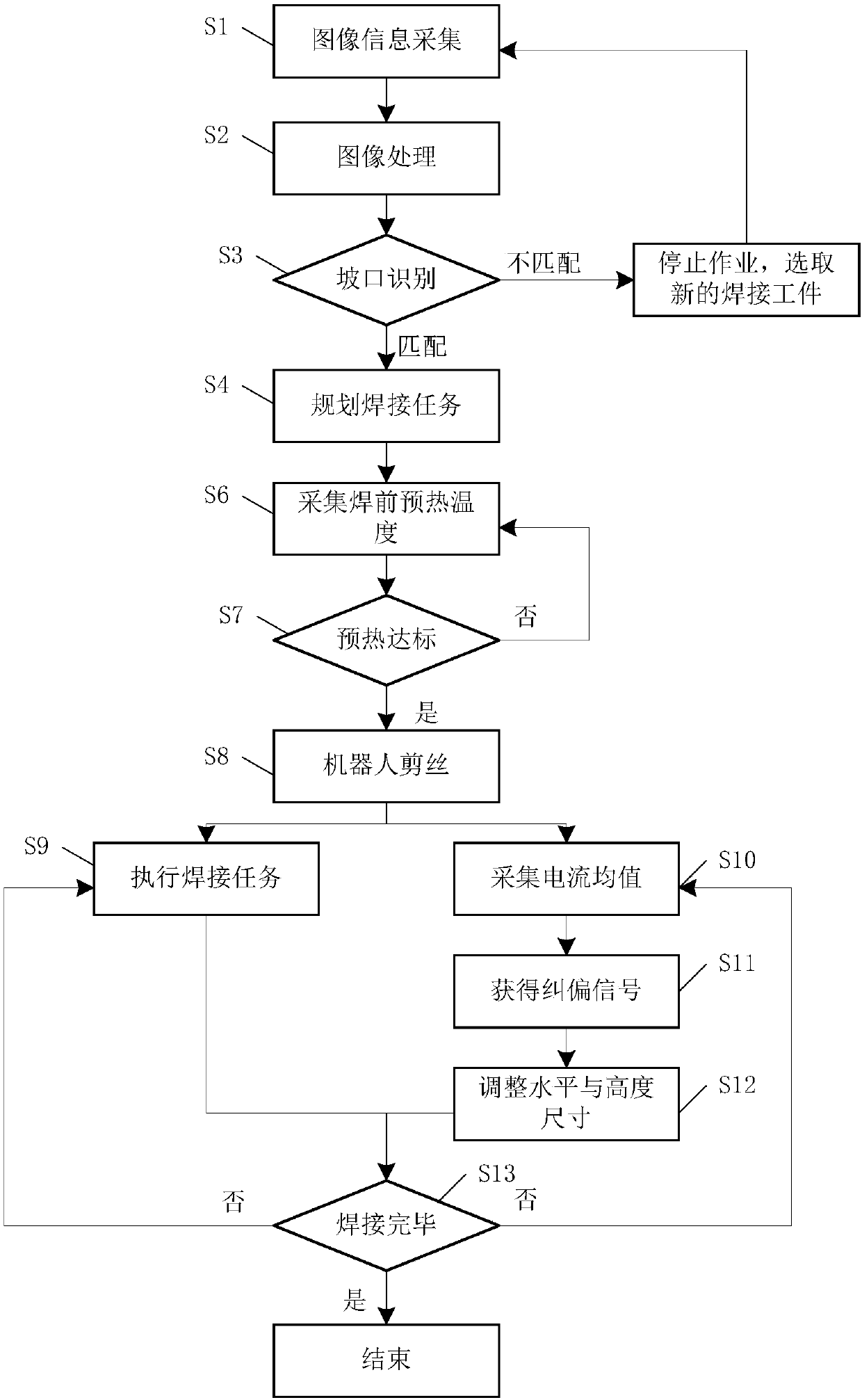

[0064] Specific implementation mode two: refer to figure 2 Specifically explain this embodiment, the intelligent welding control system for thick plate narrow gap GMA robot according to claim 1 described in this embodiment, the intelligent welding control method for thick plate narrow gap GMA robot, comprising the following steps :

[0065] S1: collect the thickness of the workpiece to be welded, the groove form, the workpiece material and the groove image of the workpiece to be welded,

[0066] S2: Perform image noise reduction, binarization, inflection point recognition and smoothing processing on the groove image in sequence to obtain the groove width, welding start point position and welding end point position of the workpiece to be welded,

