Preparation method of hydrophobic three-layer co-extrusion compound film

A three-layer co-extrusion, composite film technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

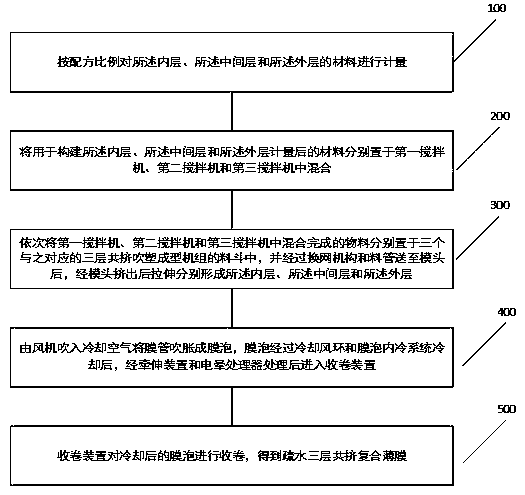

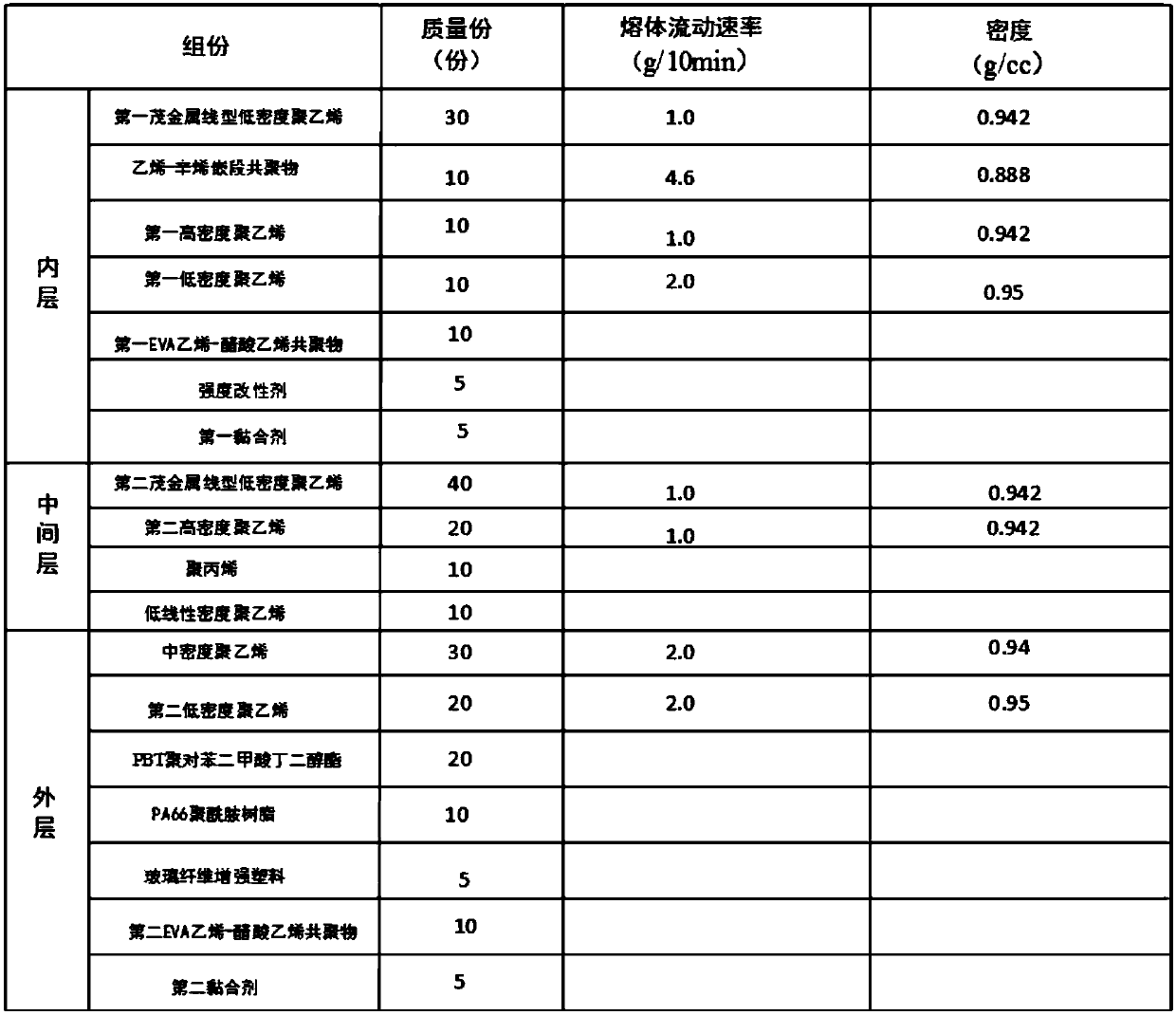

[0032] Such as figure 1 , Table 1, Table 2, Table 3 and Table 10:

[0033] Component quality, melt flow velocity and density of table 1 embodiment 1

[0034]

[0035] The rotating speed, temperature and mixing time of the first agitator of table 2 embodiment 1, the second agitator and the 3rd agitator

[0036] Speed r / min temperature °C Mixing time min first blender 300 90 8 second blender 350 80 6 third blender 200 95 8

