Top-bottom bidirectional uniform sand ejection casting and modeling device and method for manufacturing sand mold by device

A sand casting and uniform technology, applied in the field of top-bottom two-way uniform sand shooting casting molding device, can solve the problems of low sand shooting efficiency, difficulty in ensuring appearance quality, low sand shooting uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

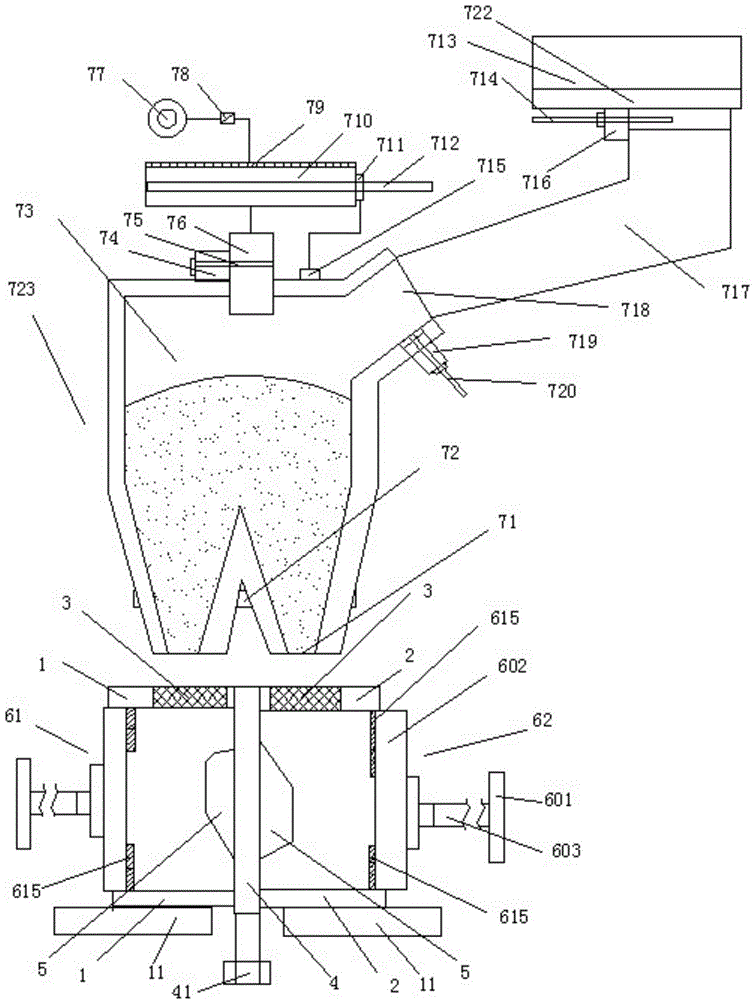

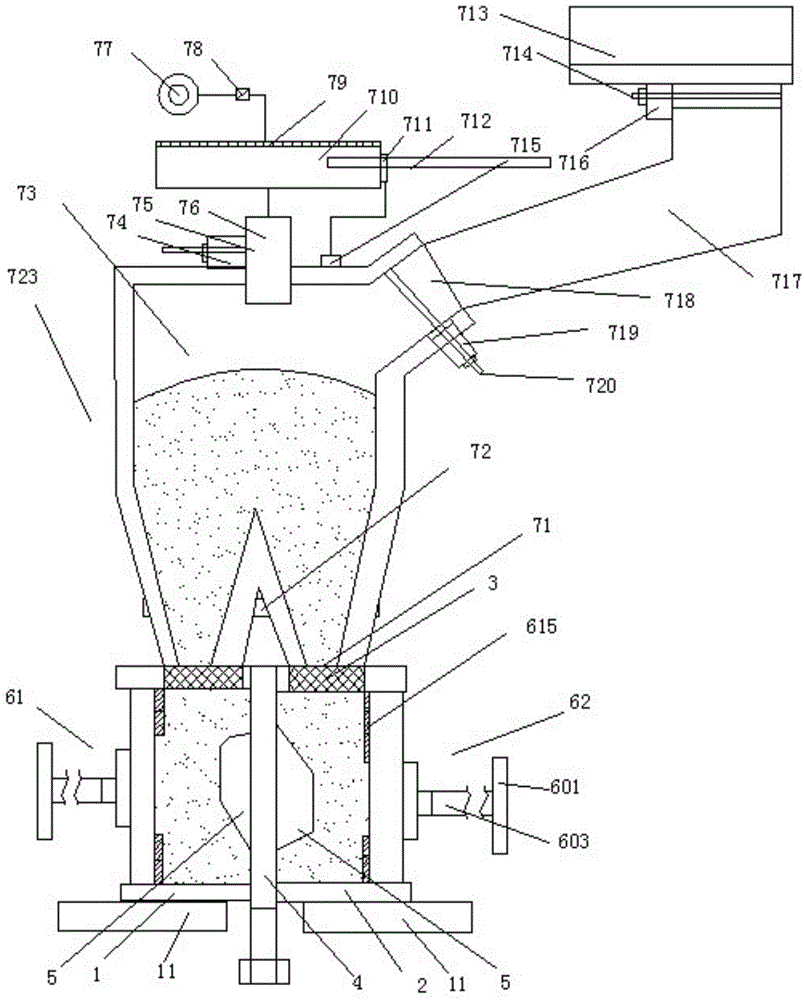

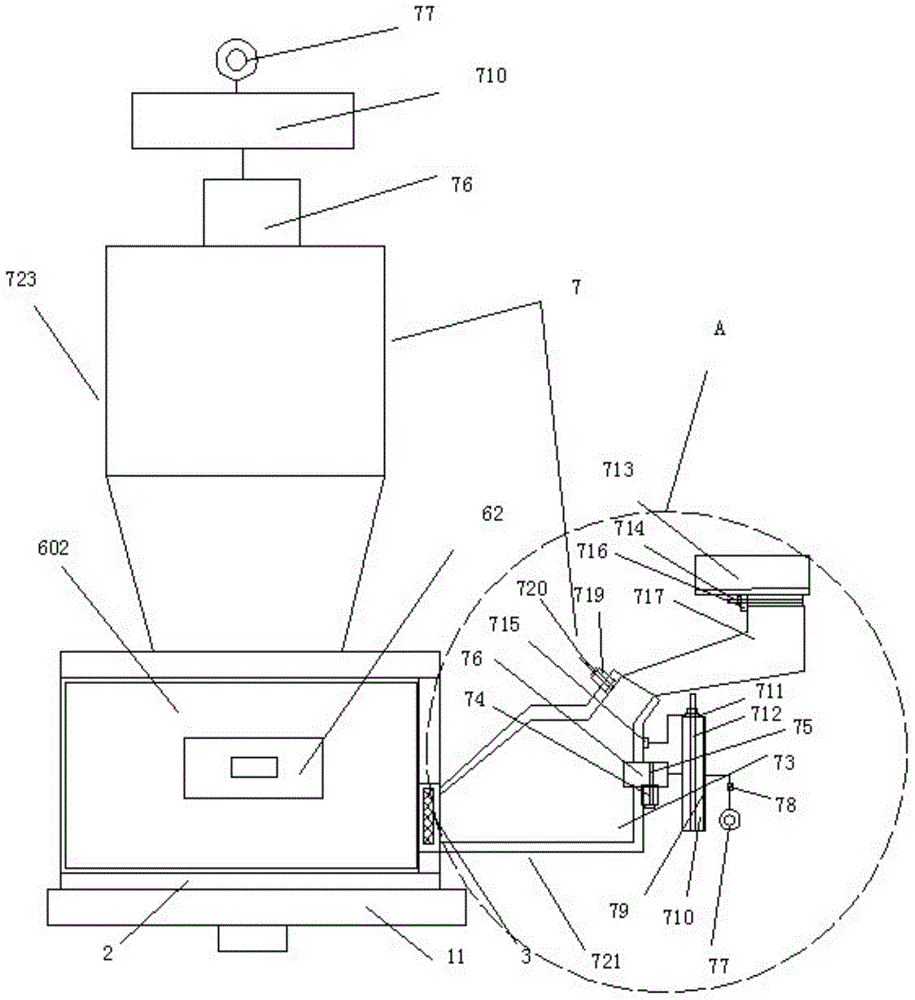

[0076] Example 1. Such as Figure 1 to Figure 4 As shown, the top and bottom two-way uniform sand-shot casting molding device is characterized in that: the molding device includes:

[0077] A left sand box 1 and a right sand box 2, the left sand box 1 and the right sand box 2 are box structures with open front and rear sides; the upper sides of the left sand box 1 and the right sand box 2 The square holes of the sand shooting boards and the right sides are all provided with the sand shooting board square holes, and the sand shooting board 3 is installed on the square holes of the sand shooting boards; the bottom surface of the sand shooting board 3 is a curved surface. The sand-shooting board 3 is provided with several square holes 91 with quadrilateral cross-sections. The square holes are respectively perpendicular to the bottom surface where the holes are located. Such as Figure 18 As shown, an opening and closing device is provided on the sand shooting board 3, and the...

Embodiment 2

