Bismuth telluride nanoparticle strengthened tin, silver and copper solder and using method thereof

A technology of nano-particles and bismuth telluride, applied in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of nano-particle coarsening, nano-particle loss, nano-particle and tin-silver-copper solder interface, etc. Achieve the effect of slow coarsening process, low loss rate and slow down coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

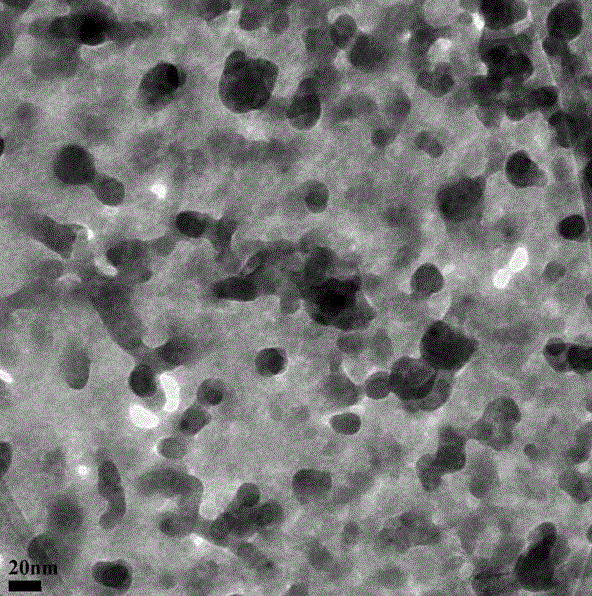

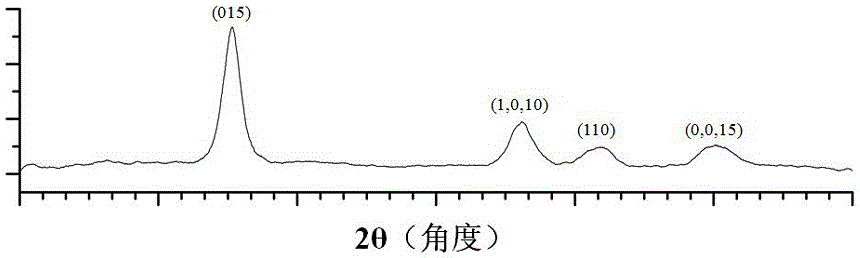

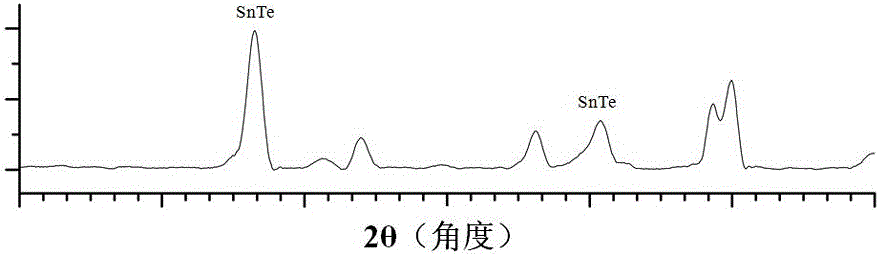

[0033] The solder of this embodiment consists of Bi in weight percent 2 Te 3 Nanoparticles 0.5%, Sn-3.0Ag-0.5Cu micron powder 87.5% and rosin flux 12%, with a total weight of 10 g.

[0034] Methods of using solder include:

[0035] Step 1, using a planetary mixer to mix Bi 2 Te 3 The nanoparticles are evenly stirred with the rosin flux. The stirring revolution speed is 1000 revolutions per minute, the autopropagation speed is 800 revolutions per minute, and the stirring time is 150 s.

[0036] Step 2, adding Sn-3.0Ag-0.5Cu micron powder into Bi 2 Te 3 The mixture of nanoparticles and flux is stirred using a planetary mixer to prepare Bi 2 Te 3 Nanoparticle Reinforced Sn-3.0Ag-0.5Cu Solder Paste. The stirring revolution speed is 800 rpm, the autorotation speed is 800 rpm, and the stirring time is 120 s.

[0037]Step 3, using Sn-3.0Ag-0.5Cu solder paste to form solder joints through a reflow soldering process. The welding peak temperature is 240 ℃, and the time above ...

Embodiment 2

[0042] The solder of this embodiment consists of Bi in weight percent 2 Te 3 Nanoparticles 1%, Sn-3.0Ag-0.5Cu micron powder 87% and rosin flux 12%, with a total weight of 10 g.

[0043] Methods of using solder include:

[0044] Step 1, using a planetary mixer to mix Bi 2 Te 3 The nanoparticles are evenly stirred with the rosin flux. The stirring revolution speed is 1100 revolutions per minute, the autopropagation speed is 850 revolutions per minute, and the stirring time is 180 s.

[0045] Step 2, adding Sn-3.0Ag-0.5Cu micron powder into Bi 2 Te 3 The mixture of nanoparticles and flux is stirred using a planetary mixer to prepare Bi 2 Te 3 Nanoparticle Reinforced Sn-3.0Ag-0.5Cu Solder Paste. The stirring revolution speed is 850 rpm, the autorotation speed is 850 rpm, and the stirring time is 150 s.

[0046] Step 3, using Sn-3.0Ag-0.5Cu solder paste to form solder joints through a reflow soldering process. The welding peak temperature is 240 ℃, and the time above the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com