Flexibility-enhanced polyurethane

A technology of softness and polyurethane prepolymer, which is applied in the field of polyurethane industry, can solve the problems of toughness, elasticity, heat resistance, poor adhesion and wear resistance, unsatisfactory gloss and fullness, and high viscosity of ionic liquids. , to achieve strong lipophilic performance, overcome shedding and cracking, and achieve the effect of large molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in combination with specific embodiments.

[0026] The invention provides a kind of polyurethane that strengthens softness, and its preparation method comprises the following reaction steps:

[0027] Step 1: preparation of an ionic liquid polymer with two hydroxyl groups;

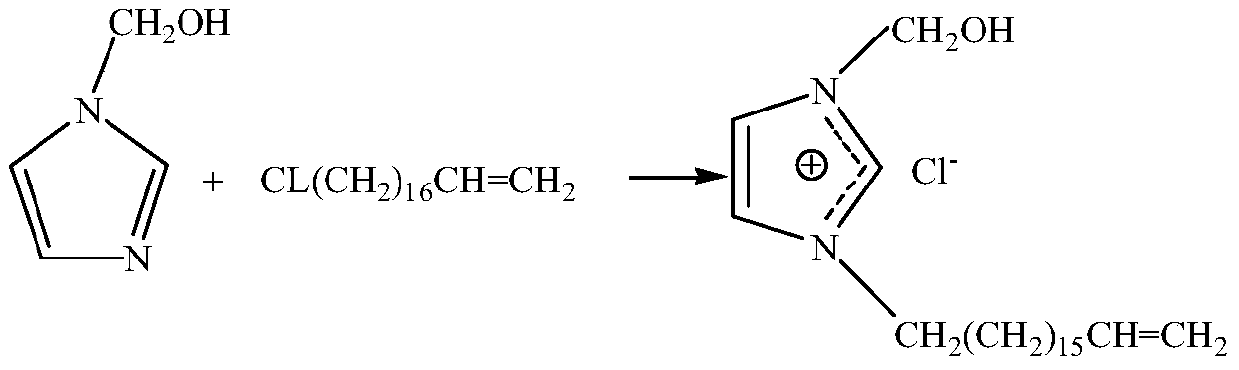

[0028] S1: Preparation of chlorinated 1-octadecenyl-3-ethanol imidazolium ionic liquid monomer:

[0029] N 2 For protection, add 3 parts of 1-ethanolylimidazole and 3.5 parts of 1-octadecenyl chloride into the reaction kettle, heat and reflux in a water bath at 60°C for 7h, extract with ether, remove unreacted 1-ethanolylimidazole, and then rotate at 70°C Evaporate for 2h to remove excess 1-octadecenyl chloride to obtain 1-octadecenyl-3-ethanol imidazolium chloride ionic liquid monomer.

[0030] The reaction equation is as follows:

[0031]

