Thermal simulation method of thermal-mechanical treatment of high strength automobile steel impact specimen

A technology of deformation heat treatment and impact specimen, applied in the field of thermal simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] A kind of material is the thermal simulation method of the deformation heat treatment of the impact sample of 22MnB5 hot-formed steel, specifically comprises the following steps:

[0112] Step 1, perform (A) and (B), (A) and (B) in no order:

[0113] (A) Determine the size of the simulated sample:

[0114] Based on the size of the standard impact sample, determine the size of the simulated sample:

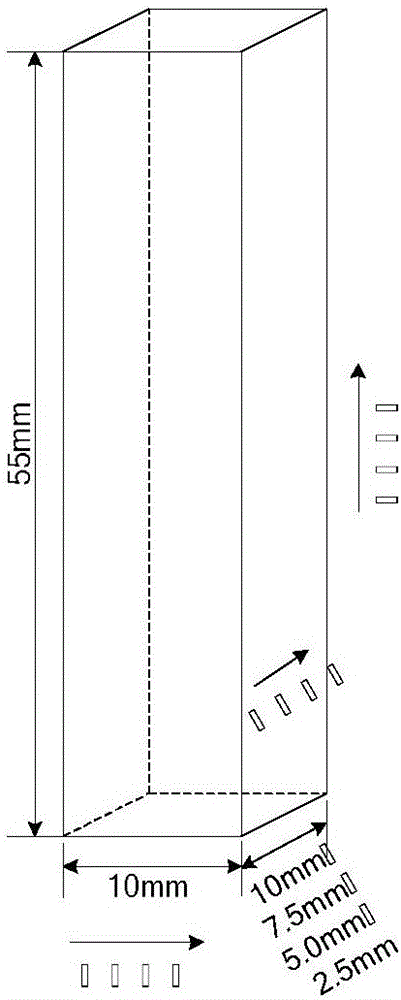

[0115] The standard impact sample is a cuboid, and the specific dimensions are as follows: figure 1 As shown, suppose: the length of the bottom of the cuboid is H 长 = The width of the base of the cuboid is H 宽 =10mm, the height of the cuboid is H 高 = 55mm.

