FPGA-based highly-integrated high-precision control system for micro flywheel

A high-integration, control system technology, applied in the fields of low power consumption control, high reliability and high precision, can solve the problems of slow single-chip microcomputer, complex peripheral circuits, signal processing, transmission lag, etc., to achieve reduced lag, The effect of reducing hardware errors and reducing system power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

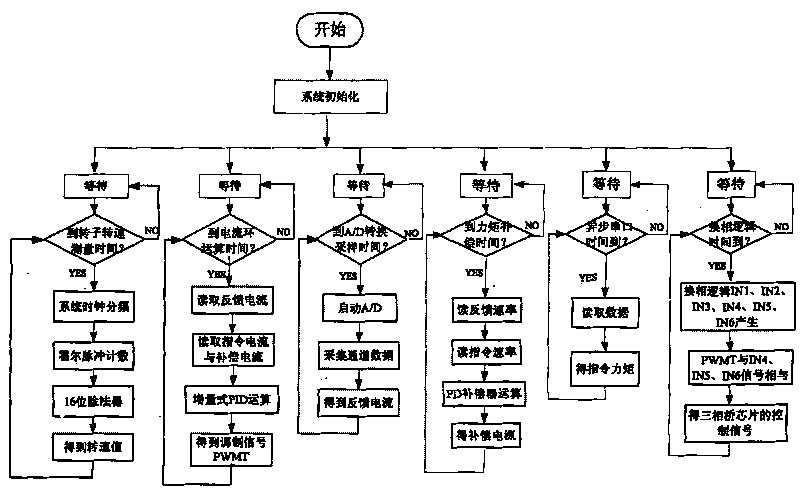

[0018] In this embodiment, the input steady DC voltage is 28V, the tiny flywheel motor is a three-phase permanent magnet brushless DC motor with 6 pairs of poles, and 12 switch-type Hall sensors are placed on the stator of the flywheel motor at intervals of 30° for speed measurement. Motor phase resistance R in the present invention 1 =0.4Ω, phase inductance Lm=4.8μH, PWM modulation frequency 20KHz. The digital controller adopts EPF10K30 of Altera Company.

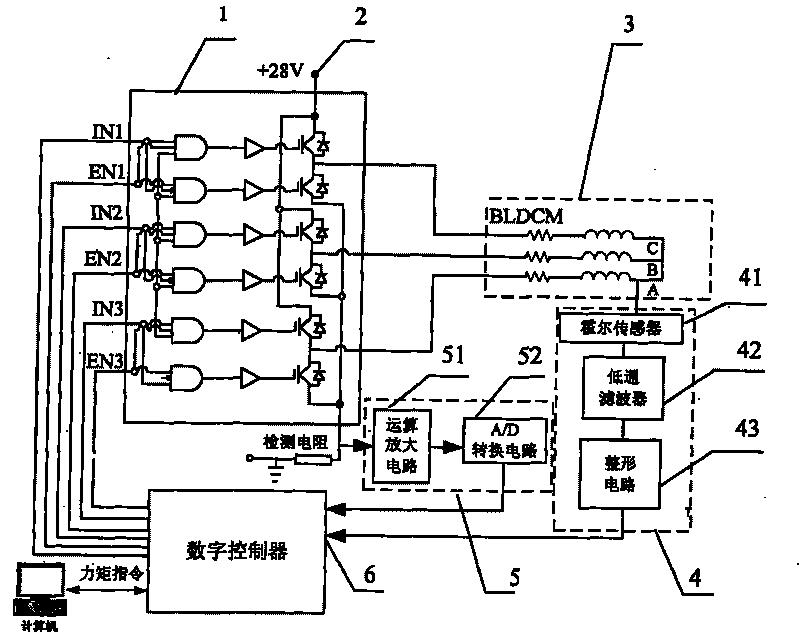

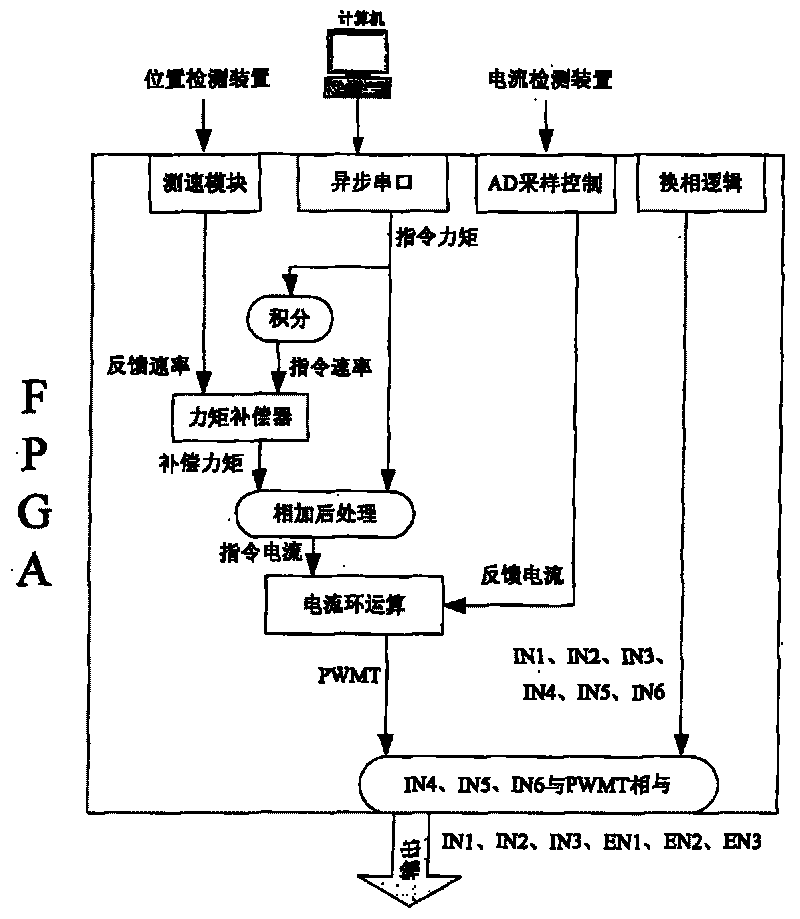

[0019] Such as figure 1 As shown, this embodiment is mainly composed of a DC power supply 2 , a digital controller 6 , a three-phase bridge integrated drive chip 1 , a permanent magnet brushless DC motor 3 , a current detection device 5 , and a position detection device 4 . The constant DC power supply 2 provides a constant voltage to the three-phase bridge integrated driver chip 1, the three-phase bridge integrated driver chip 1 integrates a star-shaped three-phase six-state inverter and its driving circuit, and the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com