Multifunctional gearbox drive system

A multi-functional gearbox and transmission system technology, applied in the direction of transmission components, transmission devices, components with teeth, etc., can solve the problems of complicated operation and poor working stability, and achieve the effect of simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

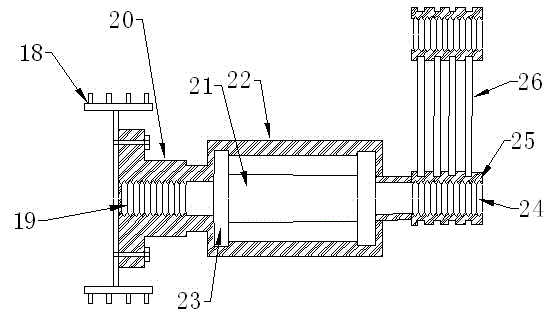

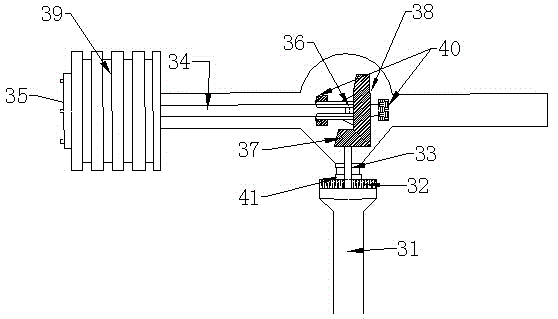

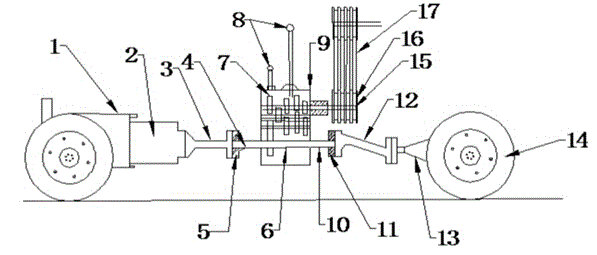

[0014] In an embodiment of the present invention, a multifunctional gearbox transmission system includes a shifting handle 8, a multifunctional gearbox 9, a shaft A6, a transmission shaft and a pulley, the transmission shaft includes a transmission shaft A3 and a transmission shaft B12, and the pulley includes a pulley A16 It is connected with the pulley D45, the engine 1 is connected with the front tire of the tire 14, the other end of the engine 1 is connected with the driving gearbox 2, and the driving gearbox 2 is connected with the shaft end A4 of the shaft A6 through the transmission shaft A3, between the transmission shaft A3 and the shaft end A4 Also be provided with transmission joint plate A5, axle A6 is installed in the bottom of multifunctional gearbox 9, the shaft end B10 of axle A6 is by connecting transmission shaft B12, and transmission shaft B12 is connected the rear tire of tire 14 by rear axle 13, multifunctional gearbox 9 Gearbox internal gear 7 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com