Method for weakening phase-change texture of high-niobium titanium-aluminum alloy

A titanium-aluminum alloy and high-niobium technology, which is applied in the field of weakening the phase change texture of high-niobium titanium-aluminum alloy, can solve the problems of reduced production efficiency, long holding time, and α grain growth, so as to reduce stress concentration and weaken Cracking tendency, short cycle time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

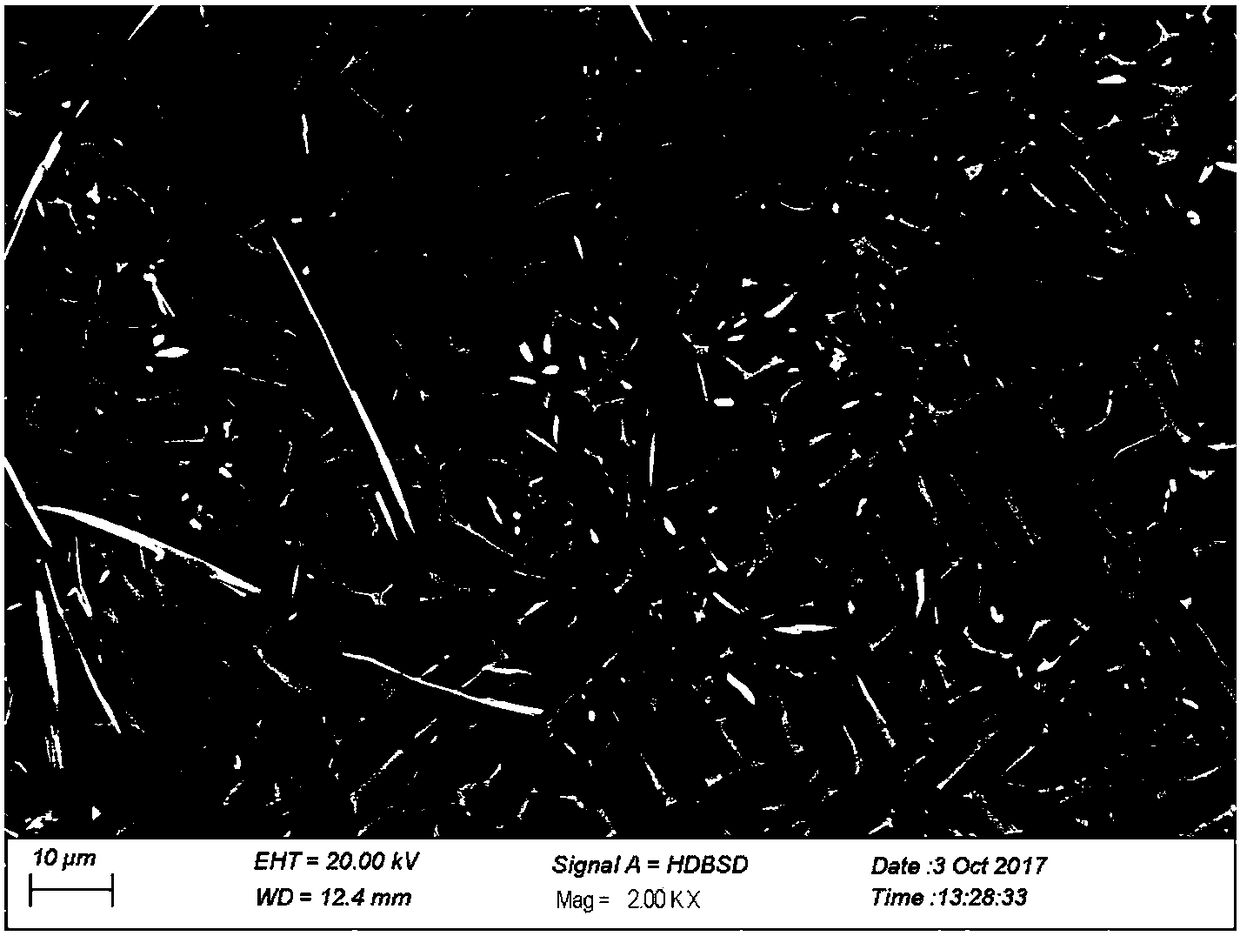

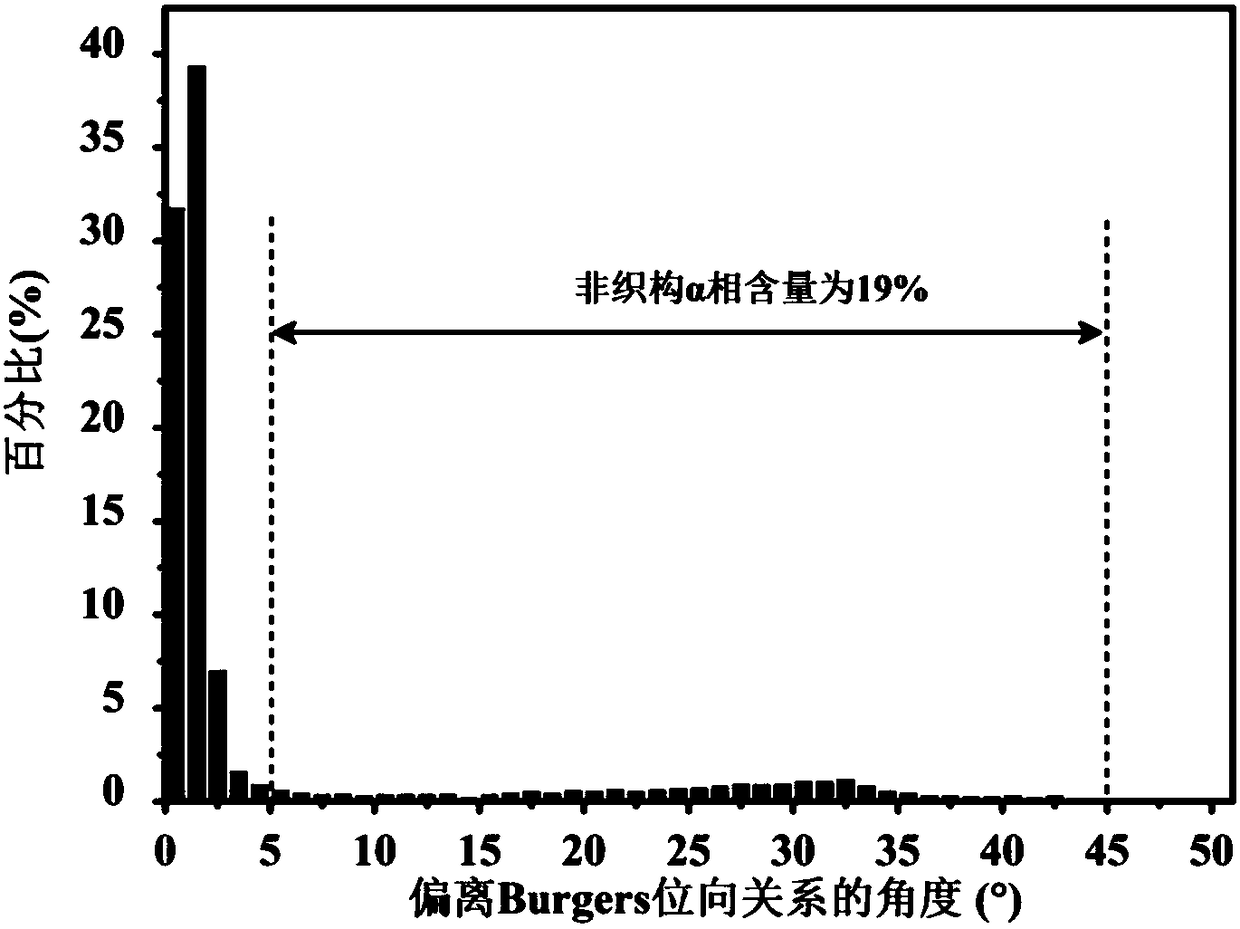

Embodiment 1

[0030] Figure 7 It is a flowchart of an embodiment of the present invention, such as Figure 7 As shown, a method for weakening the phase transformation texture of high niobium titanium aluminum alloy includes:

[0031] (1) Preparation of high-niobium titanium-aluminum alloy test rods. Wire cutting is used to intercept alloy test rods of Φ8×12 mm. The high-niobium titanium-aluminum alloy is Ti40Al8Nb0.5B alloy. The obtained high-niobium-titanium-aluminum alloy test rod was ground and ultrasonically cleaned.