[0067] S3: Match the groove width of the workpiece to be welded with the standard workpiece model library, if it matches, execute S4, if not, execute S5,

[0068] S4: Determine the number of welding layers, welding specifications a...

specific Embodiment

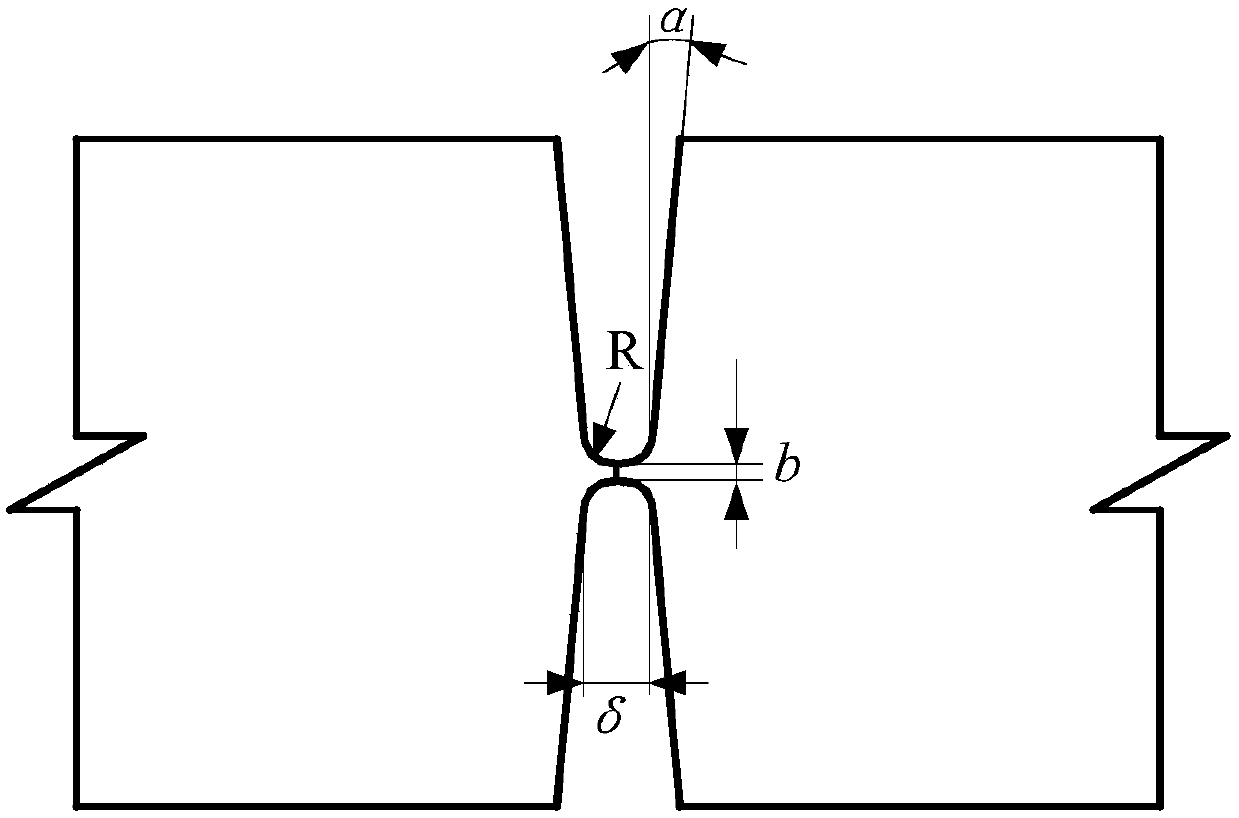

[0080] Jack-up platforms (such as wind power installation ships, riprap leveling ships, and oil and gas drilling platforms, etc.) are mainstream marine engineering equipment for offshore resource exploration and exploitation. The key is to stabilize the legs of the platform, and its structural design and manufacturing directly affect To the service safety and use effect of the platform. As the core load-bearing part of the pile leg, the rack not only bears the weight of the platform itself, but also withstands the erosion and damage caused by harsh sea conditions such as wind, waves, currents, drift ice, and marine earthquakes. At present, the rack steel is generally used in the world. Extra-thick special steel for advanced quenching and tempering heat treatment strengthening with a yield strength of 690MPa or more and a thickness specification of 120mm or more (see Table 1). Due to the construction characteristics of large scale, ultra-thickness, high strength, high toughness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com