[0087] Example 2. The only difference between this embodiment and embodiment 1 is: as Figure 5 , Figure 6 As shown, the dense adjustment device includes an elastic adjustment plate, and the elastic adjustment plate 616 is arranged on the side of the extrusion plate 602 close to the model 5 and has the same size as the side of the extrusion plate 602; The board is made of 50-70% polyester, 10-20% isocyanate, 10-20% polyol, etc. by hot pressing. The elastic regulating plate 616 can fine-tune the compactness of the molding sand.

Embodiment 3

[0088] Example 3. such as 7 to figure 1 As shown, as shown, the extruded plate is provided with a partition 604, and the partition 604 is perpendicular to the bottom surface of the extruded plate 602; the inner surface and the outer surface of the partition 604 are horizontally provided with several horizontal plates 608, and the partition The inner and outer surfaces of 604 are vertically provided with several vertical plates 609, and the horizontal plates and vertical plates cross each other to form several grids 611; the centroid of each grid 611 on the partition 604 is provided with a hole 610, and the inside of the hole 610 is horizontal. A connecting rod 606 is installed; the grille 611 on the outer side of the partition 604 is provided with a pressing plate 607 adapted to its shape, and the grille on the inner side of the partition is provided with a push plate 605 adapted to its shape. The plates 605 are connected by connecting rods 606; a cavity 612 is provided betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com