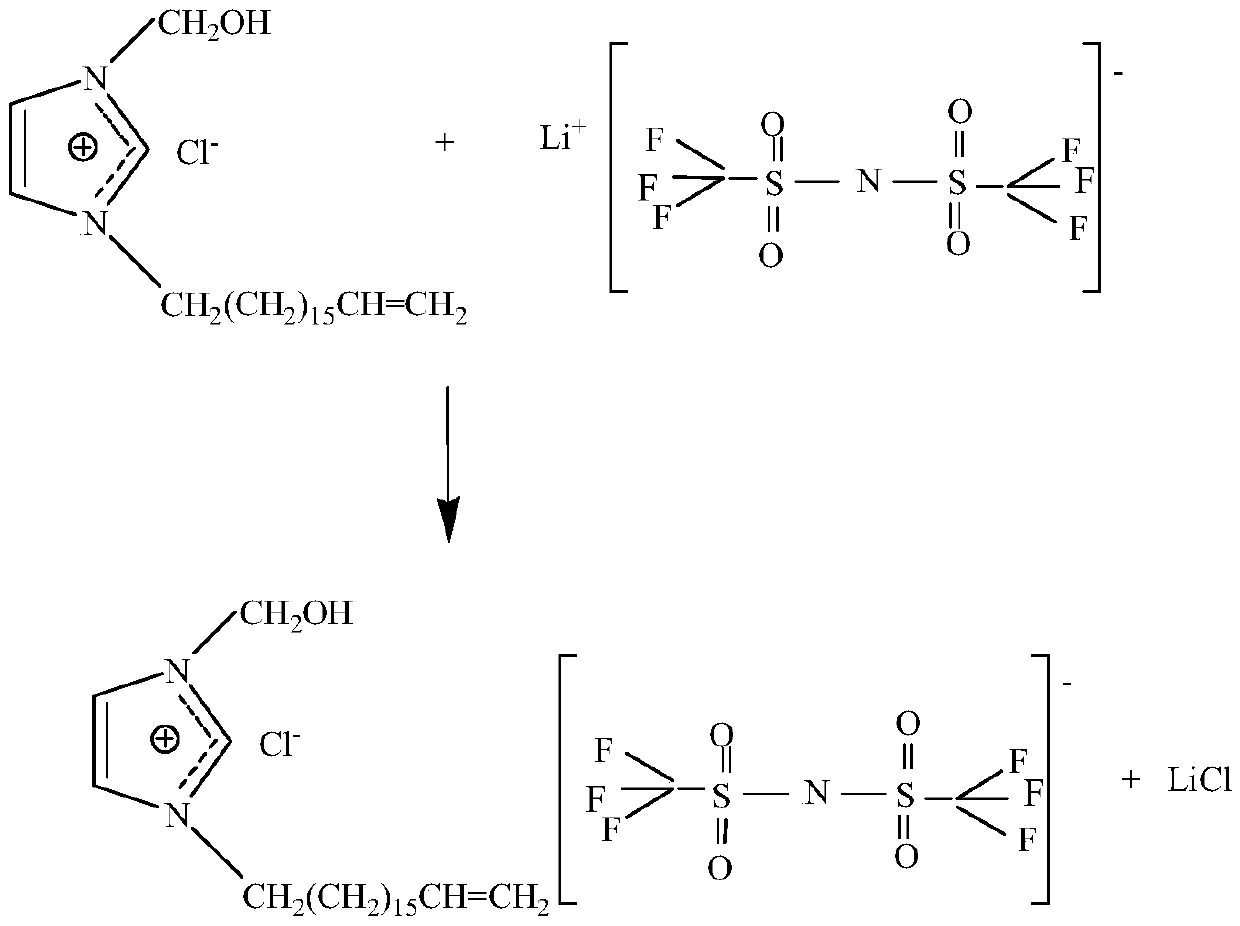

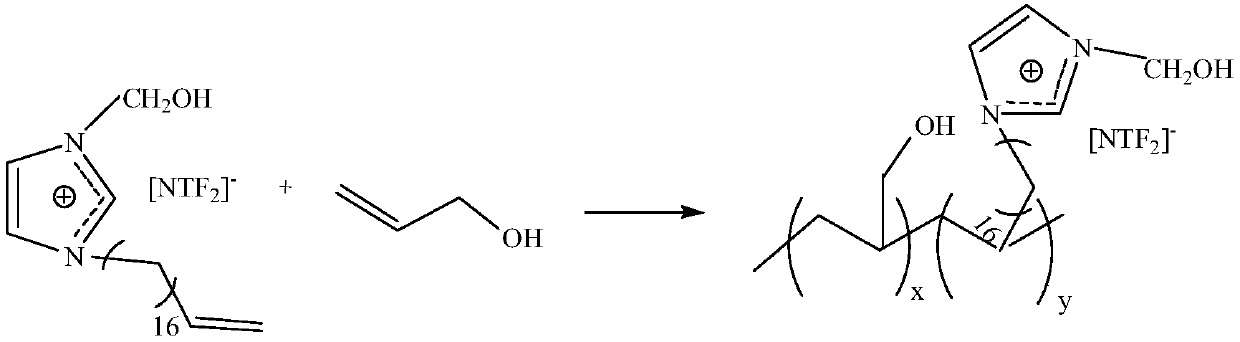

[0032] S2: Preparation of 1-octadecenyl-3-ethanol imidazole bistrifluoromethanesulfonimide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com