LED (light emitting diode) lampshade connecting structure

A technology of LED lampshade and connection structure, which is applied to lighting and heating equipment, point light sources, lighting devices, etc., can solve the problems of injection molding defects, short service life, low yield, etc., and achieve good use stability and reduce production costs. , The effect of less injection molding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

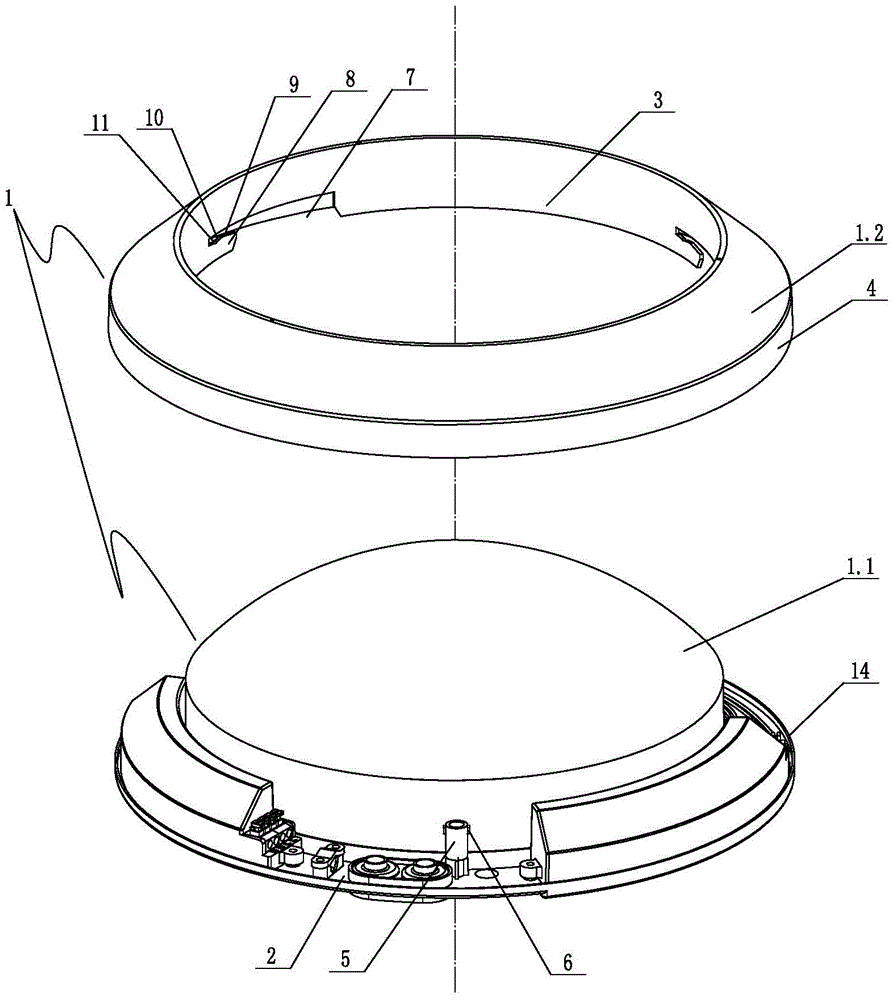

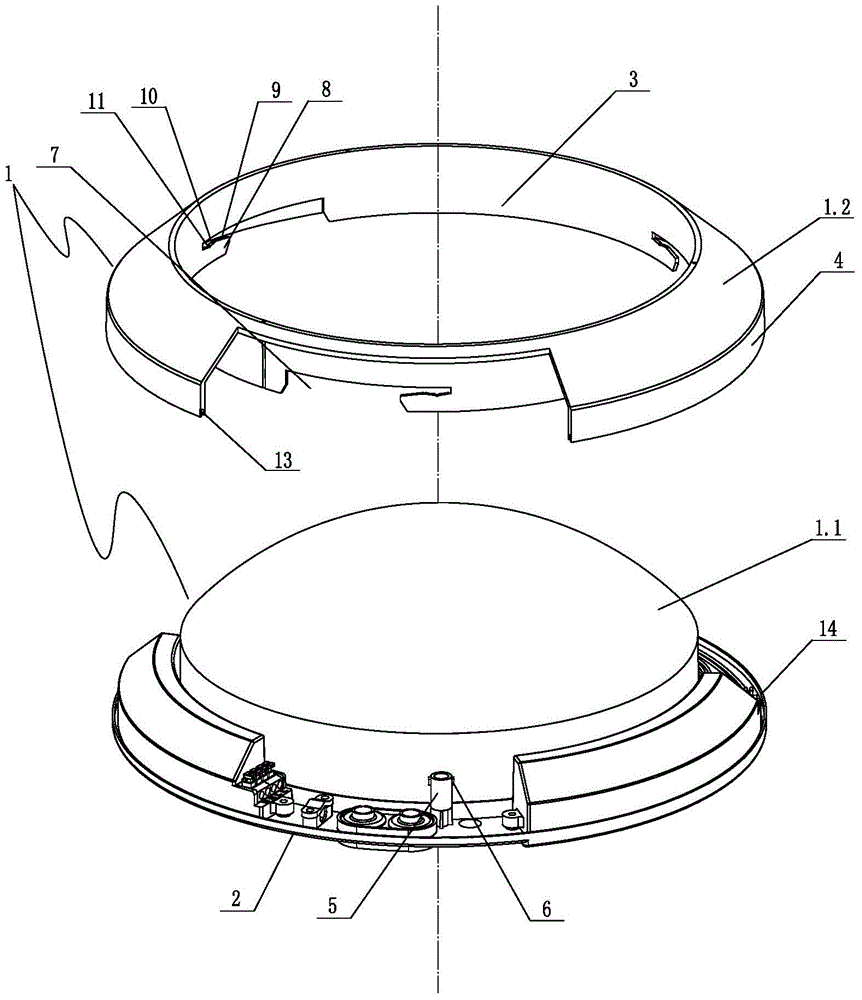

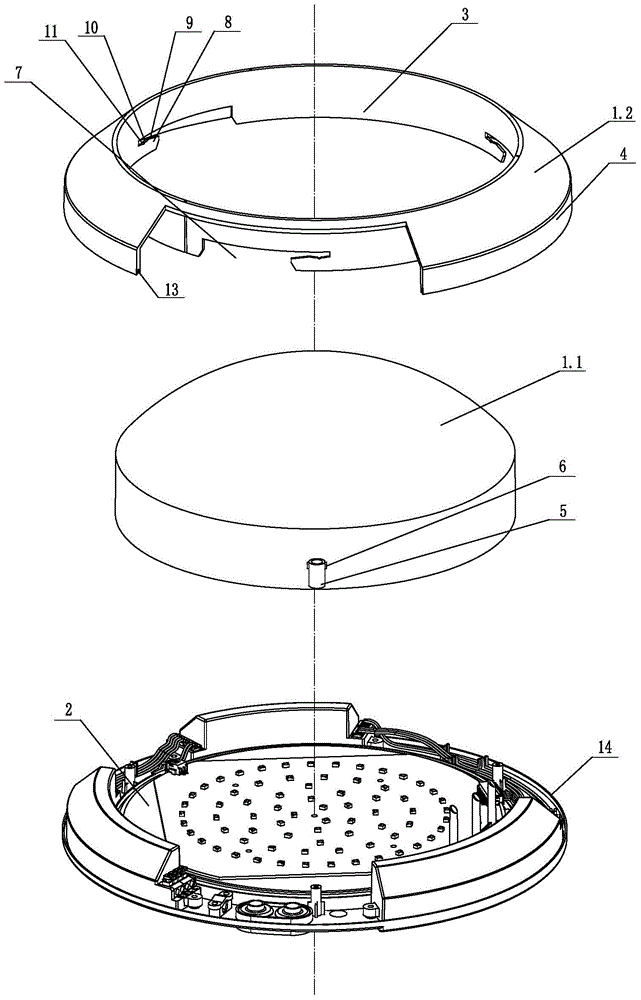

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 The LED lampshade connection structure shown includes a lampshade 1 and a lamp holder 2. The lampshade 1 is divided into a spherical inner cover 1.1 and an annular outer cover 1.2, and the outer diameter of the inner cover 1.1 is equal to that of the outer cover 1.2. Inner diameter, the outer cover 1.2 is provided with an annular inner dust-proof plate 3 and an outer dust-proof plate 4; the inner cover 1.1 is provided with at least two fixing columns 5 connected to the lamp holder 2 (three in this example) 1, can also be two, four or five, etc.), the number of fixed columns 5 is set according to the size of the lamp and the material of the inner cover 1.1, the axis of the fixed columns 5 is parallel to the axis of the inner cover 1.1, and the fixed columns 5 Evenly distributed alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com