[0032] (2) Vacuumize and backfill with argon, put the test rod into the thermal simulation testing machine, and use the pressure head to fix the test rod. The chamber of the thermal simulator is evacuated to 1 Pa, and after the evacuation is completed, the chamber is filled with argon to 0.06 MPa. Repeat the above-mentioned vacuuming-argon backfilling process once, and then enter step 3 to heat the alloy test rod.

[0033] (3) Heating. The high-niobium titanium-alumi...

Embodiment 2

[0038] Figure 7 It is a flowchart of an embodiment of the present invention, such as Figure 7 As shown, a method for weakening the phase transformation texture of high niobium titanium aluminum alloy includes:

[0039] (1) Preparation of high-niobium titanium-aluminum alloy test rods. Wire cutting is used to cut alloy test rods of Φ8×12 mm. The high-niobium titanium-aluminum alloy is Ti45Al10Nb0.5B alloy. The obtained high-niobium-titanium-aluminum alloy test rod was ground and ultrasonically cleaned.

[0040] (2) Vacuumize and backfill with argon, put the test rod into the thermal simulation testing machine, and use the pressure head to fix the test rod. Evacuate the chamber of the thermal simulator to 9 x 10 -2 Pa, fill the chamber with argon gas to 0.06MPa after vacuuming. Repeat the above-mentioned vacuuming-argon backfilling process twice, and then proceed to step 3 to heat the alloy test rod.

