High-strength high-toughness heat-resistant aluminum-iron alloy and 3D printing method thereof

A high-strength, high-toughness, aluminum alloy technology, applied in the field of 3D printing, can solve the problems of limiting the use range of Al-Si alloy, high temperature performance decline, grain growth and other problems, to improve room temperature and high temperature mechanical properties, improve high temperature performance, Effect of room temperature strength and high temperature strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The composition of a high-strength heat-resistant aluminum-iron alloy includes by mass percentage:

[0034] Fe iron 8.9%, Cr chromium 1.0%, Ta tantalum 0.2%, cerium Ce 0.1%, the rest is Al aluminum and unavoidable impurities.

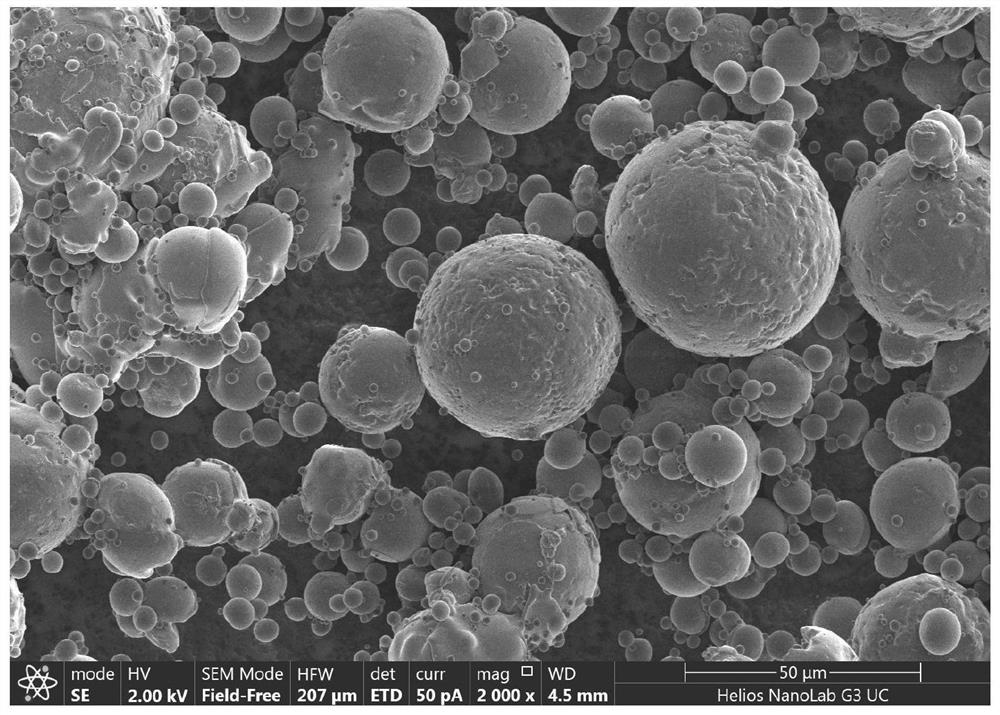

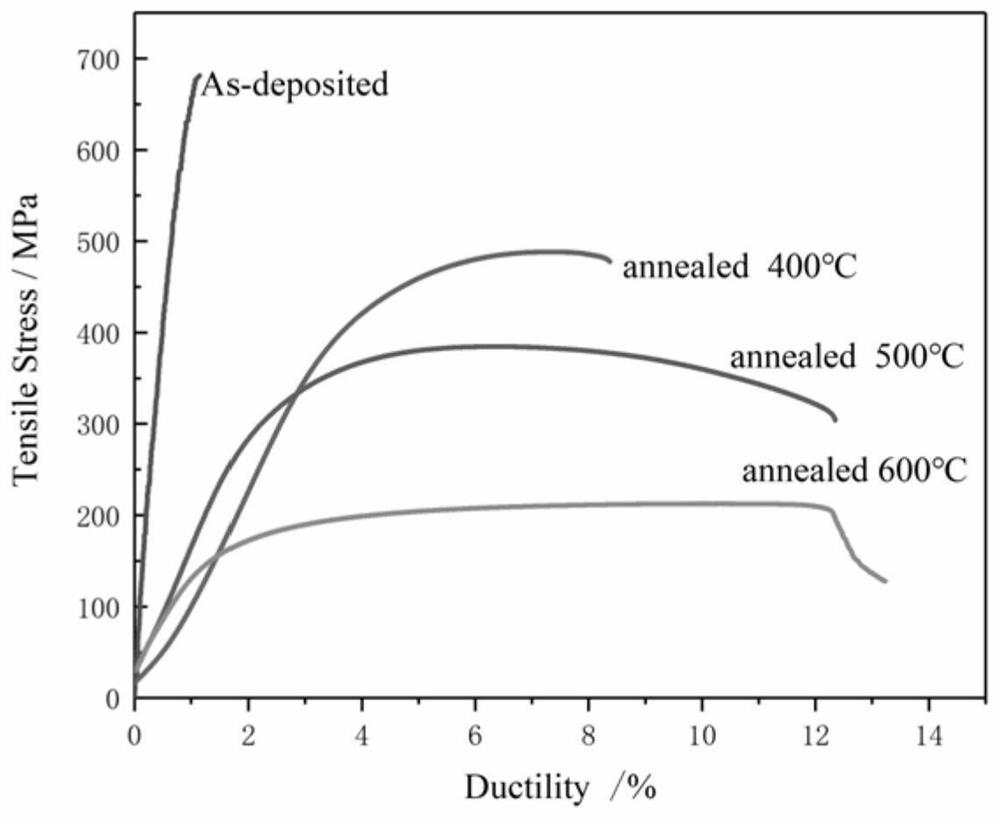

[0035] The above 3D printing heat-resistant aluminum alloy powder, its preparation method is: ultrasonic stirring vacuum melting, using high-purity argon supersonic atomization to make powder, the melting temperature is 850 ℃, the pressure in the melting furnace is 0.8MPa, using high-purity argon Supersonic gas atomization of metal droplets as a medium can obtain more than 95% spherical or spherical powder. The high-iron aluminum alloy is prepared by the selective laser melting method, the powder particle size range is 15-53μm, and the corresponding process parameters are: The scanning distance is 120 μm, the powder coating thickness is 30 μm, and the scanning strategy is checkerboard scanning. The printed samples were subjected to stress-relie...

Embodiment 2

[0037] The composition of a high-strength heat-resistant aluminum-iron alloy includes by mass percentage:

[0038] Fe iron 8.5%, Cr chromium 2.0%, Ta tantalum 0.2%, niobium 0.2%, cerium Ce 0.12%, erbium Er 0.08%, the rest is Al aluminum and unavoidable impurities.

