Fastener device for connecting and detaching bore rod

A clamping device and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of reducing cost, simplifying operation, reducing drilling rig space, compact structure, and can only be used for flanged drill pipe, etc. , to achieve the effects of easy automatic operation, optimized removal of obstacles, and good mechanical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

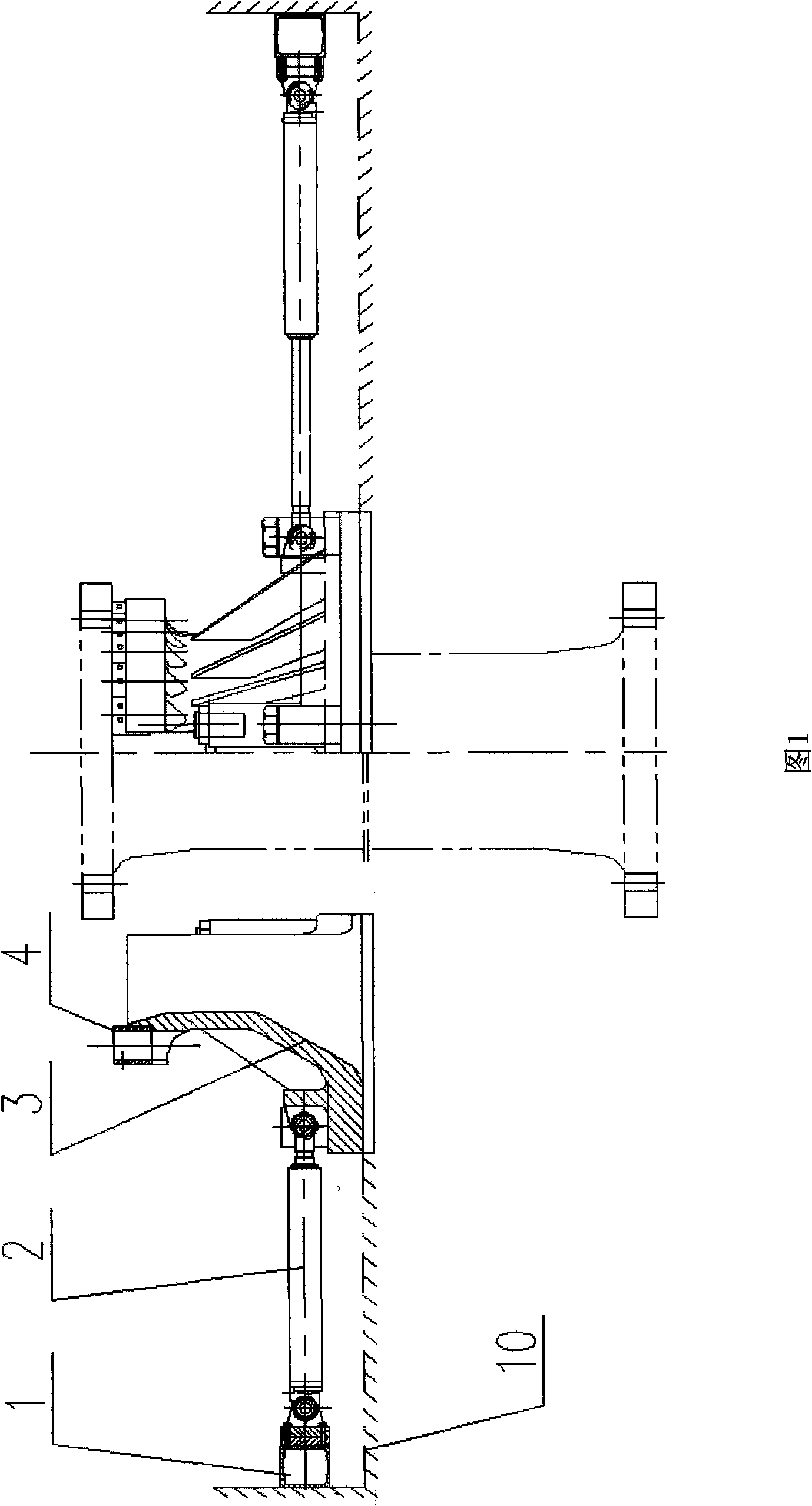

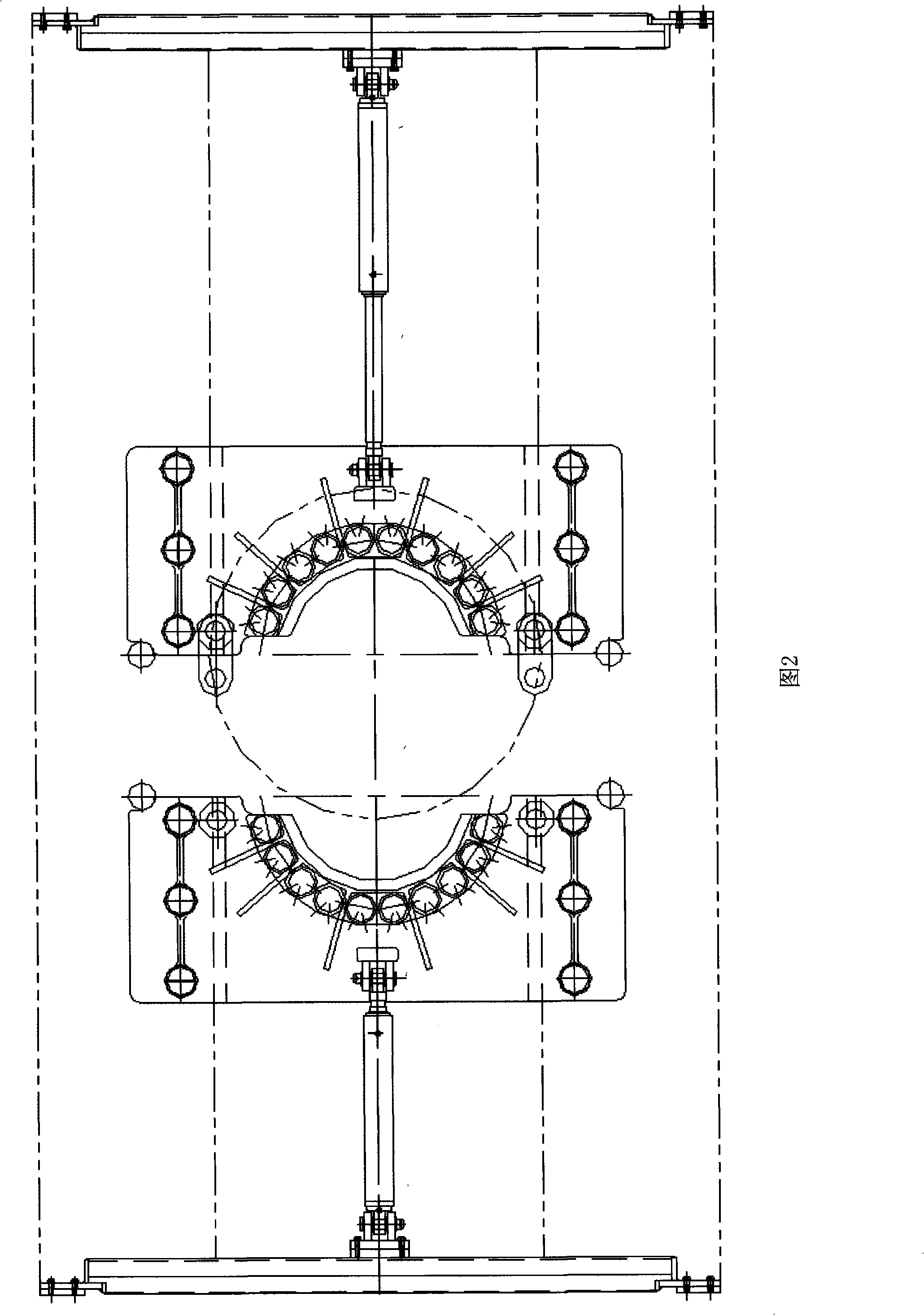