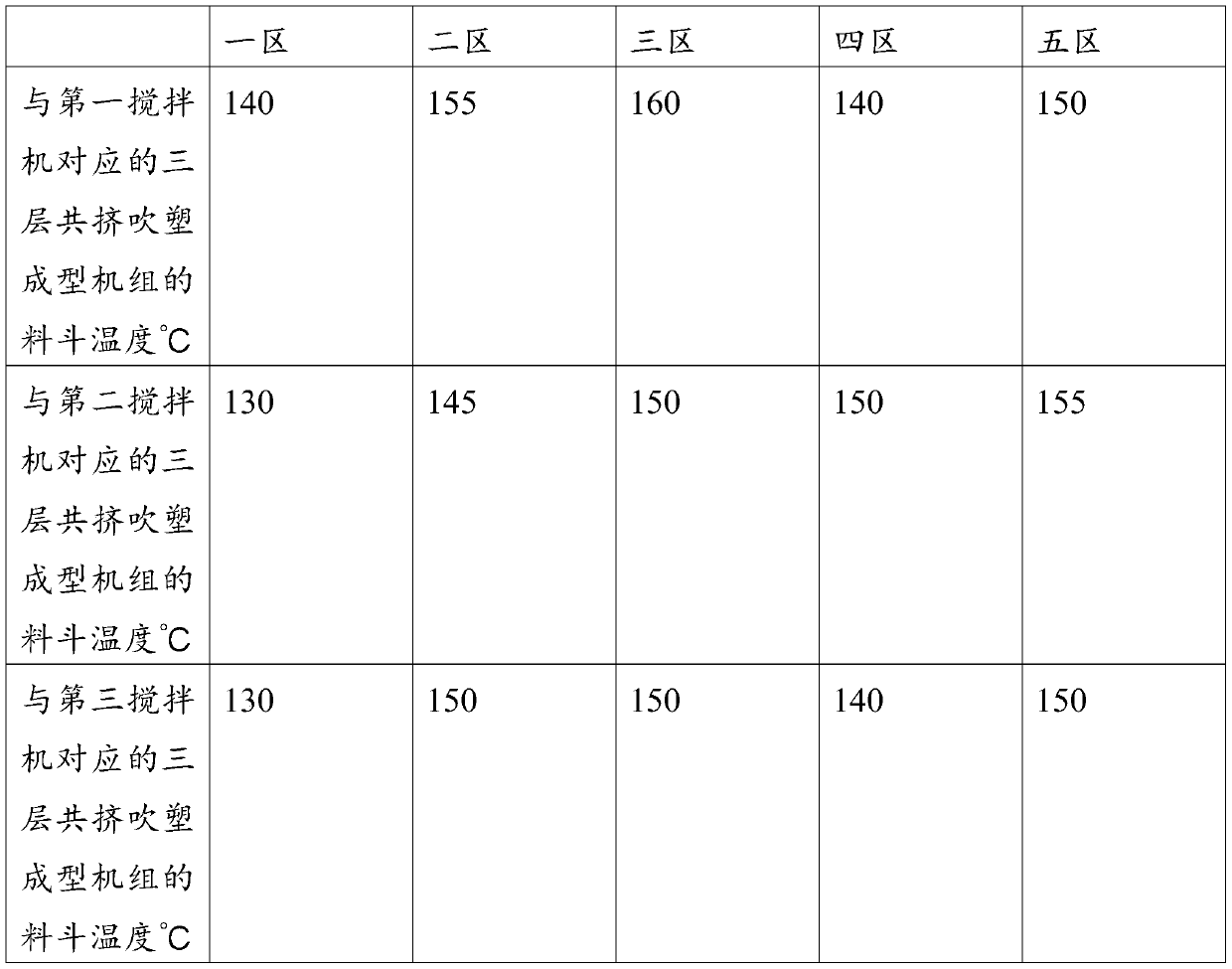

[0037] The first agitator of table 3 embodiment 1, the second agitator and the hopper temperature of the unit corresponding to the third agitator

[0038]

[0039] S100: Measure the materials of the inner layer, the middle layer and the outer layer according to the formula ratio:

[0040]The inner layer includes 30 parts of the first metallocene linear low density polyethylene, the melt flow rate is 1.0g / 10min, and the density is 0.942g / cc; 10 parts of ethylene-octene block copolymer, the melt flow rate ...

Embodiment 2

[0055] Such as figure 1 , Table 4, Table 5, Table 6 and Table 10:

[0056] Component quality, melt flow velocity and density of table 4 embodiment 2

[0057]

[0058] The rotating speed, temperature and mixing time of the first agitator of table 5 embodiment 2, the second agitator and the 3rd agitator

[0059] Speed r / min temperature °C Mixing time min first blender 350 95 9 second blender 400 90 8 third blender 300 105 10

[0060] The hopper temperature of the unit corresponding to the first agitator, the second agitator and the third agitator of table 6 embodiment 2

[0061]

[0062] S100: Measure the materials of the inner layer, the middle layer and the outer layer according to the formula ratio:

[0063] The inner layer includes 35 parts of the first metallocene linear low density polyethylene, the melt flow rate is 2.0g / 10min, and the density is 0.952g / cc; 15 parts of ethylene-octene block copolymer, the melt flow ra...

Embodiment 3

[0078] Such as figure 1 , Table 7, Table 8, Table 9 and Table 10:

[0079] Component quality, melt flow velocity and density of table 7 embodiment 3

[0080]

[0081] The rotating speed, temperature and mixing time of the first agitator of table 8 embodiment 3, the second agitator and the 3rd agitator

[0082] Speed r / min temperature °C Mixing time min first blender 400 100 10 second blender 450 100 10 third blender 400 115 12

[0083] The hopper temperature of the unit corresponding to the first agitator, the second agitator and the third agitator of table 9 embodiment 3

[0084]

[0085] S100: Measure the materials of the inner layer, the middle layer and the outer layer according to the formula ratio:

[0086] The inner layer includes 40 parts of the first metallocene linear low density polyethylene, the melt flow rate is 3.0g / 10min, and the density is 0.962g / cc; 20 parts of ethylene-octene block copolymer, the melt flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com