Preparation method for Nb-Si-based complex alloy

A technology of alloy and equipment, which is applied in the field of changing the structure control of Nb-Si-based multi-component alloys, can solve the problems of reducing plasticity and ductility of materials at room temperature, reducing size, and coarse structure, so as to improve room temperature performance, reduce processing costs, and avoid performance-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

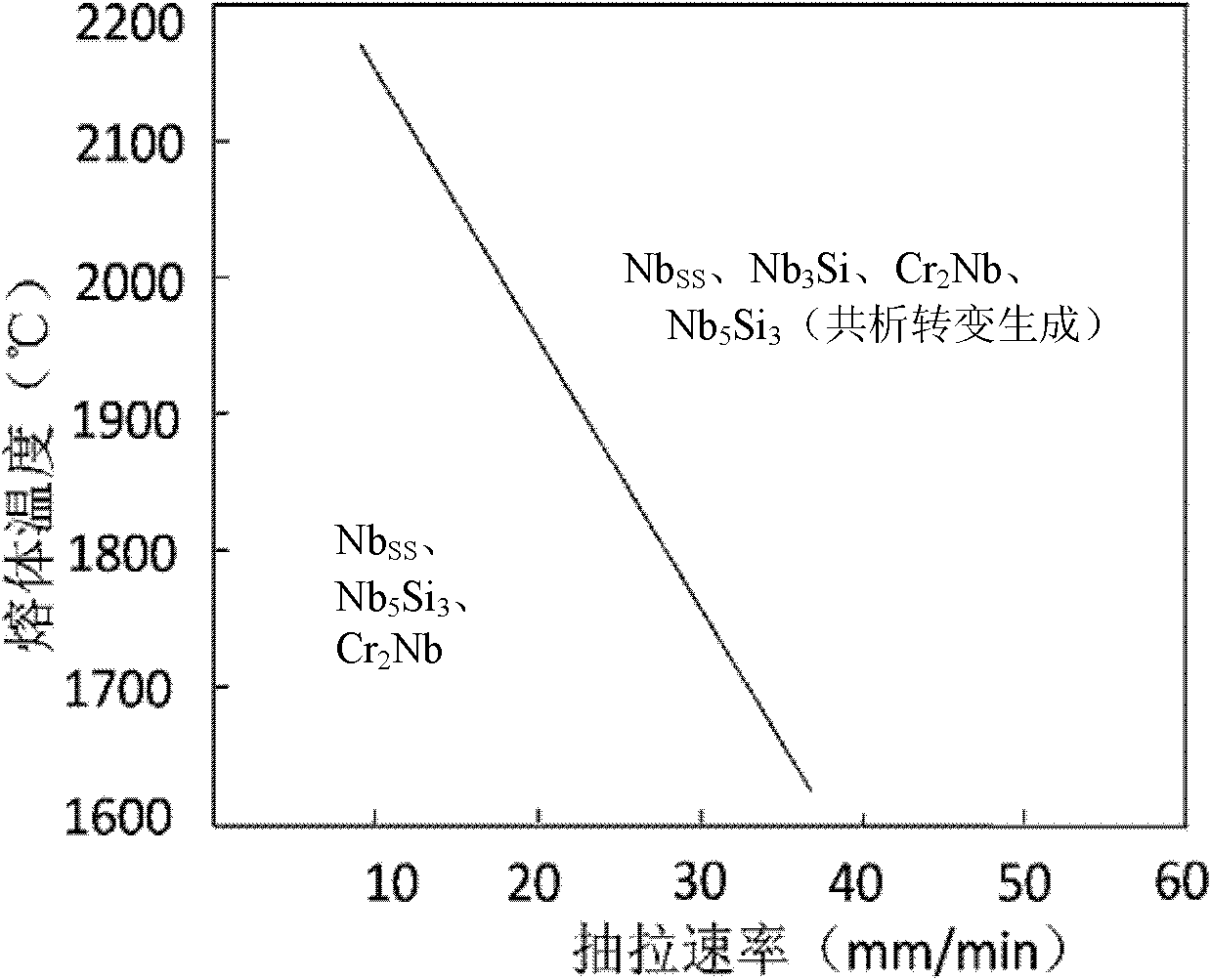

[0027] The nominal composition of embodiment 1 is Nb 50 Si 12 Ti 24 al 2 Cr 10 Hf 2

[0028] Step 1: Prepare master alloy ingot

[0029] 99.8wt% niobium (Nb), 99.9wt.% silicon (Si), 99.8wt.% titanium (Ti), 99.9wt.% aluminum (Al), 99.9wt.% chromium (Cr), 99.8wt.% hafnium (Hf) according to the nominal composition ratio;

[0030] Vacuum non-consumable electric arc furnace is used for melting, and the vacuum degree of the vacuum chamber of non-consumable electric arc furnace is 3×10 -3 Pa, and then filled with high-purity argon (mass percentage purity 99.99%) to make the vacuum of the vacuum chamber to 0.5×10 5 Pa; the alloy ingot was repeatedly smelted four times to ensure uniform composition, and the current during the smelting process was 1300A to prepare a 1.5kg master alloy ingot;

[0031] Step 2: Cut the test rod from the master alloy ingot by wire cutting method, the diameter of the test rod is about 14mm; then use sandpaper to clean the scale on the surface of the...

Embodiment 2

[0038] Embodiment 2 Nominal composition is Nb 48 Si 12Ti 22 al 2 Cr 14 Hf 2

[0039] Step 1: Prepare master alloy ingot

[0040] 99.8wt% niobium (Nb), 99.9wt.% silicon (Si), 99.8wt.% titanium (Ti), 99.9wt.% aluminum (Al), 99.9wt.% chromium (Cr), 99.8wt.% hafnium (Hf) according to the nominal composition ratio; the vacuum degree of the vacuum chamber of the vacuum non-consumable electric arc furnace is 4×10 -3 Pa, and then filled with high-purity argon (mass percentage purity 99.99%) to make the vacuum of the vacuum chamber to 0.8×10 5 Pa; the alloy ingot was repeatedly smelted four times to ensure uniform composition, and the current during the smelting process was 800A to prepare a 1.5kg master alloy ingot;

[0041] Step 2: Cut the test rod from the master alloy ingot by wire cutting method, the diameter of the test rod is about 14mm; then use sandpaper to clean the scale on the surface of the test rod, wash it with acetone, and dry it at a drying temperature of 100 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com