Manufacturing method of implant tooth guide plate and guide plate manufactured by adopting method

A manufacturing method and technology for dental implants, which are applied in the fields of dental implants, dentistry, and dental prostheses, can solve the problems of removing too many bones, increasing patient trauma, and increasing the number of operations, so as to solve the positioning of dental implants and reduce postoperative pain. Discomfort and the effect of shortening the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. And the structure involved in this application or the technical terms used will be further explained below, unless otherwise specified, it will be understood and interpreted according to the general affiliation in this field.

[0041] Digital implant guides are divided into three categories: dental support guides, mucosal support guides and bone support guides. At the same time, according to the degree of tooth loss in the patient's mouth, these three guides can be further combined, namely dental support-mucosal support guides , Tooth support-bone support guide plate, mucosal support-bone support guide plate.

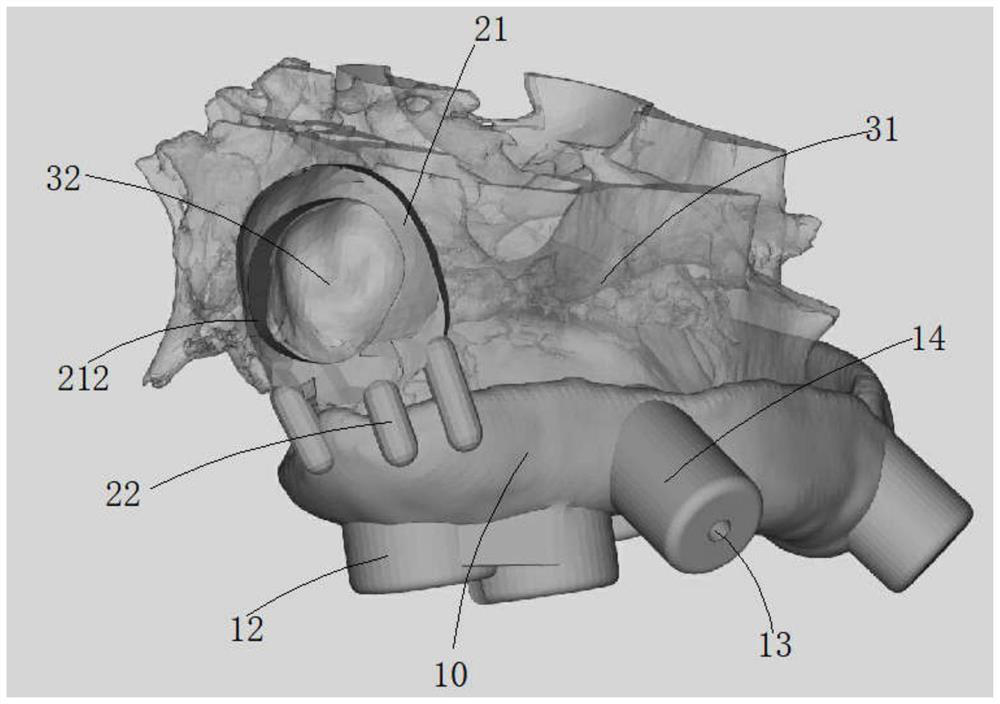

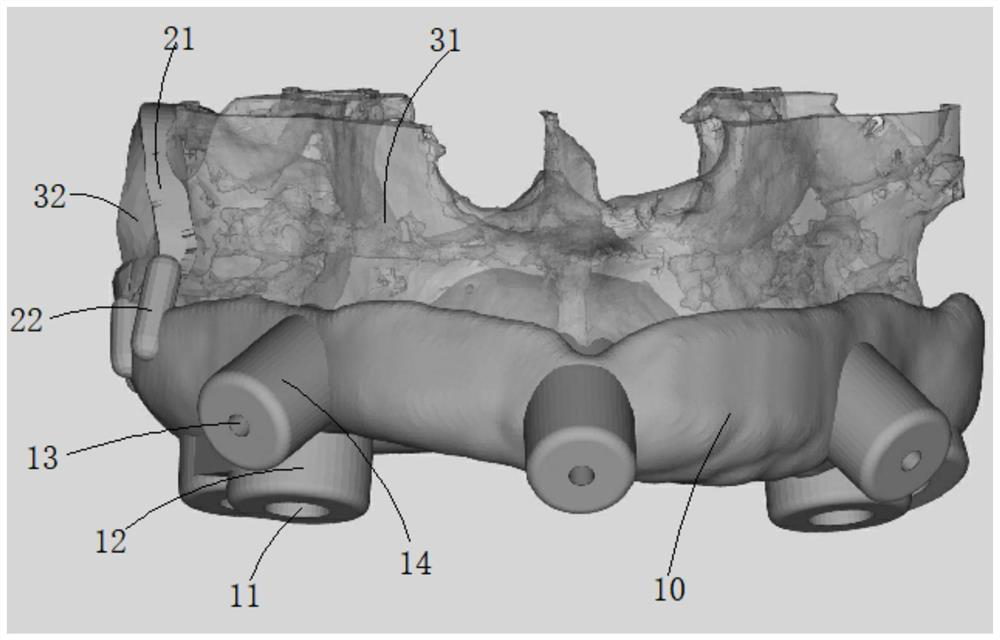

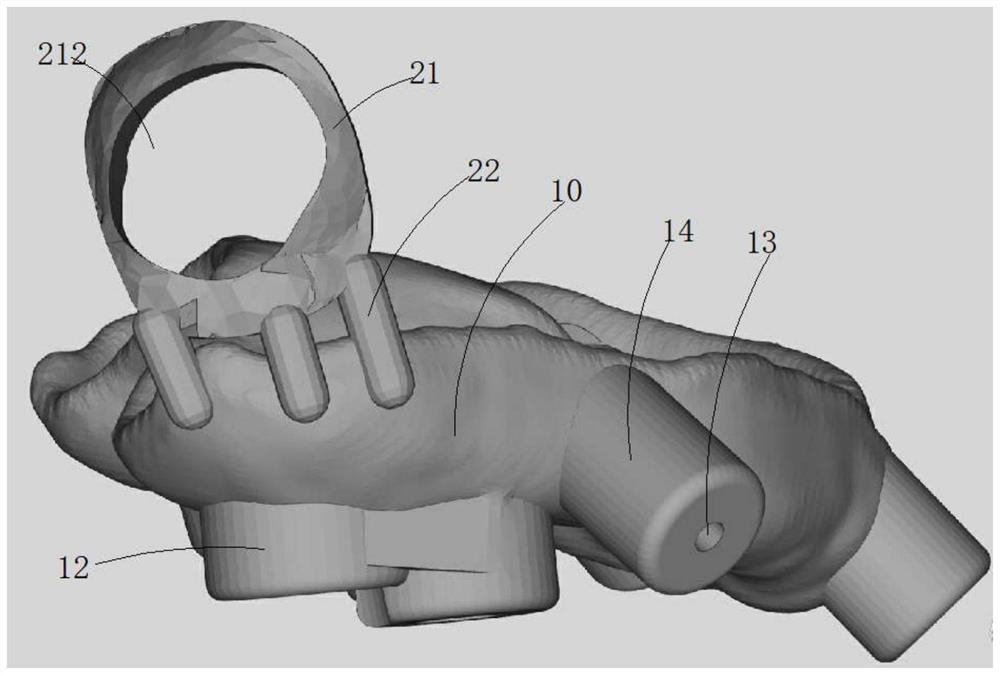

[0042] like Figure 1-7 As shown, a dental implant guide plate wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com