Method for creating a fibrous substance suspension used for producing a tissue web or hygiene web

a fibrous suspension and tissue technology, applied in papermaking, non-fibrous pulp addition, coatings, etc., can solve the problems of large water consumption, low beating degree, and often conflict with mechanical properties requirements, so as to optimize the efficiency and cost-effectiveness of the production of corresponding tissue or hygiene products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

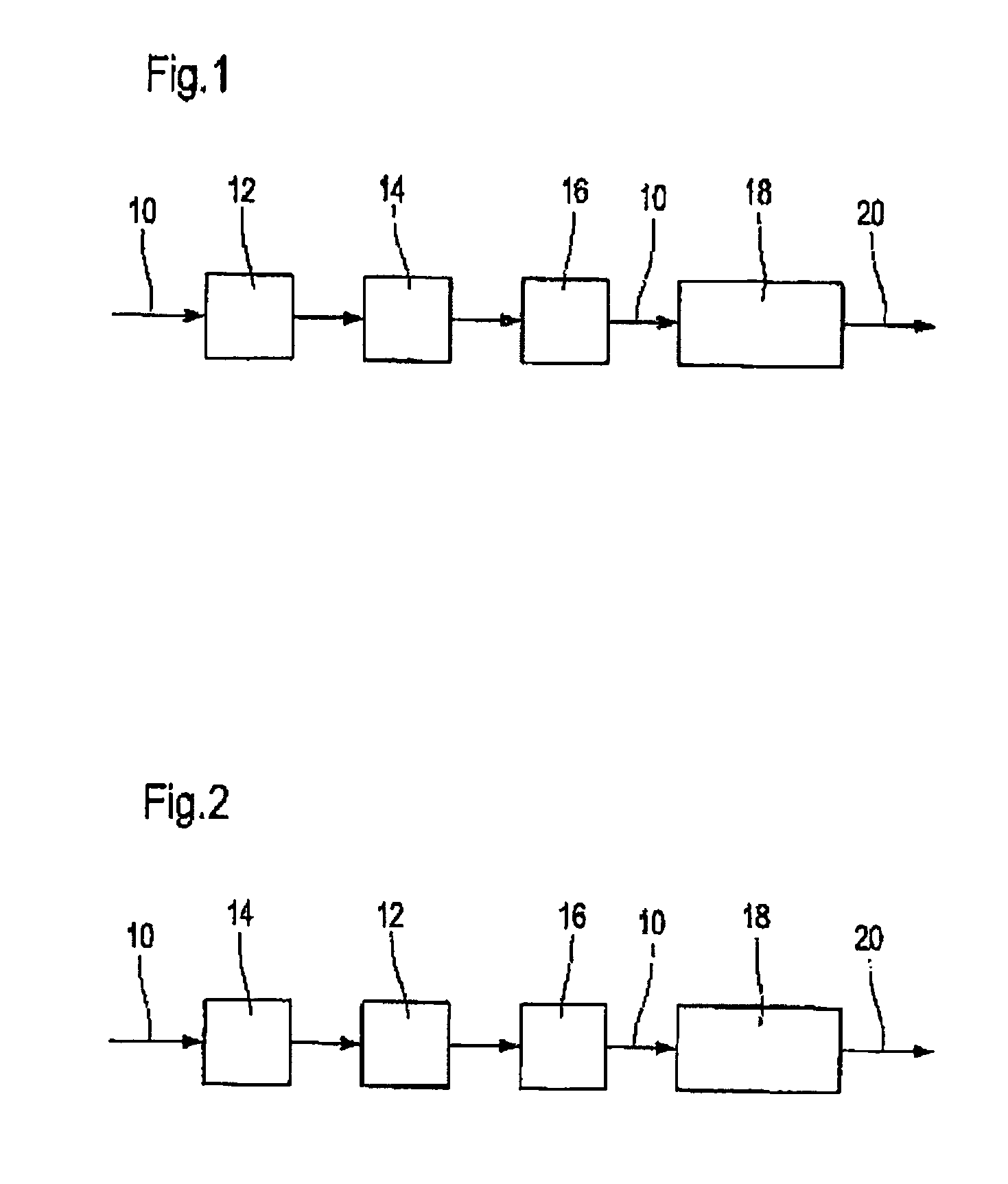

[0070]FIG. 1 shows an exemplary embodiment in which the fibrous suspension 10 is first fed to the “Fiber Loading™” process 12 and subsequently is treated accordingly in a treatment unit 14 comprising, e.g., a refiner or the like. Subsequently, free calcium carbonate can be washed out in a washing step 16, if necessary. As described above, such a washing step 16 can be omitted. The fibrous suspension 10 is subsequently fed to a tissue machine 18, where the desired tissue or hygiene web 20 (and the respective final tissue product) is obtained.

[0071] The exemplary embodiment shown in FIG. 2 differs from that in FIG. 1 only in that the fibrous suspension 10 first is fed to the treatment unit 14 comprising, e.g., a refiner or the like, and then to the “Fiber Loading™” process. The washing step 16 is not obligatory in this case either.

[0072] In both cases, the fibers contained in the fibrous suspension 10 are directly loaded in an online process with a filler in the tissue material prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com