Double-torch pipeline full-position automatic welding machine

An automatic welding machine and all-position technology, which is applied in mechanical equipment, pipeline systems, welding equipment, etc., can solve problems such as difficult to achieve optimal welding quality, easy fatigue, and welding defects, and achieve system maintenance and expansion capabilities. Line Cable simplification and the effect of improving the quality of welding molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

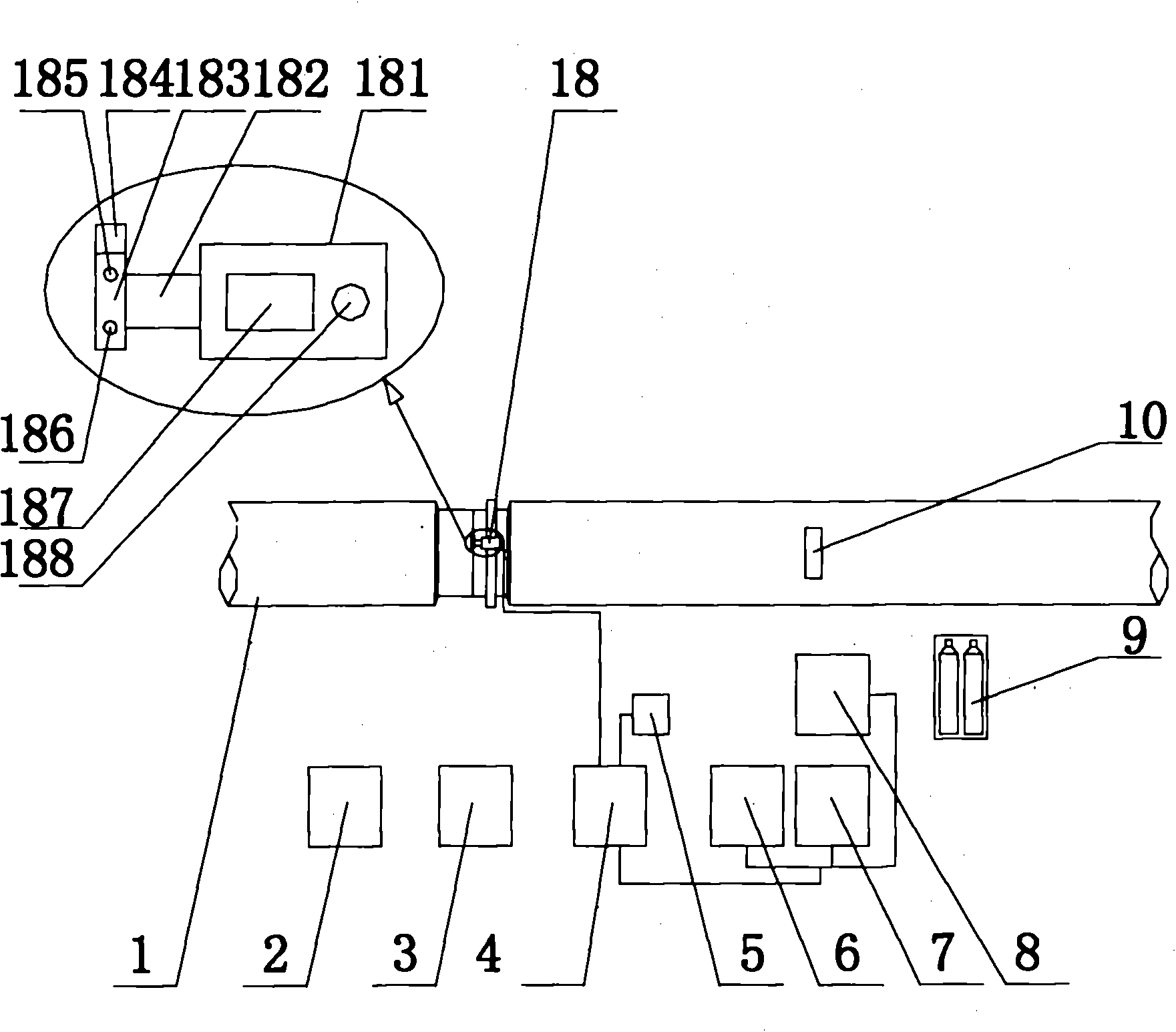

