Forward skewed multi-blade impeller with narrow cavity and integral casting technique thereof

An integral casting, multi-wing technology, used in non-variable volume pumps, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve the problem that the noise index cannot meet the needs of fan development, noise control The problem of limited means is to achieve the effect of simple control means, light weight and high casting precision for air noise and vibration acceleration level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

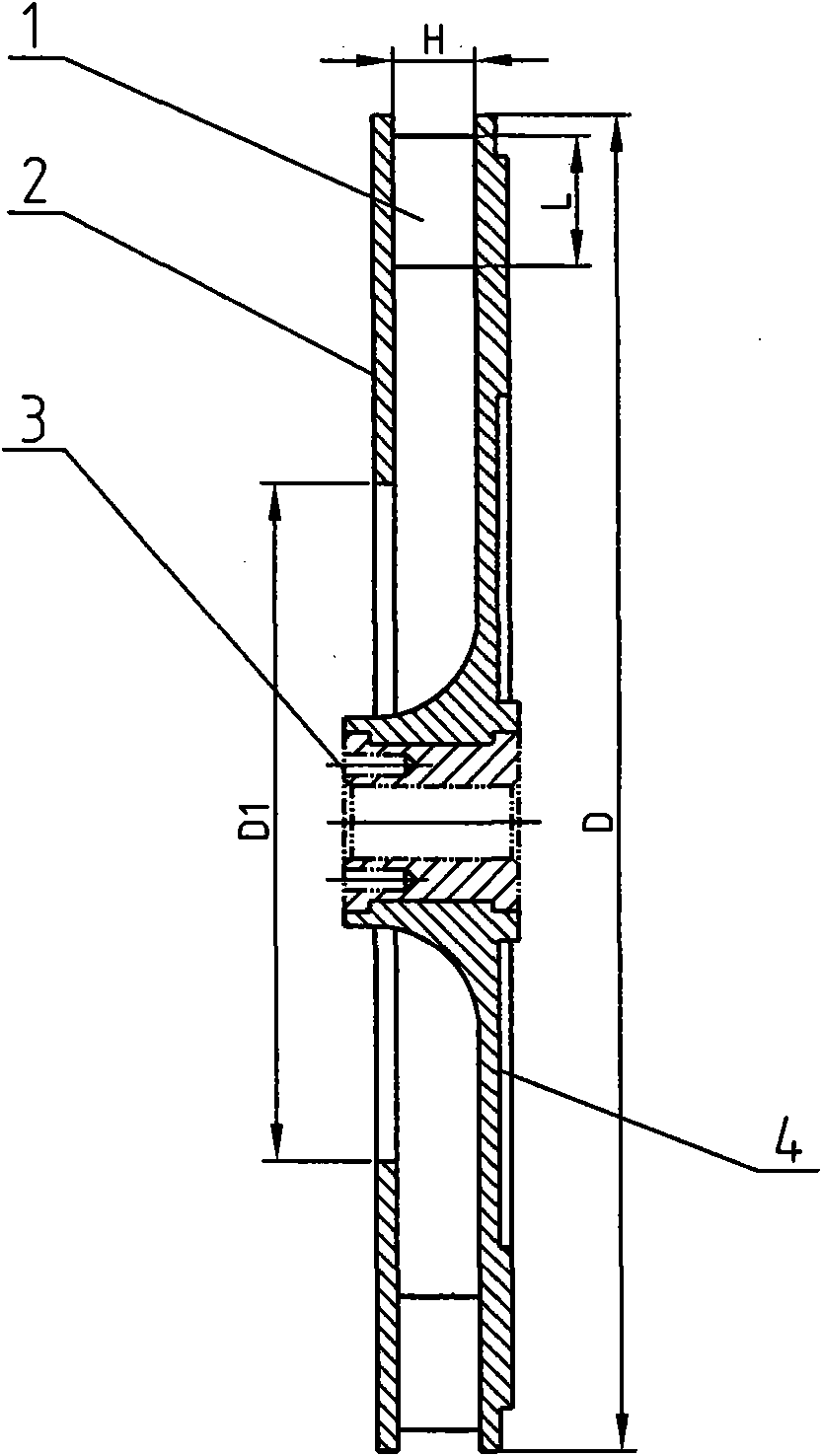

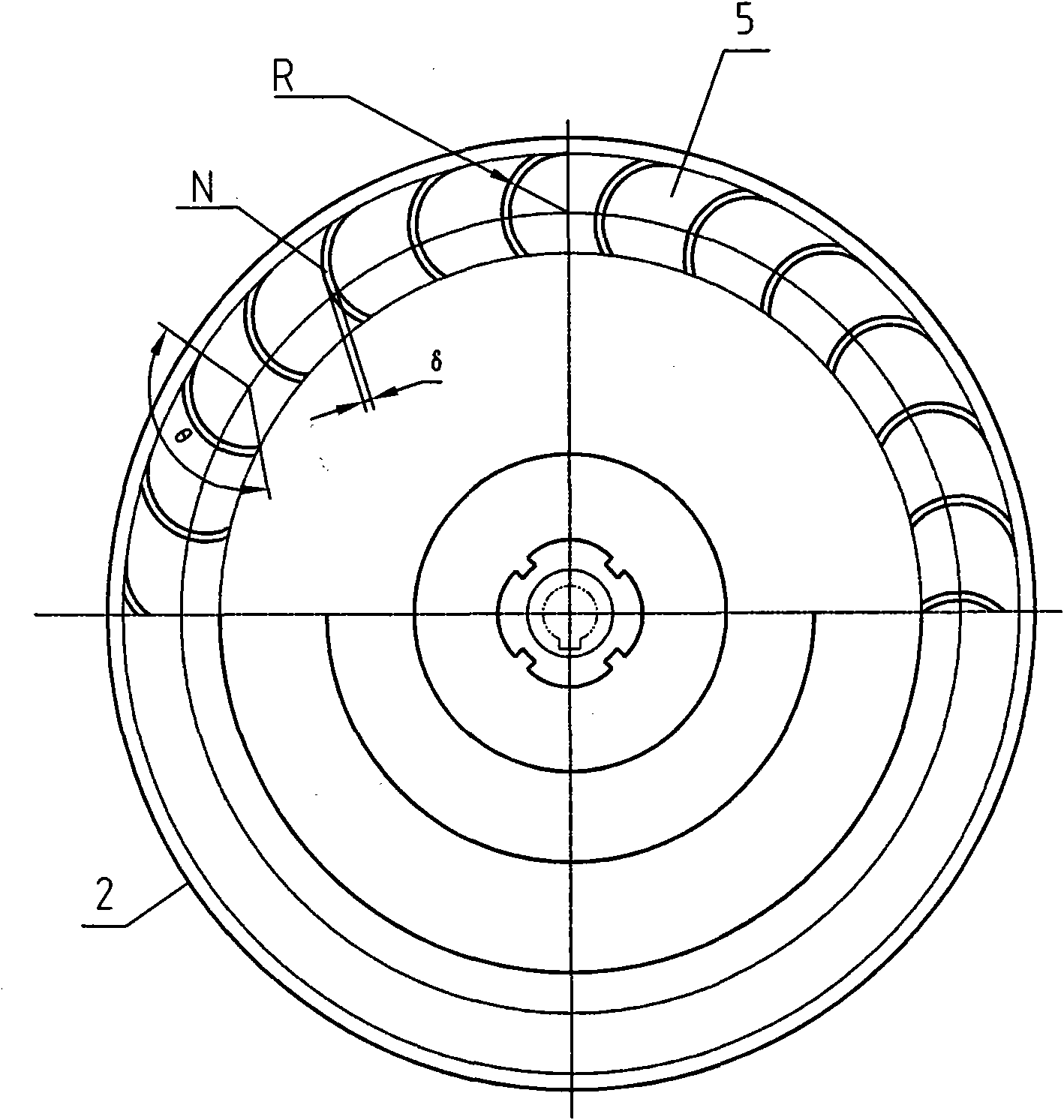

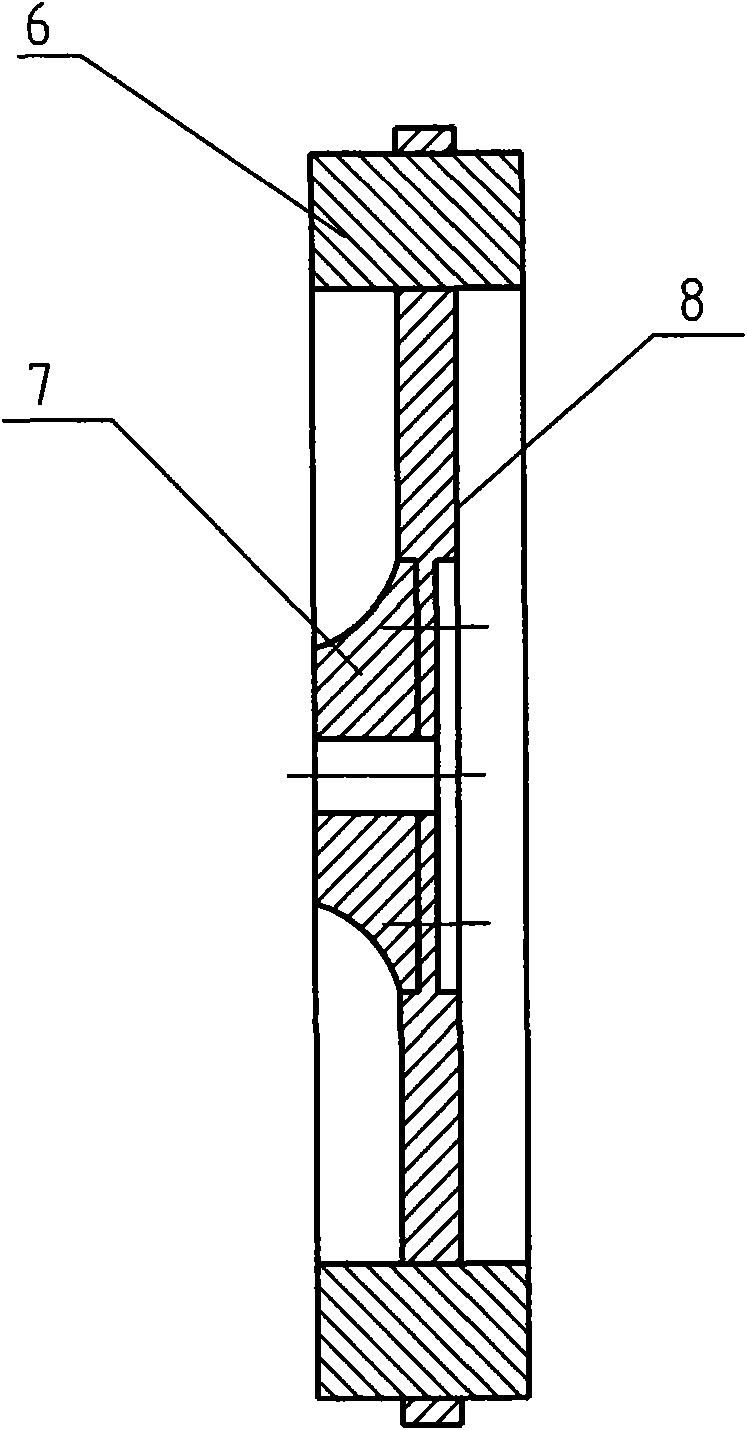

[0027] The structure of forward multi-blade narrow cavity impeller of the present invention is as figure 1 , 2 As shown, it includes a base plate 4 and a hollow front plate 2. The outer diameter D of the base plate is 235mm, and a narrow blade 1 is arranged circumferentially between the base plate and the front plate. The blades are arc-shaped, and the radian θ 2Л / 3, the radius of curvature R is 15mm, the blade radial length L is 28mm, the outlet height H of the blade meridian surface is 16mm, the blade thickness δ is 2mm, 26 blades are evenly distributed along the circumference, and each blade is evenly spaced to form a narrow cavity 5 , the other side of the blade is connected with the front disk, the front disk is hollow and ring-shaped, the outer diameter is the same as that of the base disk, and an air inlet hole is set in the middle, and the diameter D1 of the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com