Universal chuck of numerical control tool grinding machine

A tool grinder and chuck technology, which is applied in the field of universal chucks of CNC tool grinders, can solve the problems of easy displacement during processing and difficult clamping of spherical aluminum parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

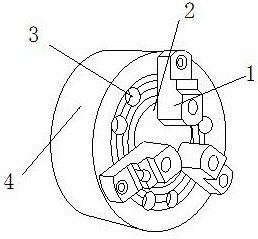

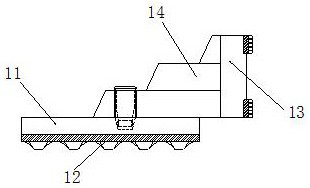

[0025] as attached figure 1 to attach Figure 4 Shown:

[0026] The present invention provides a universal chuck for a CNC tool grinder, the structure of which includes a clamping tooth 1, a clamping opening 2, a threaded opening 3, and a chuck 4. The locking teeth 1 are inlaid on the inner end surface of the chuck 4 and are evenly distributed. , the clamping port 2 is located at the transverse center of the chuck 4, and the threaded port 3 is uniformly installed on the outer end face of the chuck 4; Trapezoidal block 14, the trapezoidal block 14 is fixedly installed on the upper end surface of the embedded solid bar 11, the inlaid tooth 12 is embedded and fitted directly below the embedded solid bar 11, and the left end surface of the fixed plate 13 is installed on the trapezoidal shaped block by welding. On the right side of the block 14 , the trapezoidal block 14 is inlaid directly above the mosaic teeth 12 .

[0027] Wherein, the fixed plate 13 includes a helical tooth ...

Embodiment 2

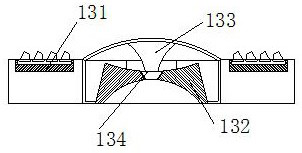

[0032] as attached Figure 5 to attach Figure 7 As shown: the squeeze ball 34 includes a second air port 341, a rubber ball 342, an arc block 343, and an air valve 344, and the second air port 341 is evenly distributed on the inner surface of the upper end of the rubber ball 342, and the rubber ball 342 is embedded and installed directly above the outer side of the arc-shaped block 343. The arc-shaped block 343 is embedded and installed on the inner upper end surface of the extrusion ball 34. The air valve 344 is symmetrically arranged on the inner surface of the lower end of the extrusion ball 34. The installation position of the air valve 344 is just at the dead angle of the second air port 341 and cannot be overlapped, which can effectively ensure that there is still air on the connecting end faces of the two after extrusion.

[0033] Wherein, the air valve 344 includes an embedding block 441, a seepage mechanism 442, a one-way port 443, and a rubber sheet 444. Located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com