Device facilitating measurement of hardness of workpiece

A hardness and workpiece technology, applied in the field of height-adjustable hardness testers, can solve problems such as large measurement errors and non-adjustable heights, and achieve accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

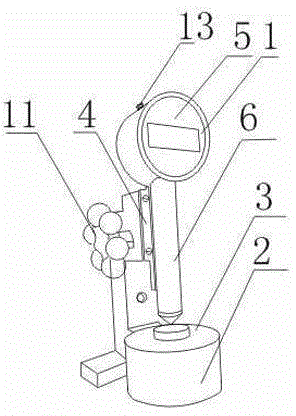

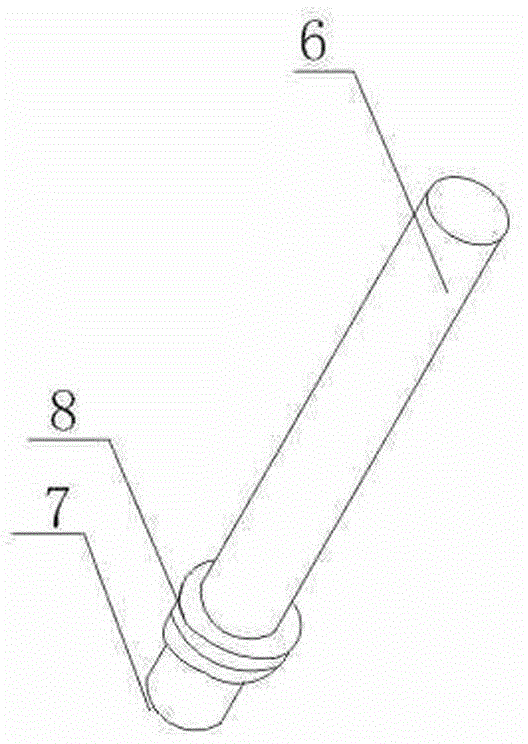

[0020] Such as figure 1 , figure 2 As shown, a device for easily measuring the hardness of a workpiece includes a hardness tester 1 and a base 2. The base 2 includes a test bench 3 and a column 4 connected to the test platform 3, wherein the column 4 is a cavity structure with an open end, and the hardness tester 1 is slidingly arranged in the column 4; the hardness tester 1 includes a cylindrical cavity shell, the hardness converter 5 is arranged in the cylindrical cavity shell, and also includes a conduit 6 connected to the cylindrical cavity shell, a test head 9 is slidably arranged in the conduit 6. A hole 7 is opened at the bottom end of the conduit 6, and an electronic coil 8 is wound above the hole 7, wherein the hardness converter 5 is electrically connected to the electronic coil 8. The hardness tester 1 also includes a transmission device 10.

[0021] The hardness tester 1 is slidingly arranged in the column 4. When the workpiece is placed on the test table 3, the...

Embodiment 2

[0023] On the basis of Embodiment 1, this embodiment also includes a handwheel 11 installed on the side of the column 4 . A bevel gear A connected to the hand wheel 11 and a bevel gear B meshed with the bevel gear A are arranged in the cavity of the column 4, wherein the axis of the bevel gear A is perpendicular to the axis of the bevel gear B and is located on the same plane. A rack is engraved on the back of the hardness tester 1, and the rack is meshed with the bevel gear B.

[0024] The hand wheel 11 is connected with the bevel gear A. When the hand wheel 11 is turned, the bevel gear A rotates, and the bevel gear A rotates to drive the bevel gear B to rotate. The bevel gear B meshes with the rack on the back of the hardness tester 1. When the hand wheel 11 turns clockwise, the bevel gear B will drive the hardness tester 1 to move downward. When the hand wheel 11 turns counterclockwise, the bevel gear B will move Drive the hardness tester 1 to move upwards, thus this embod...

Embodiment 3

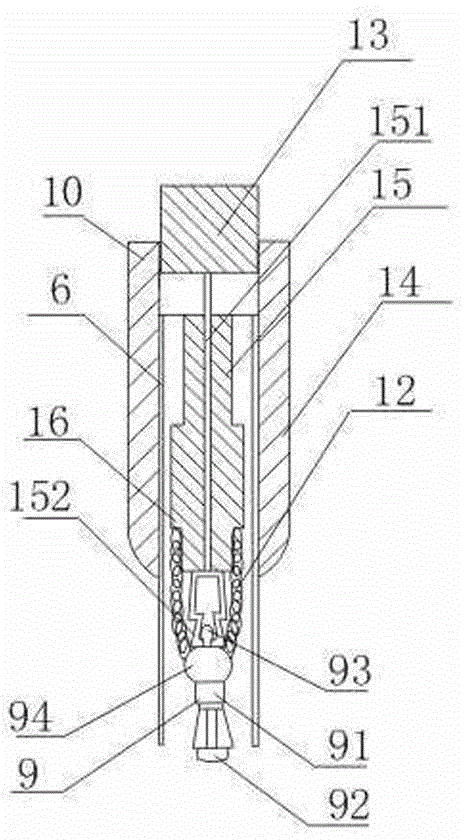

[0026] This embodiment is on the basis of embodiment 1, as image 3 , Figure 4 As shown, the transmission device 10 includes a releaser 13 located at the top of the transmission device 10, a support tube 14 sleeved outside the conduit 6 and a loading body 15 movable in the conduit 6, and a transmission sleeve sleeved on the loading body 15. sleeve 16 ; the transmission device 10 also includes a spring 12 . The loading body 15 includes a connecting pipe 151 and a gripper 152 connected to the bottom end of the connecting pipe 151. There are at least two grippers 152, and the upper end of the connecting pipe 151 is connected to the releaser 13. There is a hook at the bottom. The transmission sleeve 16 is sleeved on the connecting pipe 151, the middle part of the transmission sleeve 16 is a protruding structure, and one end of the spring 12 is connected to the lower end of the protruding structure of the transmission sleeve. When the loading body 15 is loaded, the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com