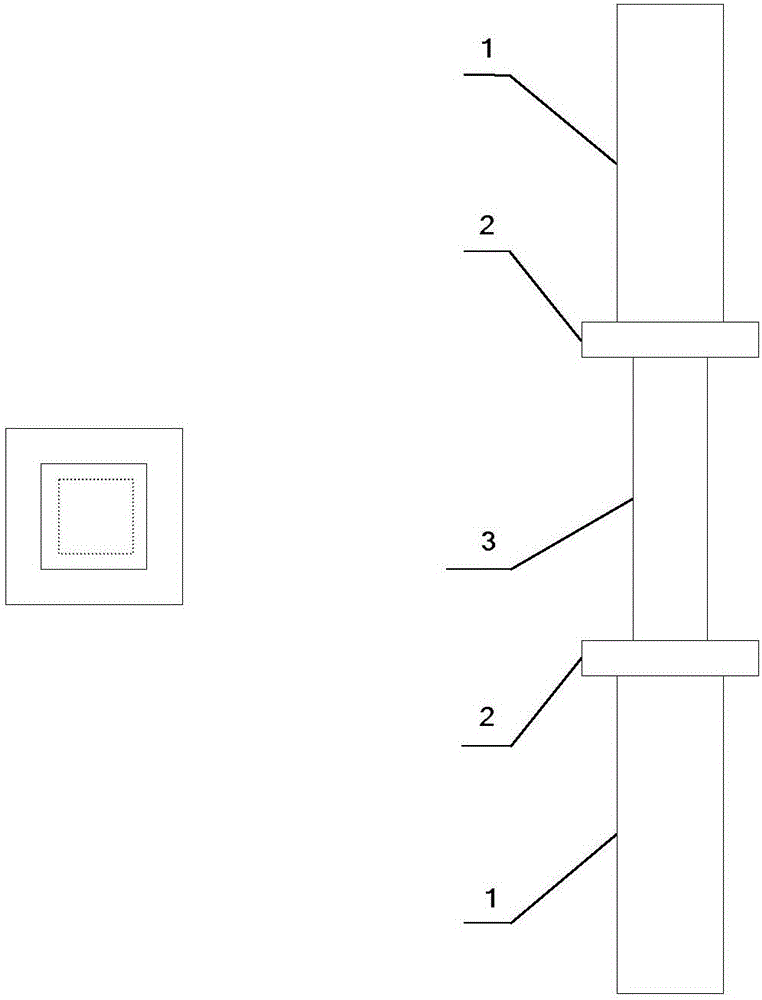

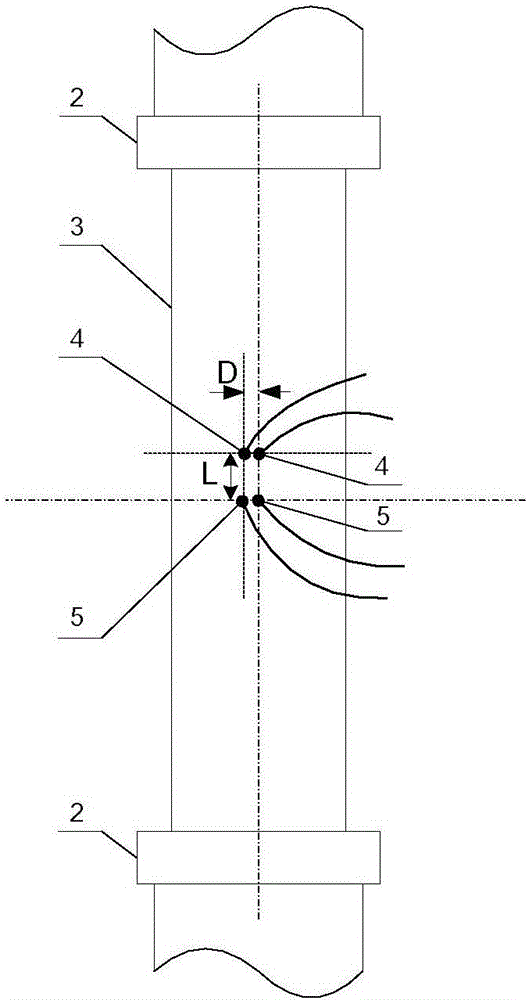

[0116] The structure of the simulated sample is an integrated structure. The simulated sample is composed of a simulated cuboid, 2 stepped platforms and 2 clamping ends. The same stepped platforms are respectively arranged on both sides of the two bottom surfaces of the simulated cuboid. The two sides are respectiv...

Embodiment 2

[0151] A thermal simulation method for deformation heat treatment of impact specimens of high-strength plastic heat-forming experimental steel, the composition and mass percentage of the high-strength plastic heat-forming experimental steel are: C: 0.19, Si: 1.55, Mn: 1.53 , Ni: 0.95, Cr: 1.01, Cu: 1.01, B: 0.0027, Al: 0.025, Ti: 0.033, Mo: 0.45, S: 0.004, P: 0.008, and the balance is Fe, specifically including the following steps:

[0152] Step 1, perform (A) and (B), (A) and (B) in no order:

[0153] (A) Determine the size of the simulated sample:

[0154] Based on the size of the standard impact sample, determine the size of the simulated sample:

[0155] The standard impact sample is a cuboid, and the specific dimensions are as follows: figure 1 As shown, suppose: the length of the bottom of the cuboid is H 长 = The width of the base of the cuboid is H 宽 =10mm, the height of the cuboid is H 高 = 55mm.

[0156] The structure of the simulated sample is an integrated stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact energy at room temperature | aaaaa | aaaaa |

| Impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com