Electrode for cold cathode fluorescent tube

A cold cathode and fluorescence technology, applied in the field of electrodes, can solve the problems of high unit price of materials, increase the cost of finished products, low toughness, etc., and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

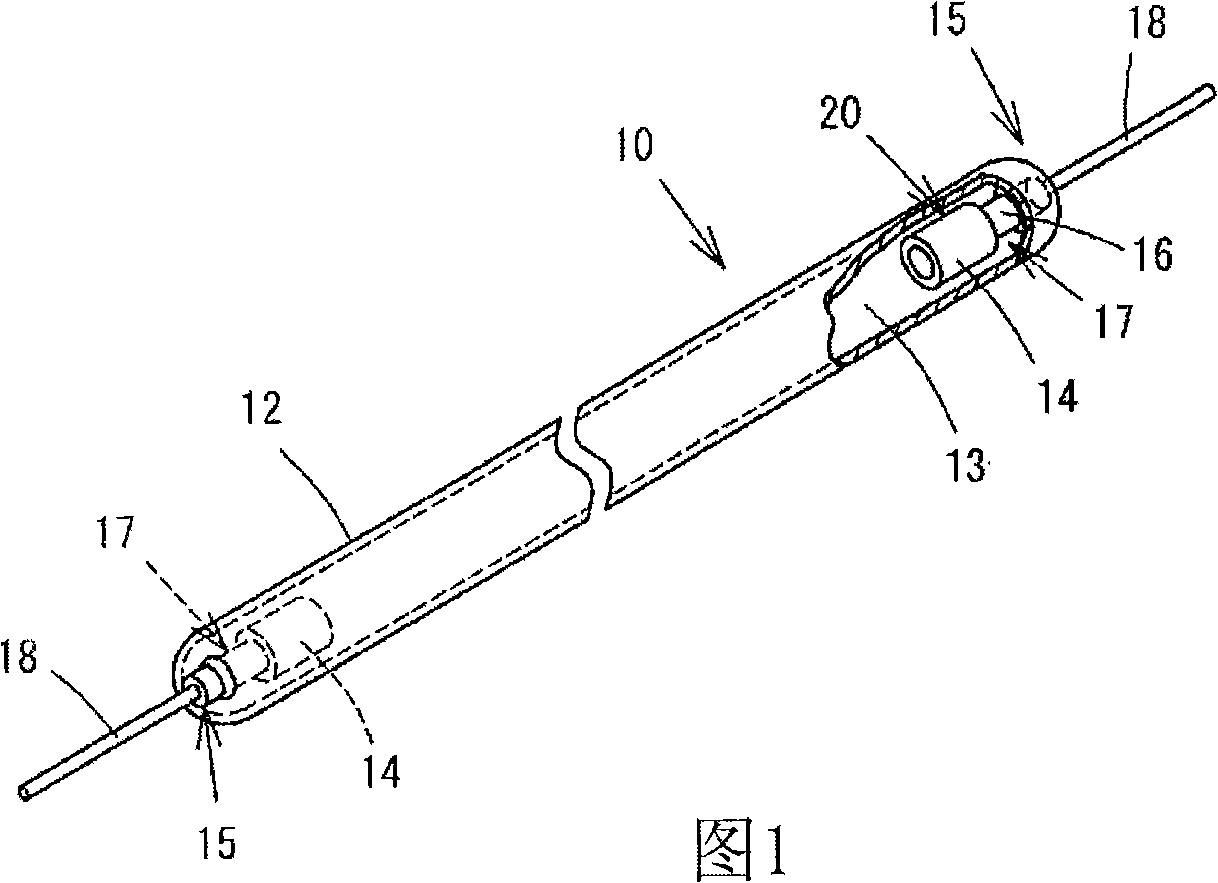

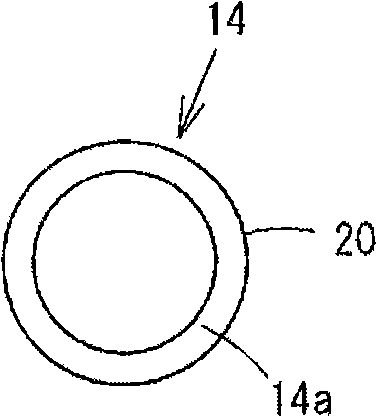

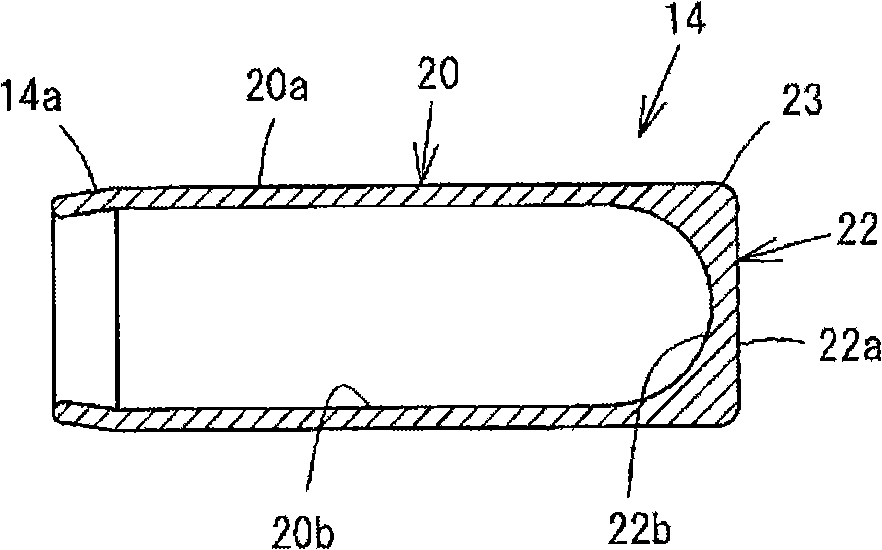

[0045]An electrode for a cold cathode fluorescent tube and a cold cathode fluorescent tube using the electrode in a first embodiment of the present invention will be described below with reference to FIGS. 1 to 5. FIG. First, the cold cathode fluorescent tube 10 shown in FIG. 1 is equipped with a glass tube 12, a phosphor layer 13, an electrode 14, and a lead member 15, wherein the outer diameter of the glass tube 12 is a cylindrical elongated tube of several mm. , the interior of the sealed two ends is formed as a space in a closed state. A rare gas such as argon, xenon, neon, etc., and a rare gas mixed with mercury vapor in a desired ratio are injected into the closed space. The pressure in the glass tube 12 is set to a pressure of about 0.1 atmospheric pressure which is lower than the atmospheric pressure.

[0046] The glass tube 12 may be formed using, for example, lead glass, soda glass, or low-lead glass, in addition to boron or silicic acid glass. If this cold cathode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com