Composite drill bit

A technology of mixing drill bit and bit body, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc., which can solve the problems of low rock breaking efficiency, low rock efficiency, low energy utilization rate, etc., and achieve improved rock breaking efficiency and rock breaking efficiency Improve and benefit the effect of rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

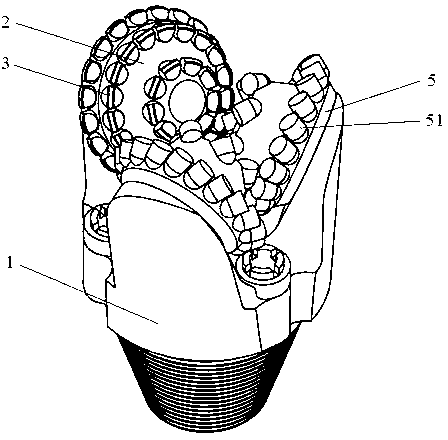

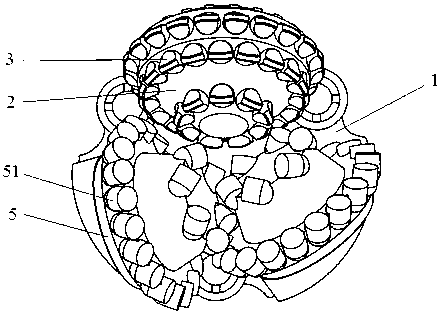

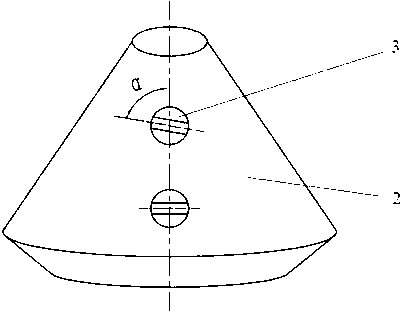

[0098] Embodiment 1: as Figures 1 to 4 As shown, a hybrid drill bit includes a drill body 1, at least one cone 2 and at least one disc cutter 5, the cone 2 and the disc cutter 5 form a rotational connection with the drill body 1 through a bearing structure respectively, and the offset of the disc cutter 5 The range of the angle is [20°, 90°] or [-90°, -20°], the disc cutter 5 is provided with a disc cutter cutting tooth 51, the tooth wheel 2 is provided with a transverse insert 3, and the transverse insert 3 The value range of the addendum deflection angle α is 70°≤|α|≤90°. Preferably, the transverse insert 3 can be cemented carbide teeth, cemented carbide teeth reinforced with diamond, impregnated diamond teeth, or thermally stable polycrystalline diamond teeth. like figure 1 , 2 Shown in the figure, a roller cone and two disc cutters are set on the hybrid drill bit.

Embodiment 2

[0099] Embodiment 2: as Figures 5 to 8 As shown, this embodiment is basically the same as Embodiment 1, the difference is that: the drill body 1 is also provided with a fixed cutting structure 4 including fixed cutting teeth 41 . like Figures 5 to 7 As shown in the figure, the hybrid drill bit is provided with two fixed-wing fixed cutting structures, one cone, and one disc cutter, and the two fixed wings are arranged alternately with the cone and disc cutter. like Figure 8 As shown, the hybrid drill bit is provided with three fixed-wing fixed cutting structures and one cone, two disc cutters, and three fixed wings, cones, and disc cutters are arranged alternately.

Embodiment 3

[0100] Embodiment 3: This embodiment is basically the same as Embodiment 1 or 2, the difference being that the 4-point addendum width of the horizontal insert 3 is not less than 80% of the transverse length L1 of the horizontal insert 3 . More preferably, the width of the four-point tooth top of the horizontal insert 3 is equal to the transverse length of the horizontal insert 3, such as Figures 14 to 25 shown. That is, the 4-point width W of the tooth top of the horizontal insert is equal to the maximum lateral dimension of the part below the 4-point tooth top area, or the 4-point tooth top width W of the horizontal insert is greater than the lateral maximum dimension of the part below the 4-point tooth top area , At this time, a mushroom-like shape with a large top and a small bottom is formed. Figure 17 , 18 , 23, and 24 are a kind of mushroom-shaped horizontal insert 3 of the present invention. The lower fixed part 31 of the horizontal insert 3 and the upper exposed pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com