[0041] (3) Heating. The high-niobium titanium-aluminum alloy test rod wa...

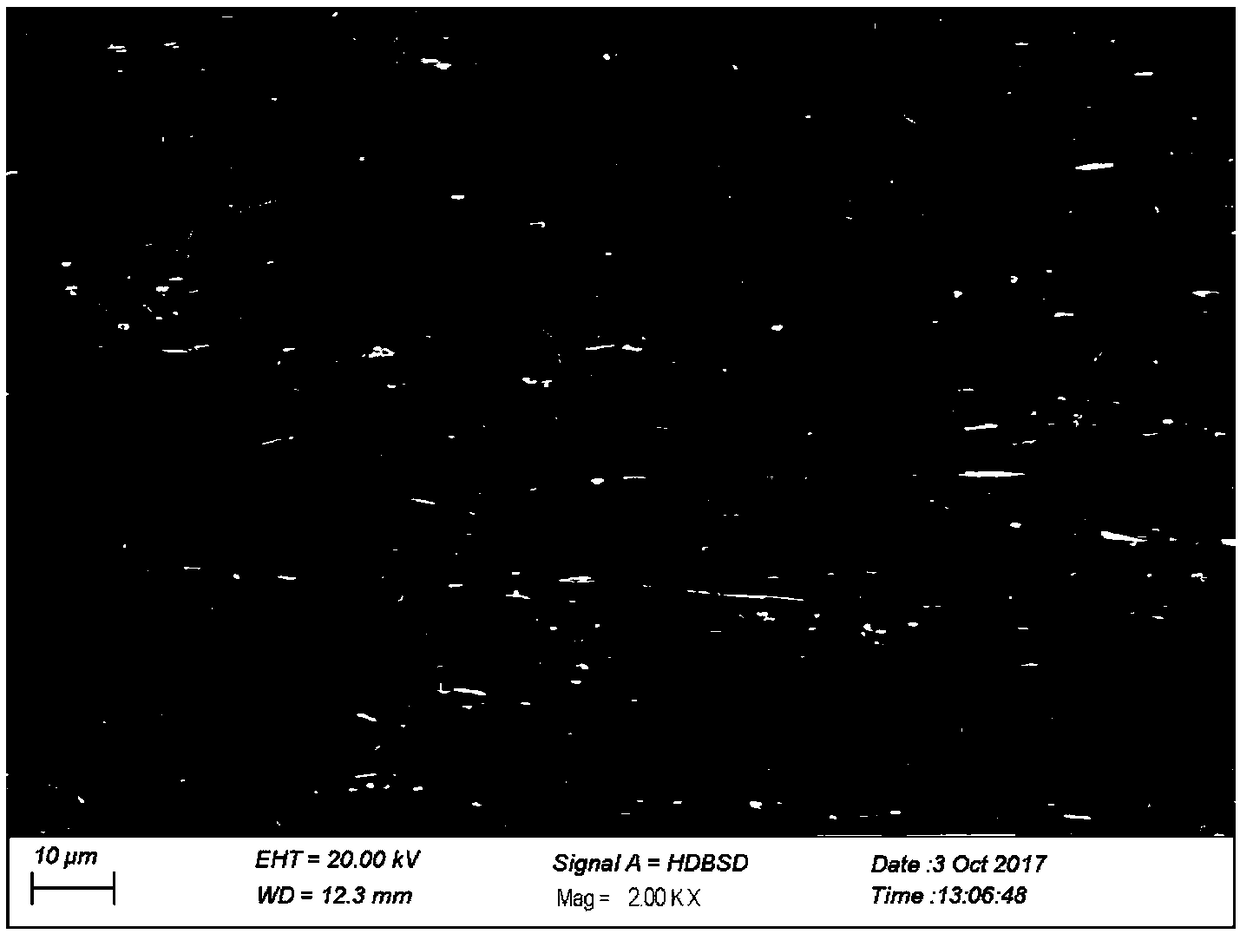

Embodiment 3

[0045] Figure 7 It is a flowchart of an embodiment of the present invention, such as Figure 7 As shown, a method for weakening the phase transformation texture of high niobium titanium aluminum alloy includes:

[0046] (1) Preparation of high-niobium titanium-aluminum alloy test rods. Wire cutting is used to intercept alloy test rods of Φ8×12 mm. The high-niobium titanium-aluminum alloys are Ti42Al5Nb1B alloys. The obtained high-niobium-titanium-aluminum alloy test rod was ground and ultrasonically cleaned.

[0047] (2) Vacuumize and backfill with argon, put the test rod into the thermal simulation testing machine, and use the pressure head to fix the test rod. The chamber of the thermal simulator is evacuated to 0.4×10-1Pa, and after the evacuation is completed, the chamber is filled with argon to 0.06MPa. Repeat the above-mentioned vacuuming-argon backfilling process once, and then enter step 3 to heat the alloy test rod.

[0048] (3) Heating. The high-niobium titanium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com