[0039]The above 3D printing heat-resistant aluminum alloy powder, its preparation method is: ultrasonic stirring vacuum melting, using high-purity argon supersonic atomization to make powder, the melting temperature is 850 ℃, the pressure in the melting furnace is 0.8MPa, using high-purity argon Supersonic gas atomization of metal droplets as a medium can obtain more than 95% spherical or spherical powder. The high-iron aluminum alloy is prepared by the selective laser melting method, the powder particle size range is 15-53μm, and the corresponding process parameters are: The scanning distance is 120 μm, the powder coating thickness is 30 μm, and the scanning strategy is checkerboard scanning. The printed samples...

Embodiment 3

[0041] The composition of a high-strength heat-resistant aluminum-iron alloy includes by mass percentage:

[0042] Fe iron 8.0%, Cr chromium 1.0%, Ta tantalum 0.2%, cerium Ce 0.12%, holmium Ho 0.2%, the rest is Al aluminum and unavoidable impurities.

[0043] The above 3D printing heat-resistant aluminum alloy powder, its preparation method is: ultrasonic stirring vacuum melting, using high-purity argon supersonic atomization to make powder, the melting temperature is 850 ℃, the pressure in the melting furnace is 0.8MPa, using high-purity argon Supersonic gas atomization of metal droplets as a medium can obtain more than 95% spherical or spherical powder. The high-iron aluminum alloy is prepared by the selective laser melting method, the powder particle size range is 15-53μm, and the corresponding process parameters are: The scanning distance is 120 μm, the powder coating thickness is 30 μm, and the scanning strategy is checkerboard scanning. The printed samples were subject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com