Manufacturing process of robot joints

A technology of robot joints and manufacturing processes, applied in the direction of manufacturing tools, manipulators, joints, etc., to improve labor production levels, increase rigidity, and solve the effects of loose thermal nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A manufacturing process of a robot joint, including the following manufacturing process steps: a. Material preparation: selecting raw and auxiliary materials for casting, melting in an electric furnace, and online monitoring of molten iron composition by a furnace thermal analyzer and a spectrometer;

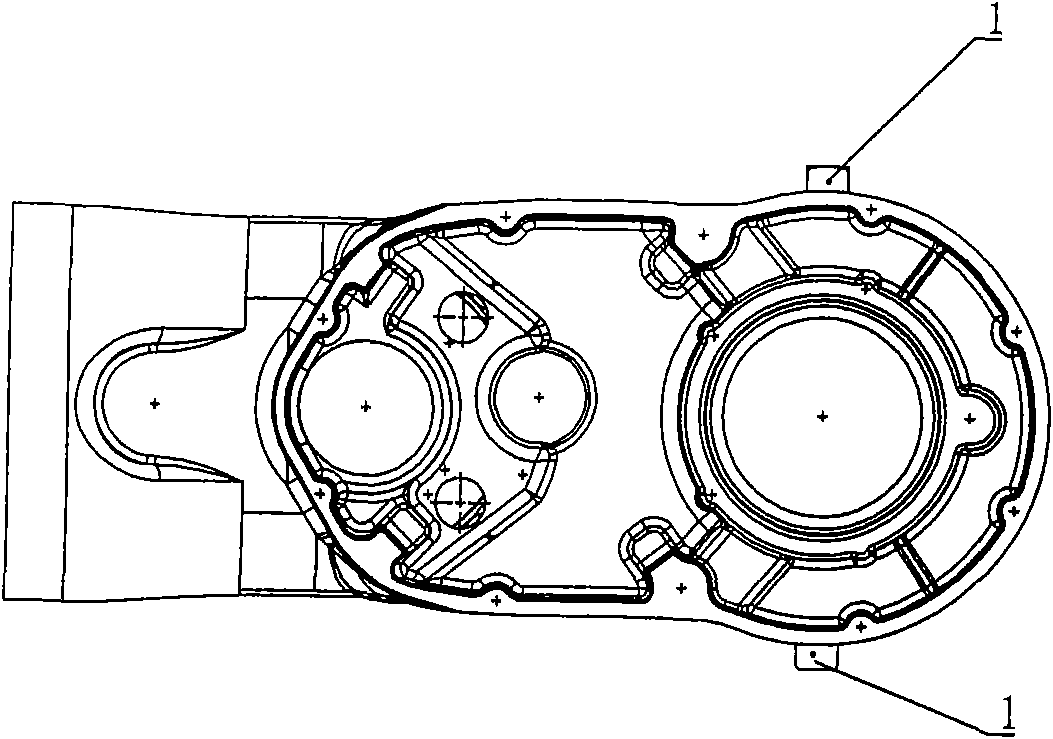

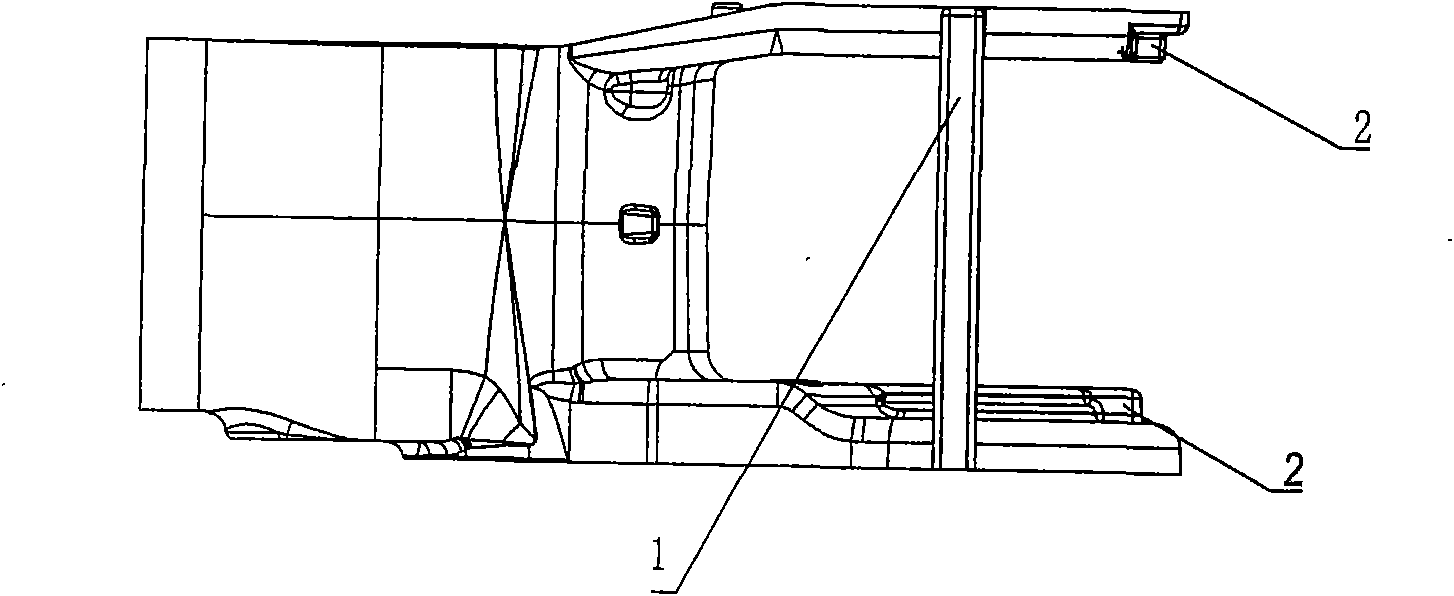

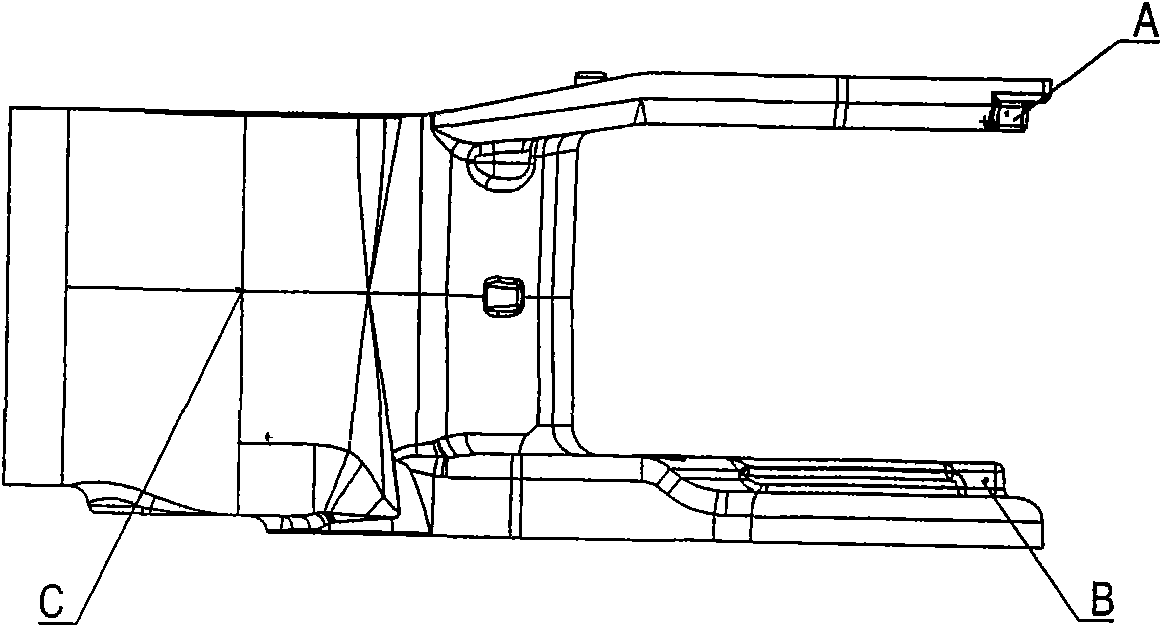

[0016] b. Casting of robot joint castings: adopt the external hot-shooting core expansion process, and inlay and form cold iron on the isolated hot nodes of the castings, and set reinforcing ribs 1 on the suspended two sides of the robot joint castings, such as figure 2 As shown, a process boss 2 is added to the pressing point of machining. After the core is assembled, the pouring, cooling, and sand separation of the casting are realized by the fully automatic horizontal parting molding line, as shown in image 3 As shown, the reinforcing rib 1 of this process is removed with a cutting machine after the casting is tempered (at a temperature of 500°-550°) for 1.5-2 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com