Quartered core device and its application method

A technology of cores and parting surfaces, applied in the direction of cores, molds, mold components, etc., can solve problems such as the complexity of the core removal mechanism, the deformation of the core fork, and the impact on the quality of the inner cavity of the casting and the life of the core. , to avoid deformation, increase surface quality and casting precision, and simplify the operating mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

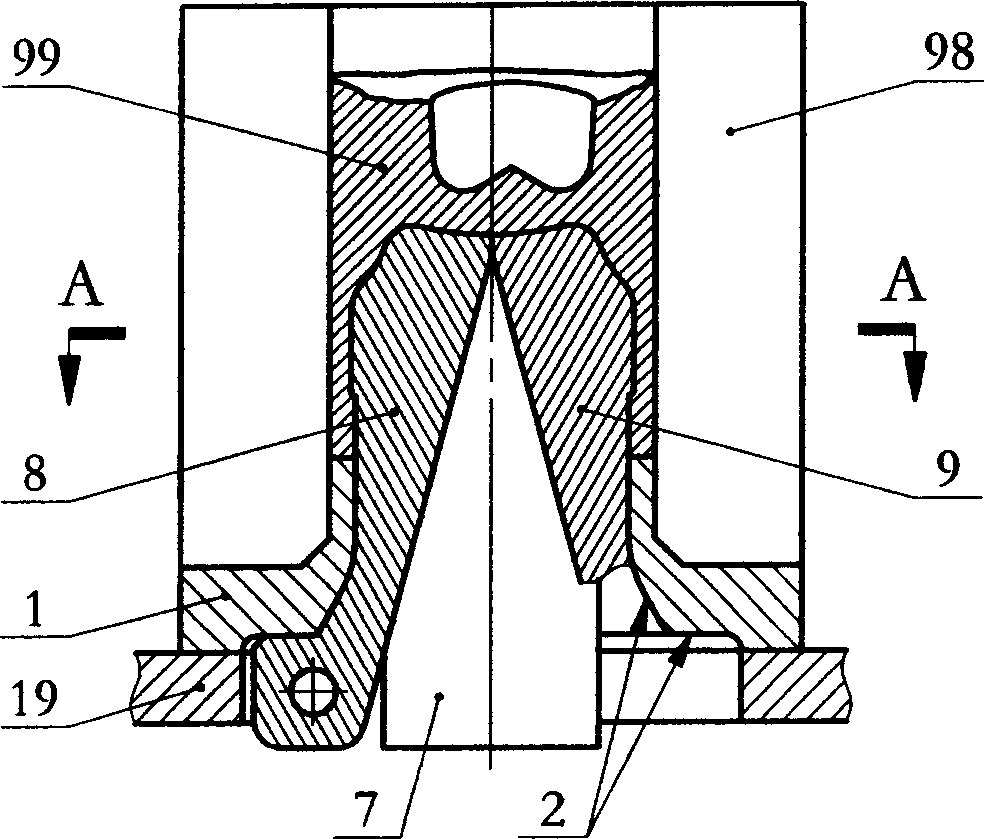

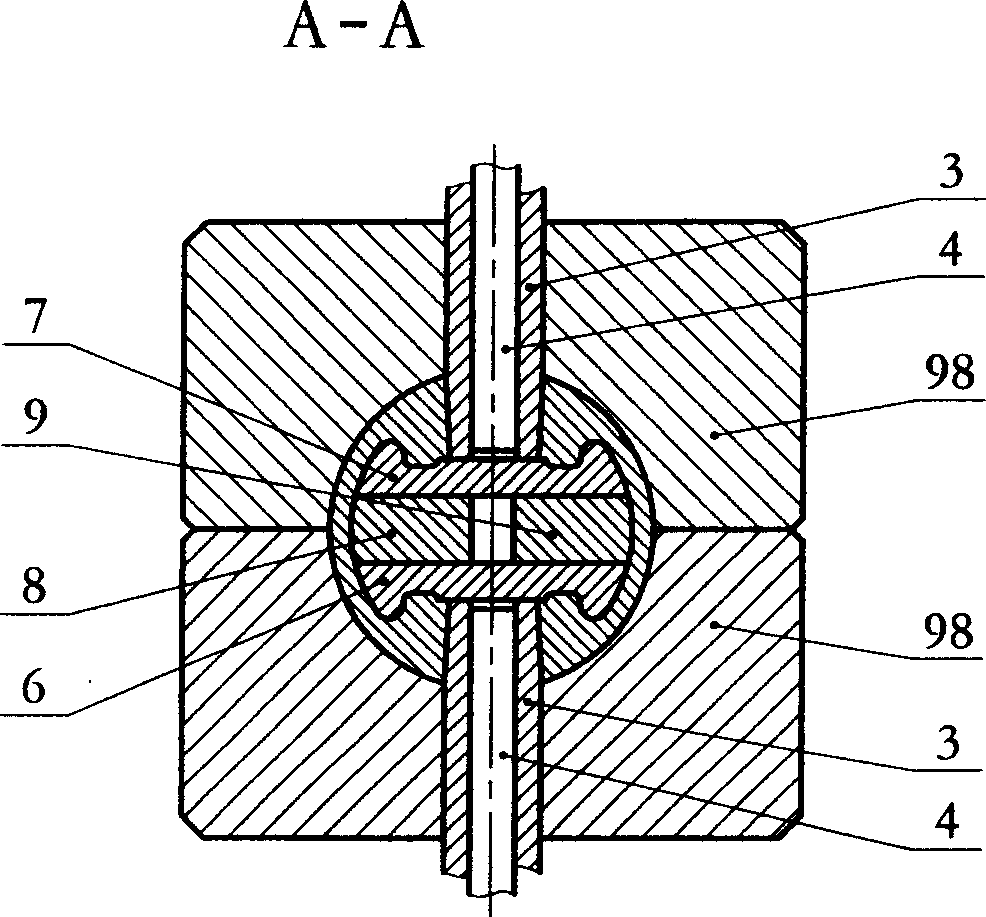

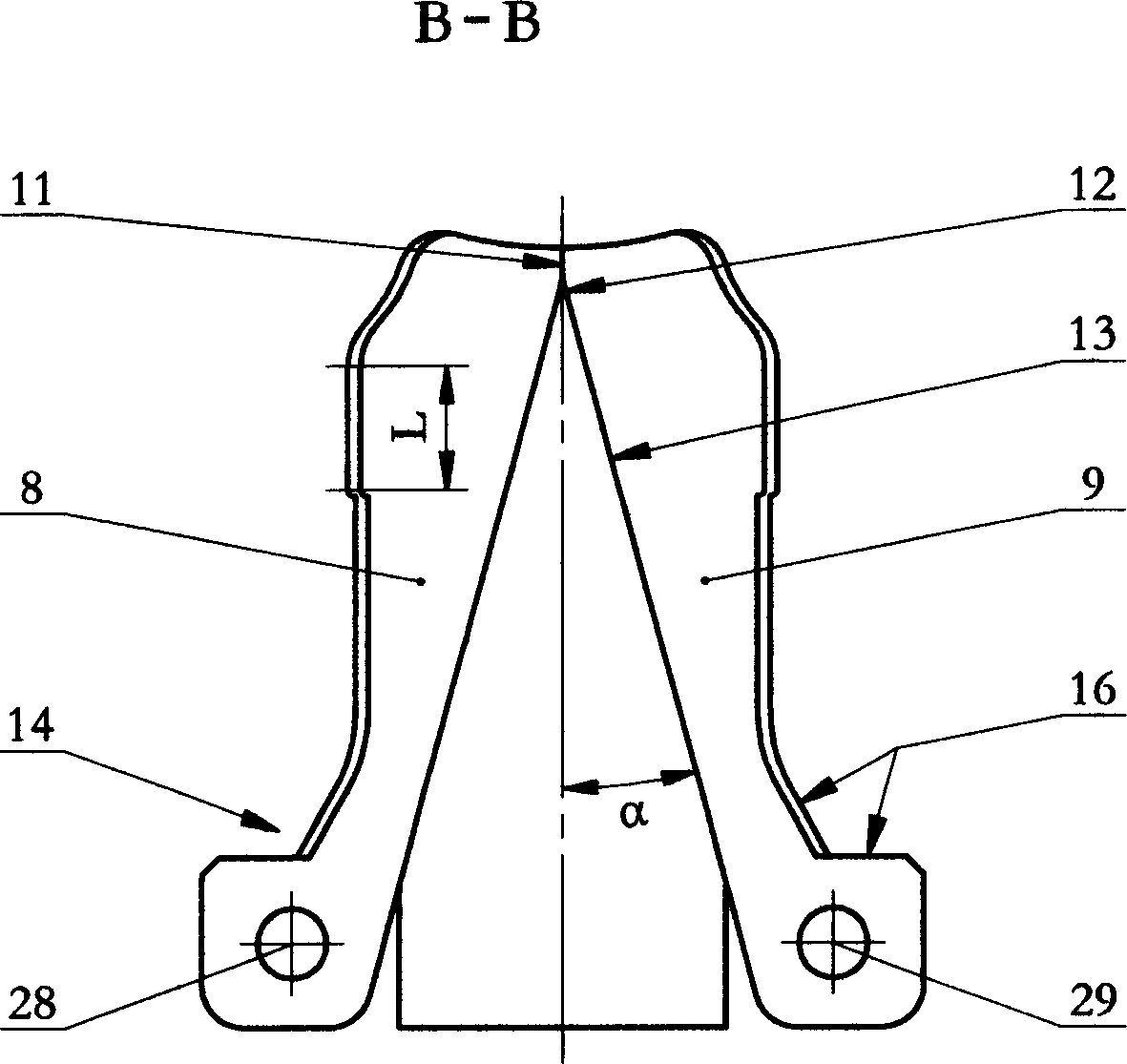

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0054] The embodiment of the present invention is a four-part core system used for casting aluminum pistons with a specification of Φ70-135mm. Due to the adoption of a double casting position design, in addition to the superior performance of the four-part core itself, beams and curved beams are the main components. The operating mechanism of the components has also been optimized for overall performance.

[0055] Such as Figure 1-Figure 4 , the quarter core is composed of a pair of side cores and a pair of center cores. They are side core A6, side core B7, center core A8, and center core B9. Side core A6 and side core B7 are formed by cutting the core axially with two parallel chords; center core A8 and center core B9 It is formed by cutting the core with the center core cutting line. Two points with the shortest distance between the two strings and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com