Full-automatic tape-casting machine and techniques for producing piezoelectric electronic ceramics and sheet type electronic ceramics

A tape casting machine, fully automatic technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of low feeding control accuracy of the air pressure pumping system, difficulty in controlling the casting thickness, etc., to achieve easy operation, improve casting accuracy, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

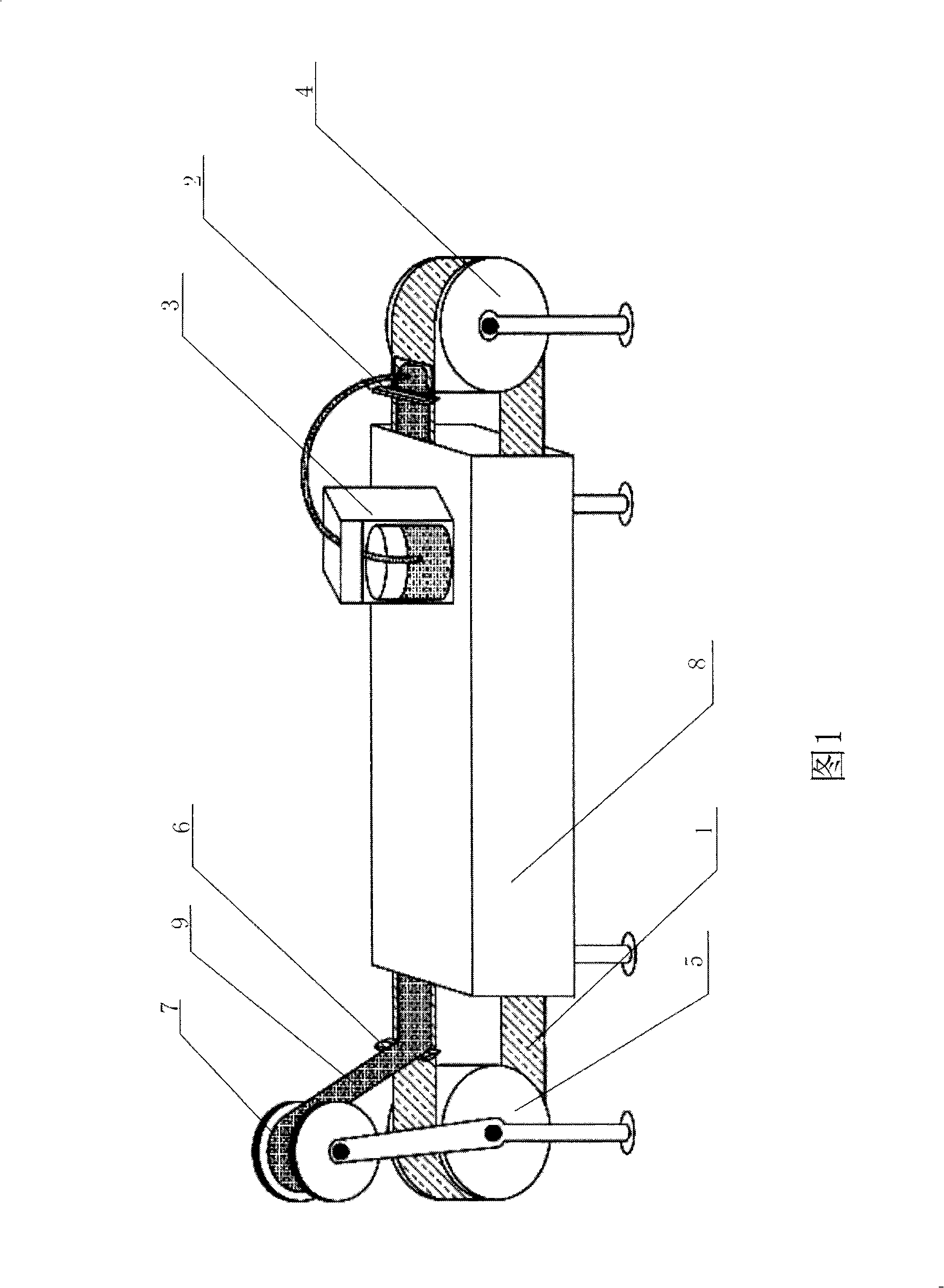

[0019] A fully automatic casting machine of the present invention comprises a steel strip 1, a scraper box 2, an automatic feeding system 3, and rollers 4,5. The steel belt 1 is a closed belt installed between the two rollers 4, 5, the steel belt 1 passes through the inside of the drying tunnel 8 between the two rollers 4, 5, the scraper box 2 and the automatic feeding The system 3 is installed at the end of the driving roller 4, and has a film cutter 6 and a take-up shaft 7 at the end of the passive roller 5.

