Tea hot air water-removing machine

A hot air greening machine and tea technology, which are applied in the direction of tea treatment before extraction, can solve the problems of affecting the quality of tea, affecting the greening effect, and easy scorching of fresh leaves, so as to improve the utilization rate of hot air, improve the drying effect, and the drying effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

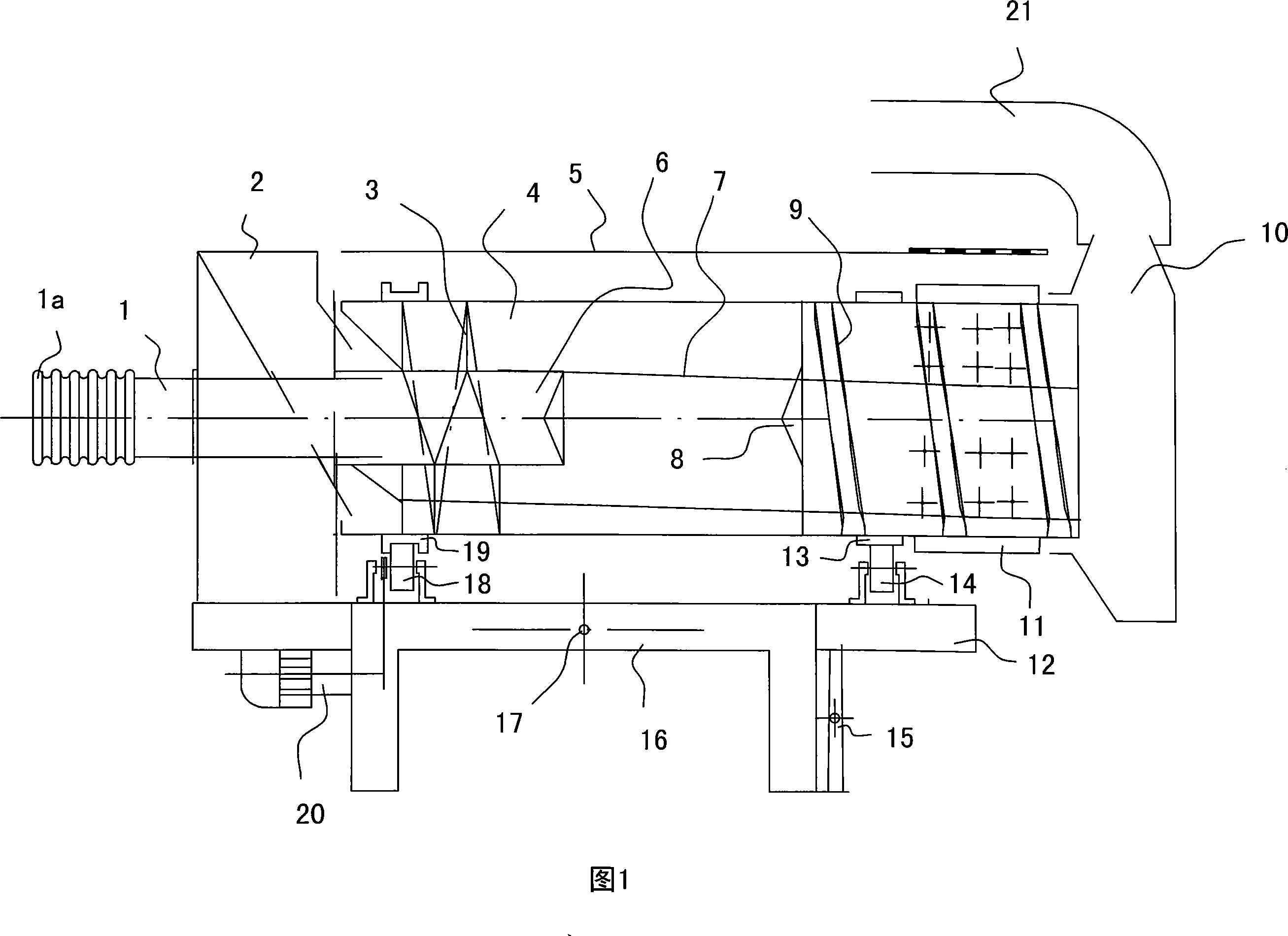

[0017] See Figure 1. Frame 16 is firmly on the ground, and left and right is long and forms a shelving groove, and frame 12 is shelved in the shelving groove of machine base 16 in suspension state through rotary pin 17, and is fixedly positioned under the assistance of angle adjustment mechanism 15. Turn the handle on the angle adjustment mechanism 15 to adjust the horizontal inclination angle of the cylinder 4. Angle adjustment mechanism 15 can adopt manual or electric screw nut mechanism, also can adopt four-bar linkage. A pair of friction wheels 18 and a pair of supporting wheels 14 are arranged symmetrically on the frame 12. The friction wheels 18 and the supporting wheels 14 are respectively protruded on the outer edges of the friction wheel rail 19 and the supporting wheel rail 13. Driven by the transmission mechanism 20, the The drum 4 rotates on four wheels.

[0018] The left and right ends of the drum 4 are respectively a tea inlet and a tea outlet. The tea inlet i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com