Dust collector roller

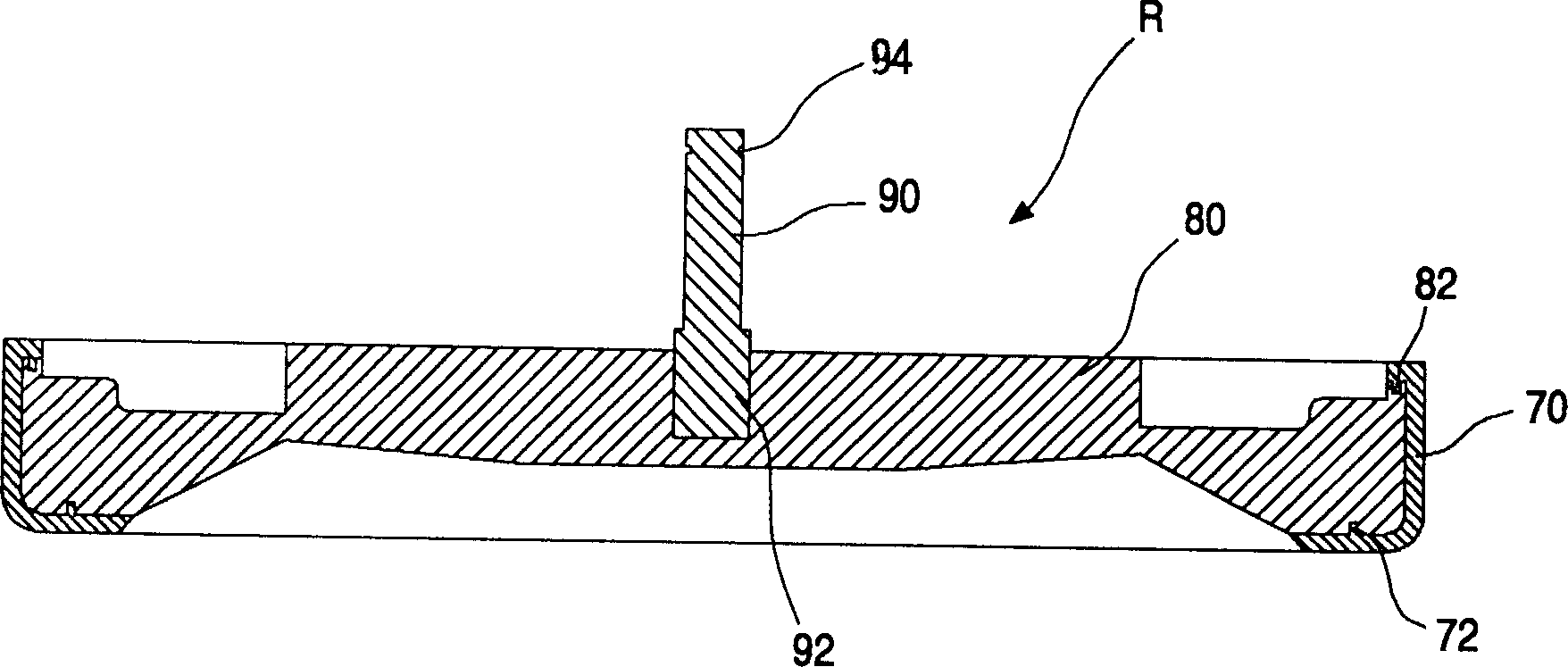

A technology of vacuum cleaners and rollers, which is applied to vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of insufficient binding force, large impact force, and rotation to prevent the wear of protrusions 72, and achieve the effect of improving binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