[0020] The scraper box 2 has an adjusting screw and a micrometer to adjust the distance between the scraper and the steel strip 1 .

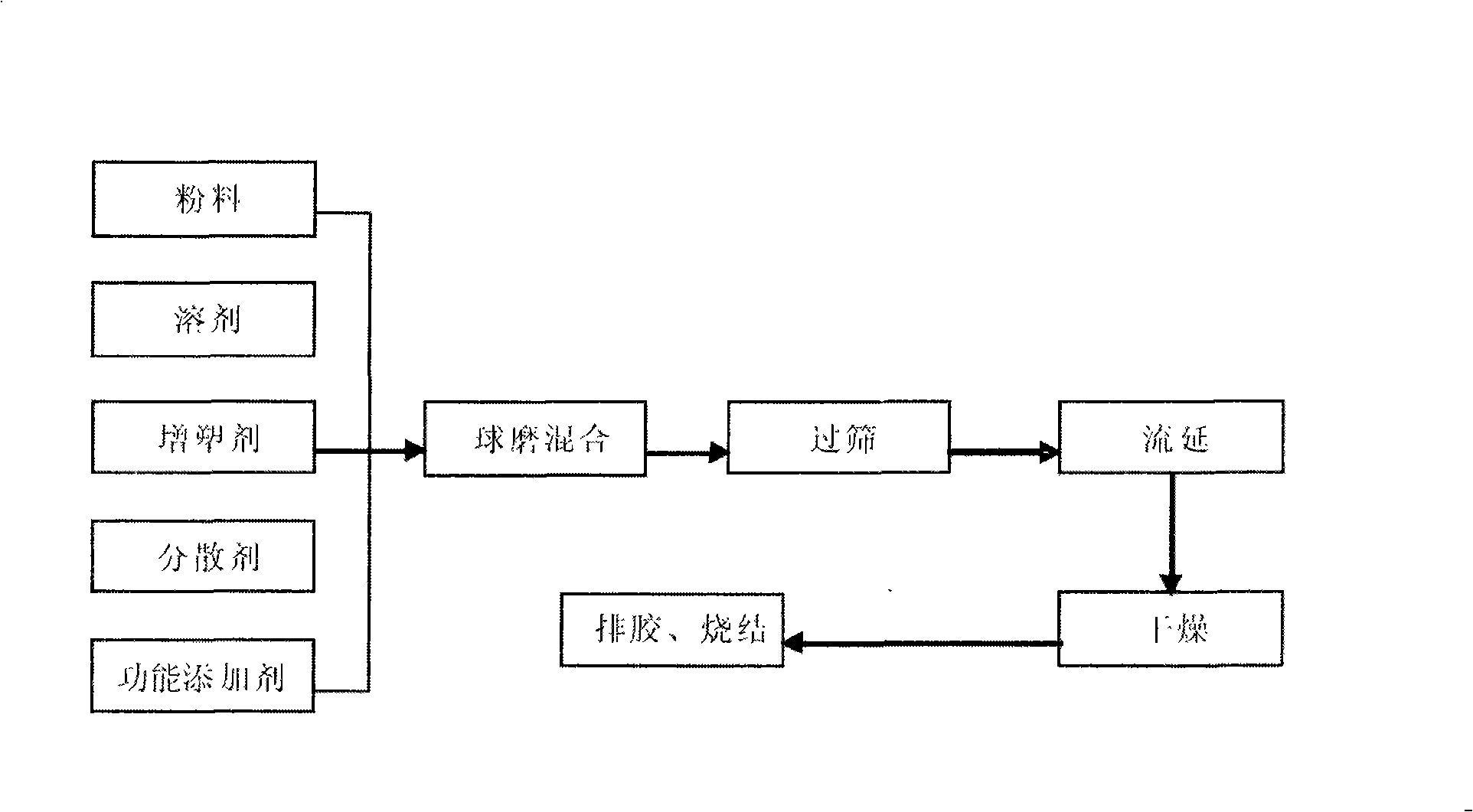

[0021] A kind of technique of full-automatic casting machine of the present invention produces piezoelectric electronic ceramics and chip electronic ceramics, it is characterized in that: this technique comprises the following steps:

[0022] (1) Add binder and solvent to the powder and mix by ball milling;

[0023] (2) The slurry is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com