Machined part cleaning device

A technology for cleaning devices and parts, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

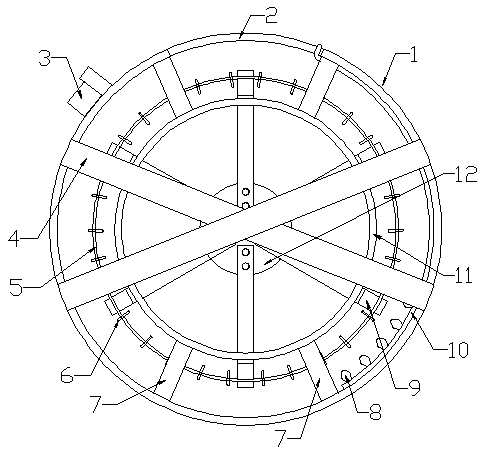

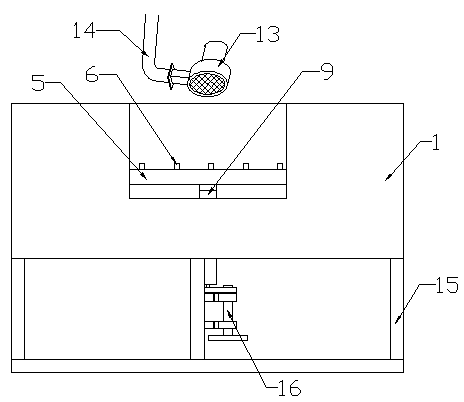

[0020] The cleaning device for machined parts of the present invention is a mechanical device for cleaning parts after machining, and its structure includes a chassis 15 and a housing 1 arranged on the chassis 15, the housing 1 is cylindrical, A cover is provided on the upper mouth of the casing 1 . To facilitate the movement of the cleaning device, casters are provided on the corners of the bottom frame 15 .

[0021] Several stations 6 are arranged in the casing 1, and the stations 6 are used for fixing parts placed thereon. The housing 1 is provided with a rotating system, and the station 6 is arranged on the rotating system along the circumferential direction, and can follow the rotating system to rotate along the circumferential direction. The rotation system includes a disc-shaped turntable 12 located in the housing 1. The turntable 12 is arranged at the bottom of the housing 1, and a chain transmission mechanism 16 connected with the turntable 12 is provided under the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com