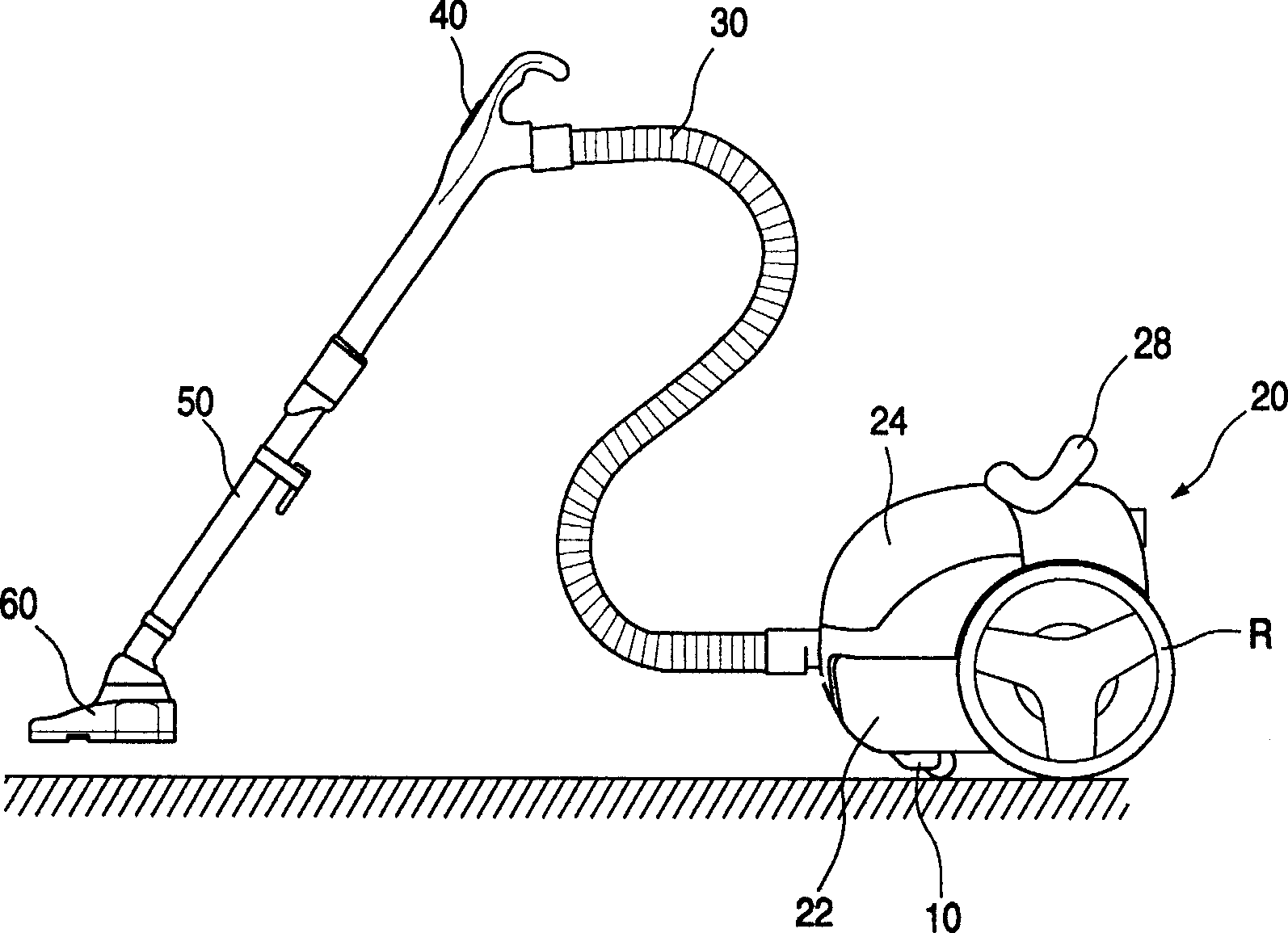

[0065] Figure 4 It is an oblique view of the appearance of the upright vacuum cleaner applying the example of the present invention.

[0066] As shown in the figure, the upright vacuum cleaner is mainly composed of the following parts: a suction nozzle body 100 that moves along the ground and can absorb air containing foreign substances; a body 200 that includes functional components that generate suction for sucking foreign substances and air; Provided on the upper part of the body 200, the user can operate the operating part 210 and the like when using the vacuum cleaner.

[0067] The said nozzle body 100 is a part which sucks in air by the suction port (not shown) provided in the bottom part. That is, the shell of the nozzle body 100 is composed of a nozzle upper shell 110 arranged on the upper side and a nozzle lower shell 120 arranged at the bottom, and the suction nozzle shell 120 should be provided with a suction port of the external air suction passage.

[0068] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com