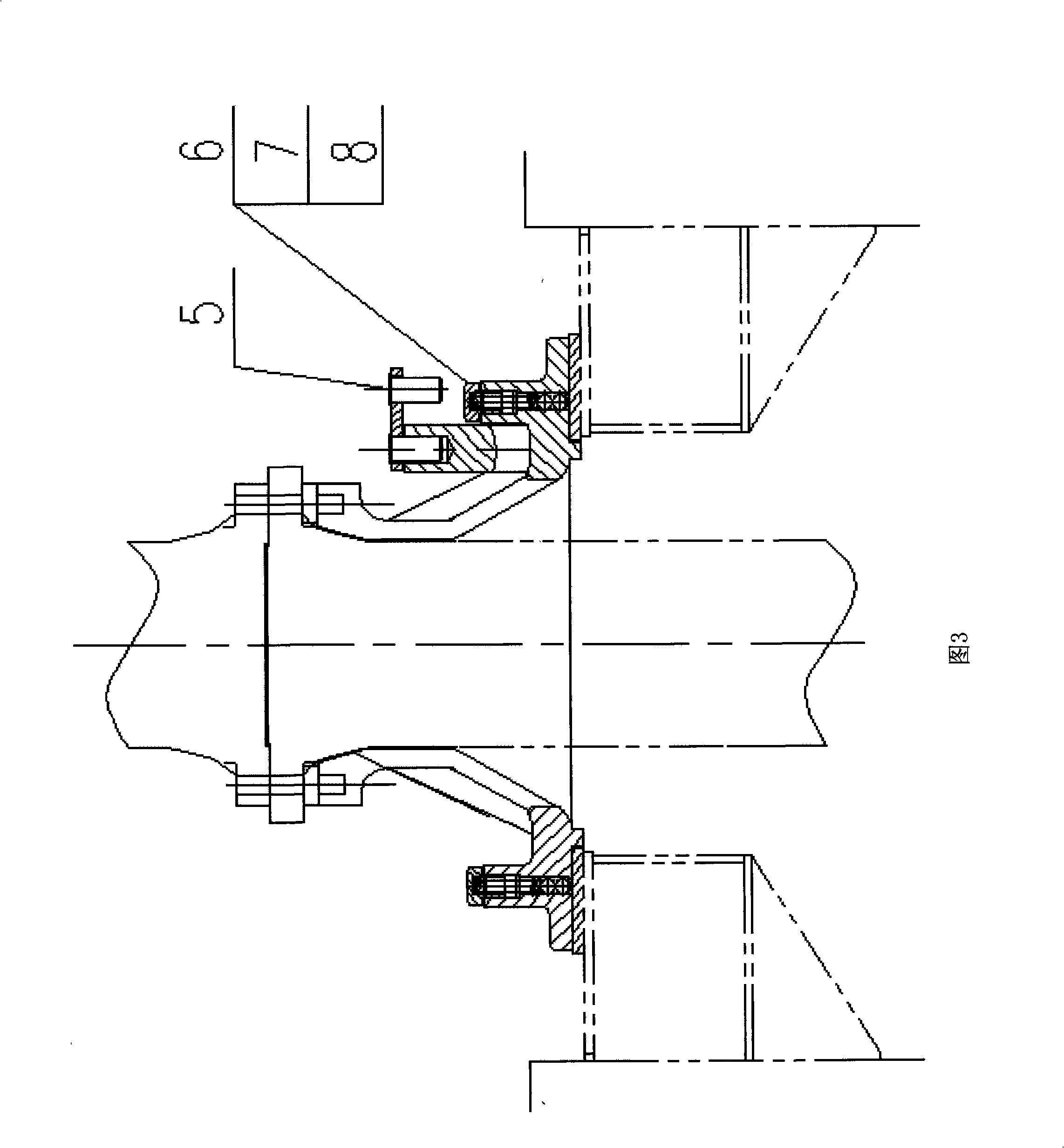

[0020] As shown in Figures 1 and 2: the clamping device used for connecting and unloading drill pipes of the present invention mainly consists of a support (1), an oil cylinder (2), a half clamping clamp (3), a bushing (4), a bolt ( 6), spring (7), steel ball (8), wherein the support (1) is fixed on the external reserved platform (10), one end of the oil cylinder (2) is connected with the support (1), and the other end is connected with the half-holding card ( 3) Connection, the semi-embracing card (3) is placed on the external reserved platform (10); the structural composition of the connected support (1), oil cylinder (2), and half-embracing card (3) is symmetrical along the axis of the oil cylinder (2) card holding device. The half-holding card (3) is designed as a special-shaped structure with a small top and a large bottom. The upper part is in the shape of a semicircular cylinder, and the lower part is a combination of a semicircular cone and a large-area flat plate; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com