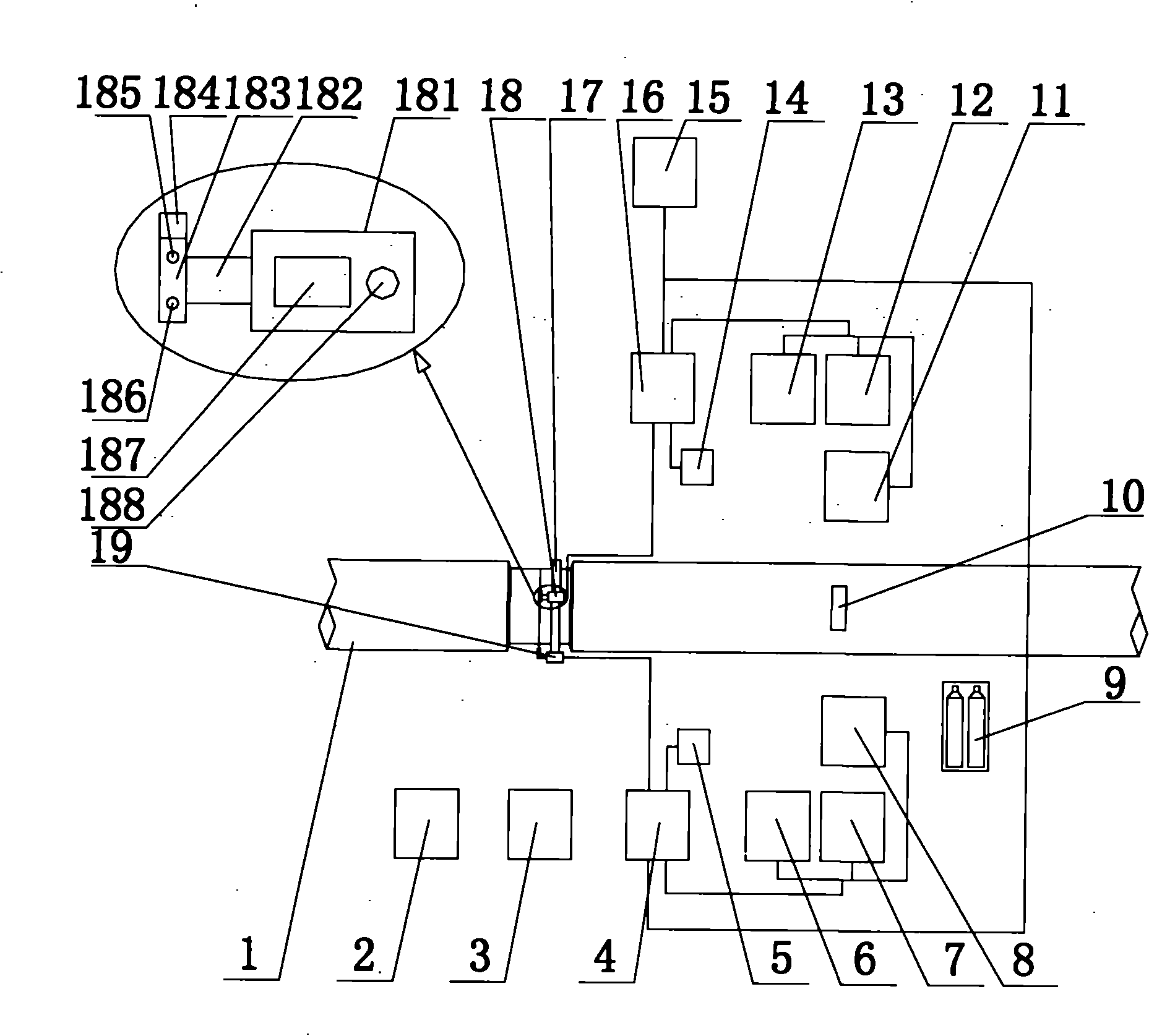

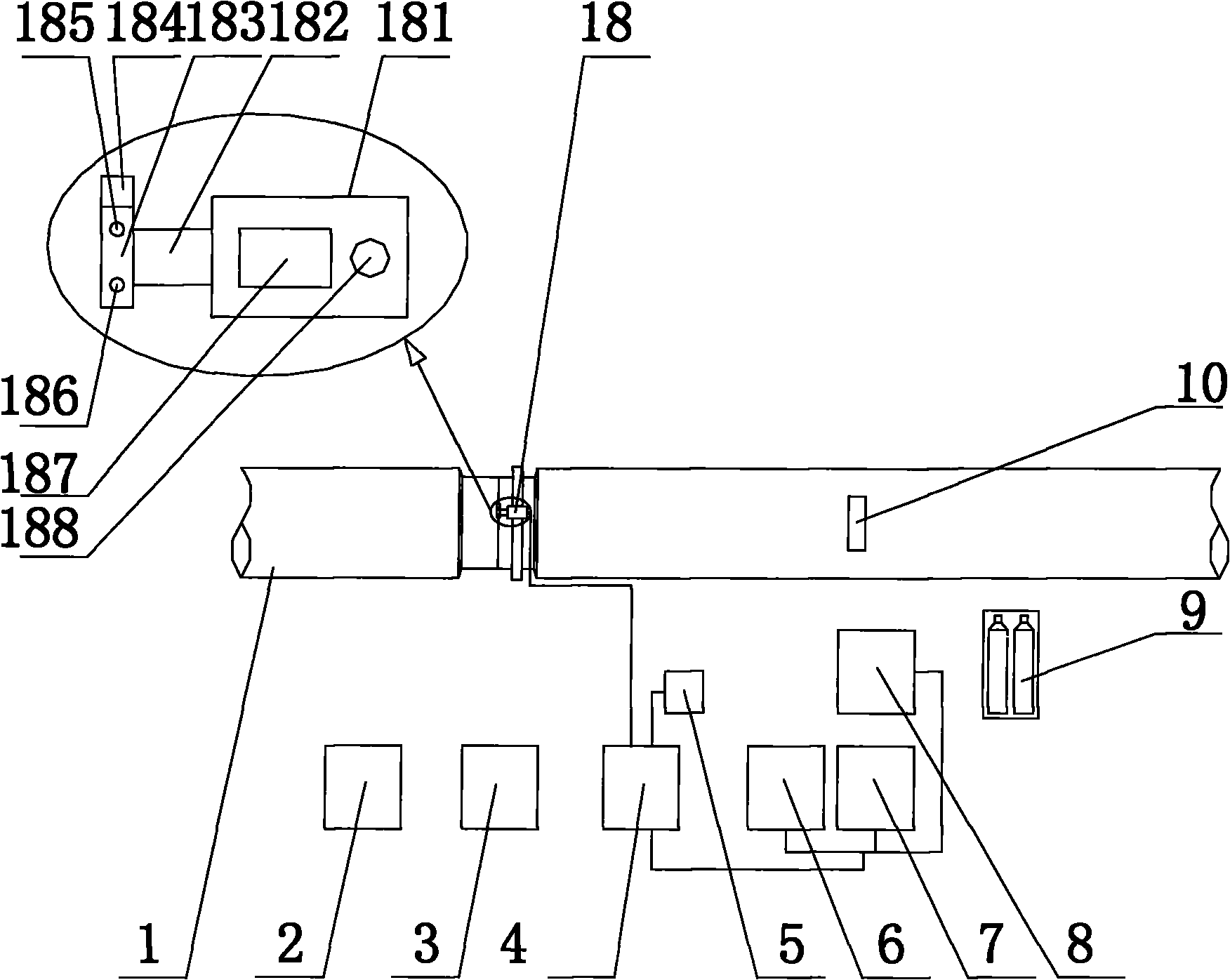

[0024] Such as figure 1 As shown, the present invention comprises: the welding trolley 18 that is installed on the guide rail, welding control box 4, wire feeding box 8, welding power source 6,7 and manual control box 5; 182 controls two welding torches 185, 186 and a height adjustment mechanism 183; the welding control box 4 is provided with a controller composed of a PLC programmable controller, a single-chip microcomputer or a digital signal processor (DSP) chip; on the welding trolley 18 A laser tracking probe 14 and a sensor 188 are installed, and the laser tracking probe 14 and the sensor 188 are connected to the controller in the welding control box 4 respectively, and the controller is connected to the remote monitoring computer 15 through a network. In this embodiment: the sensor 188 is an inclination sensor, the inclination sensor 188 is connected to the input terminal of the motor driver 187 of the traveling mechanism 181 through the I / O input interface, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com