Transformation impact case-free tightly molding device and method for molding by using same

A compact and mold-forming technology, applied in casting molding equipment, metal processing equipment, molding machines, etc., can solve the problems of low sand shooting efficiency, difficulty in ensuring appearance quality, poor consistency of sand mold hardness on the surface of the inner cavity of the mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

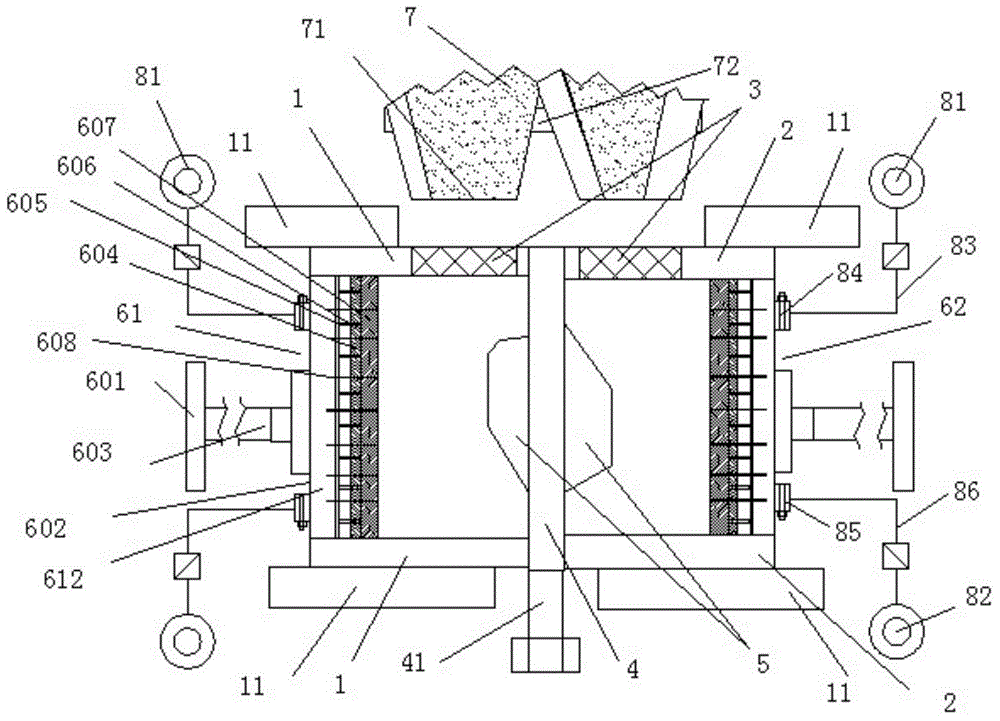

[0090] Example 1. like figure 1 , Image 6 , Figure 30 As shown, a pressure-changing impact boxless compact molding device, including:

[0091] A left sand box 1 and a right sand box 2, the left sand box 1 and the right sand box 2 are box structures with open front and rear sides; the upper sides of the left sand box 1 and the right sand box 2 Sand guide plates 3 are all provided.

[0092] A replaceable double-sided template 4, the double-sided template is installed on the double-sided template mobile replacement device 41, the double-sided template 4 is located between the left sand box 1 and the right sand box 2 and is kept vertical to the ground, and the double-sided template 4 has The left surface corresponding to the rear side of the left sand box 1 and the right surface corresponding to the front side of the right sand box 2; the left surface and the right surface of the double-sided template 4 are respectively provided with a model 5 .

[0093] A sand box moving d...

Embodiment 2

[0111] Example 2. The difference between this embodiment and Embodiment 1 is that the pressure supply device includes a high-pressure gas source 81; the high-pressure gas source 81 is connected to the cavity 612 of the extrusion plate 602 through a pipeline 83, and a controller 84 is provided on the pipeline 83 ; The front side of the squeeze plate 602 and each push plate 605 are provided with some tension springs 613, before the cavity 612 of the squeeze plate 602 is injected with high-pressure gas, under the effect of the tension spring 613, the pressure plate 607 The front side of the front side is in close contact with the rear side of the partition 604; the extruding plate 602 is provided with a vent valve 614 that can release the gas in the cavity 612.

