Novel organic silicon defoamer for landfill leachate treatment and preparation method of novel organic silicon defoamer

A technology of silicone defoamer and landfill leachate, which is applied in the field of defoamers, can solve the problems of affecting the defoaming effect of defoamers, demulsification, poor stability, etc. Foam suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

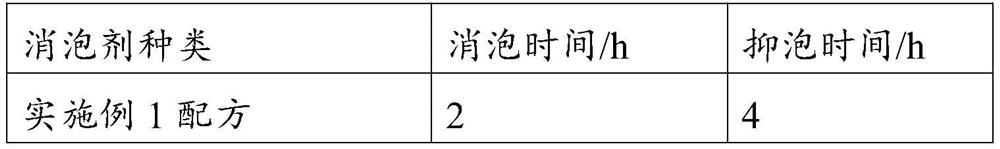

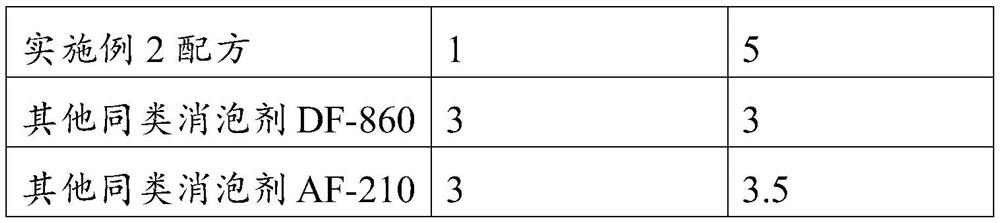

Examples

Embodiment 1

[0020] A new type of silicone defoamer for landfill leachate treatment, which is made of the following raw materials in parts by weight: 12 parts of polyether-modified polydimethylsiloxane with a viscosity of 600mPa.s; 2 parts of silicon, whose particle size is 15nm; 3 parts of amino-modified silicone oil; 3 parts of fatty acid polyoxyethylene ester, whose HLB value is 6.5; 5 parts of fatty alcohol polyoxyethylene ether; 2 parts of hydroxymethyl cellulose; 1 part of acid salt; 72 parts of deionized water.

Embodiment 2

[0022] A new type of silicone defoamer for landfill leachate treatment, which is made of the following raw materials in parts by weight: 18 parts of polyether-modified polydimethylsiloxane with a viscosity of 1200mPa.s; 4 parts of silicon, whose particle size is 20nm; 4 parts of epoxy modified silicone oil; 5 parts of polyoxyethylene fatty acid ester, whose HLB value is 9; 6 parts of propylene glycol block polyether; 4 parts of carbomer resin; 2 parts of quaternary ammonium salt parts; deionized water is 57 parts.

[0023] A method for preparing the organosilicon defoamer for the novel landfill leachate treatment of the above-mentioned embodiments, comprising the following steps:

[0024] Add polyether-modified polydimethylsiloxane, nano-scale fumed silica, and modified silicone oil into the reaction kettle, raise the temperature to 100-150°C, stir and react for 1-3h, and wait to cool to 40-50°C Finally, add fatty acid polyoxyethylene ester, stir for 30-40min to mix until uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com