Manufacturing method of centrifugal pump induction wheel

A manufacturing method and induction wheel technology, applied in the direction of manufacturing tools, casting equipment, casting molding equipment, etc., can solve the problems of many surface defects, poor casting precision, and low quality of finished products, and achieve high fire resistance, long service life, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

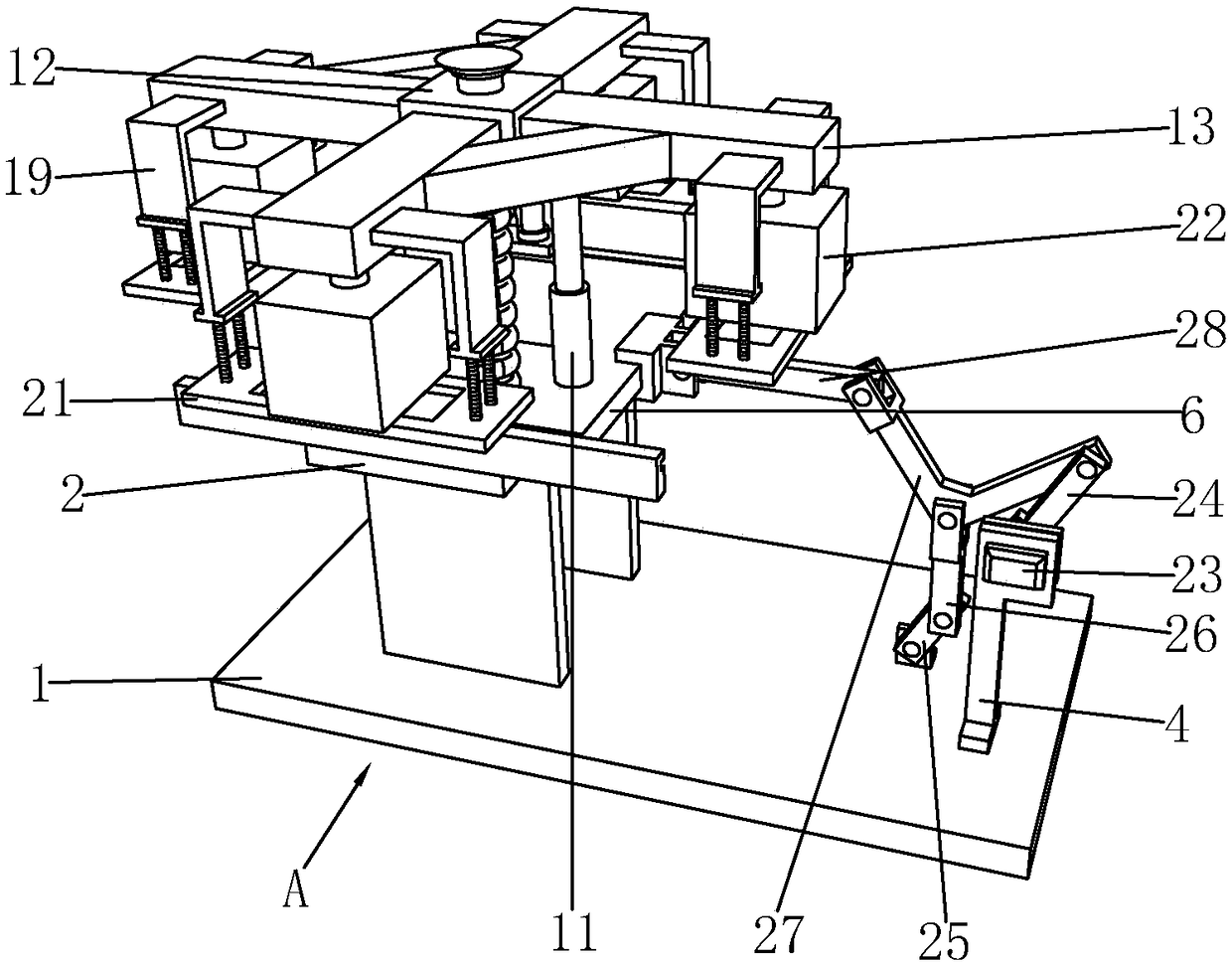

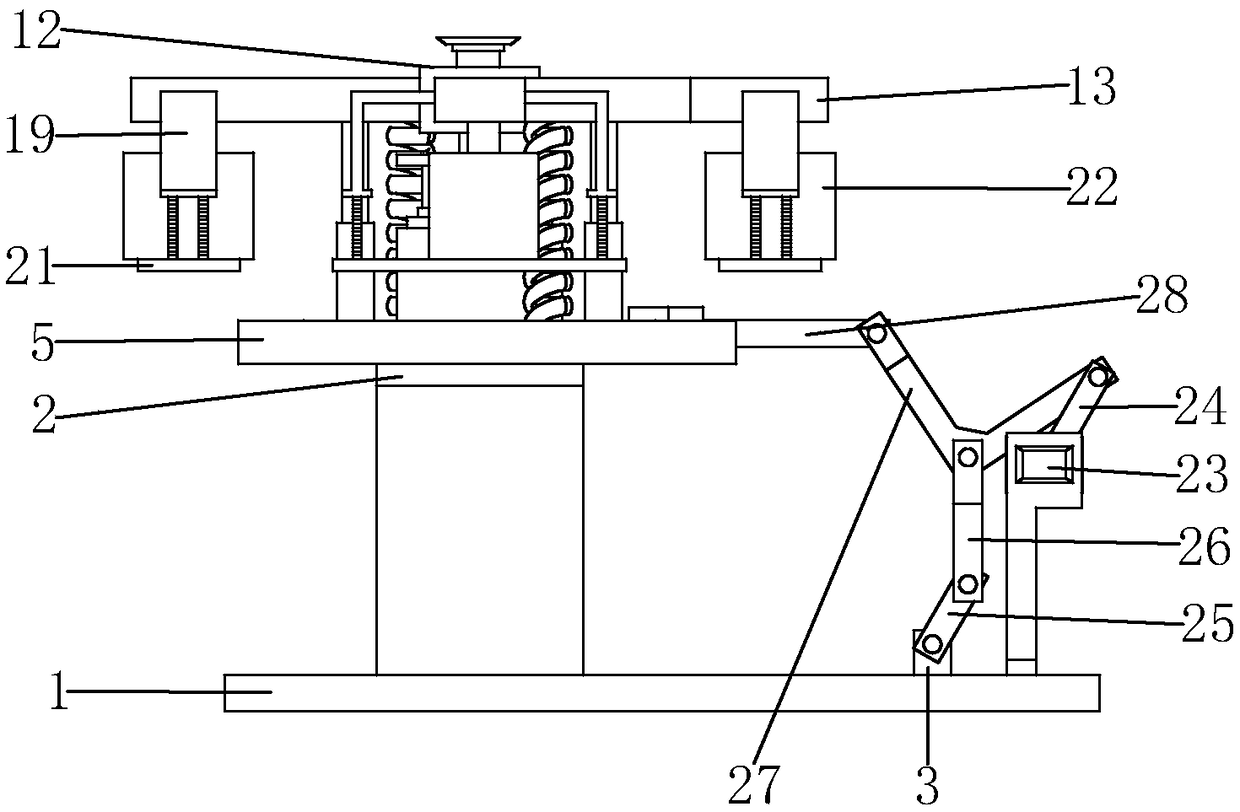

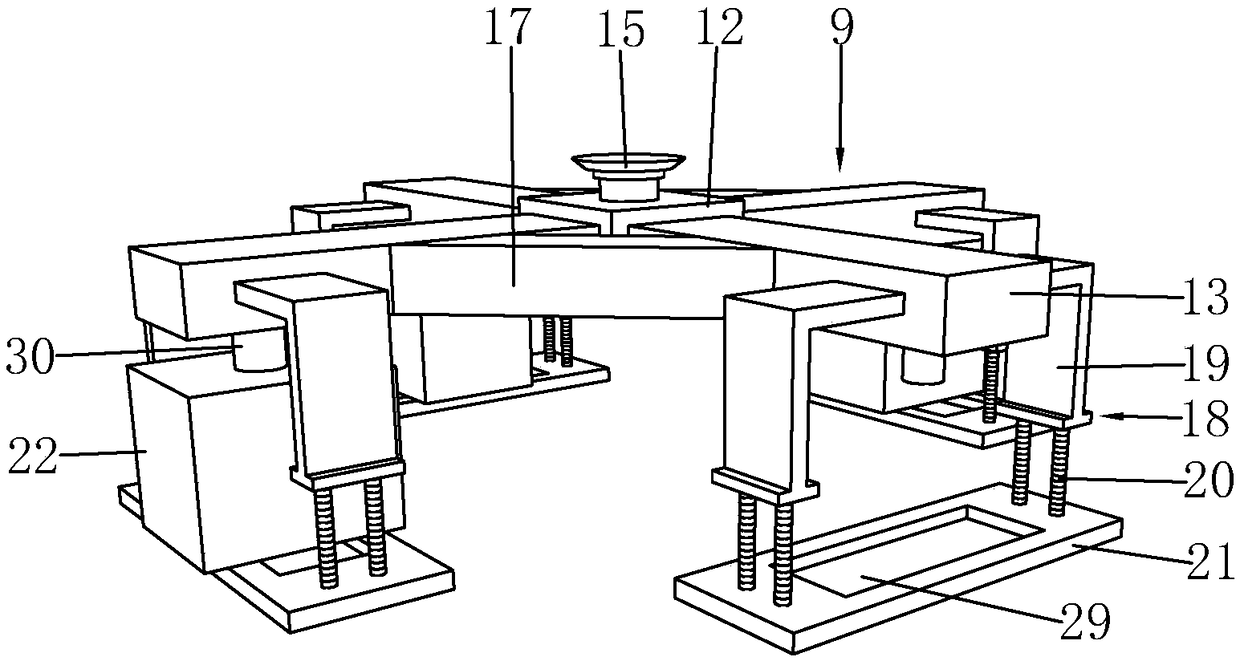

[0034] Such as Figure 1 to Figure 5 Shown, be the manufacture method of a kind of centrifugal pump inducer of the present invention, comprise the steps:

[0035] (a) Form shell manufacturing: Make a wax film according to the three-dimensional shape of the product, apply the refractory slurry evenly on the wax film, and form a ceramic layer on the surface of the wax film. The refractory slurry is made by mixing silica, water and binder Cheng, low cost, high fire resistance. Repeated application of slurry can increase the thickness of the ceramic layer to ensure sufficient refractory performance. Carry out drying at normal temperature then, add the dewaxing liquid of temperature 90~95 ℃ in the pouring port of the ceramic wax film after hardening and carry out dewaxing, the composition of dewaxing liquid is 4~6% ammonium chloride solution, and dewaxing time is 20 to 30 minutes, to ensure sufficient dewaxing time, to avoid wax remaining on the inner cavity wall of the mold shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com