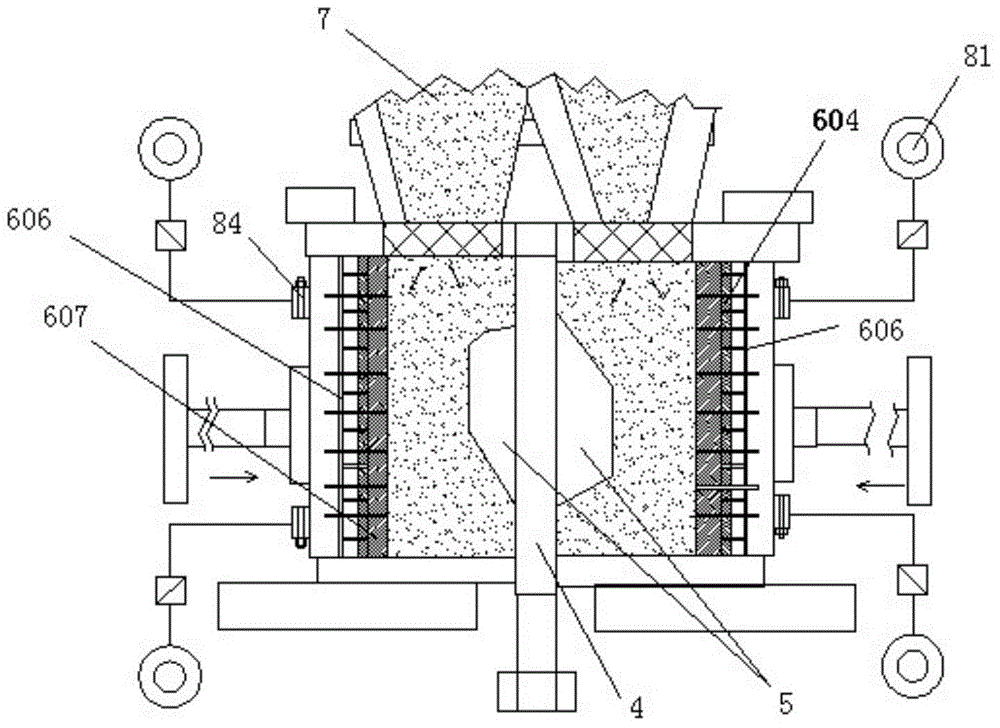

[0112] like Figures 17 to 21 As shown, the method for molding using the above-mentioned variable pressure impact boxless compact molding device includes the following steps:

[0113] Step 1: Place the model on the dou...

Embodiment 3

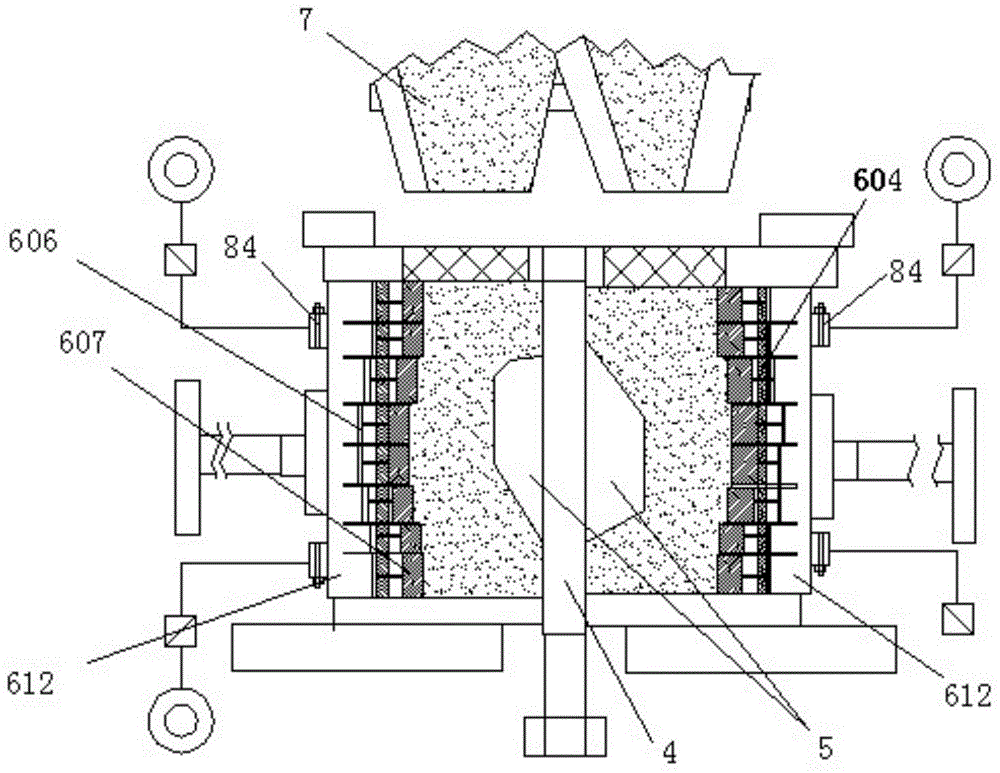

[0123] Example 3. The difference between this embodiment and Embodiment 2 is that the tension of the tension spring 613 is different, the farther the distance from the center of the model 5 is, the looser the tension spring is.

[0124] like Figure 22 to Figure 27 As shown, the method for molding using the above-mentioned variable pressure impact boxless compact molding device includes the following steps:

[0125] Step 1: Place the model on the double-sided template 4; move the double-sided template 4 between the left sand box 1 and the right sand box 2 through the double-sided template moving replacement device 41 and keep it perpendicular to the ground; use the sandbox moving device 11 Both the left sand box 1 and the right sand box 2 or one of them move relatively, clamp the double-sided template 4, insert the left horizontal extrusion device 61 into the left sand box 1 from the front side of the left sand box 1, and press the right horizontal extrusion device 61 into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com