Antifoaming agent containing organosilicone modified castor oil for PVA (Polyvinyl Alcohol) production and preparation method of antifoaming agent

A silicone modification, castor oil technology, applied in the direction of foam dispersion/prevention, can solve the problems of affecting the defoaming performance of the defoamer, difficult polyether preparation operations, complicated processes, etc., to improve the defoaming ability and suppress foam. The effect of strong ability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the organosilicon-modified castor oil defoamer that is used in the production of PVA of the present invention comprises:

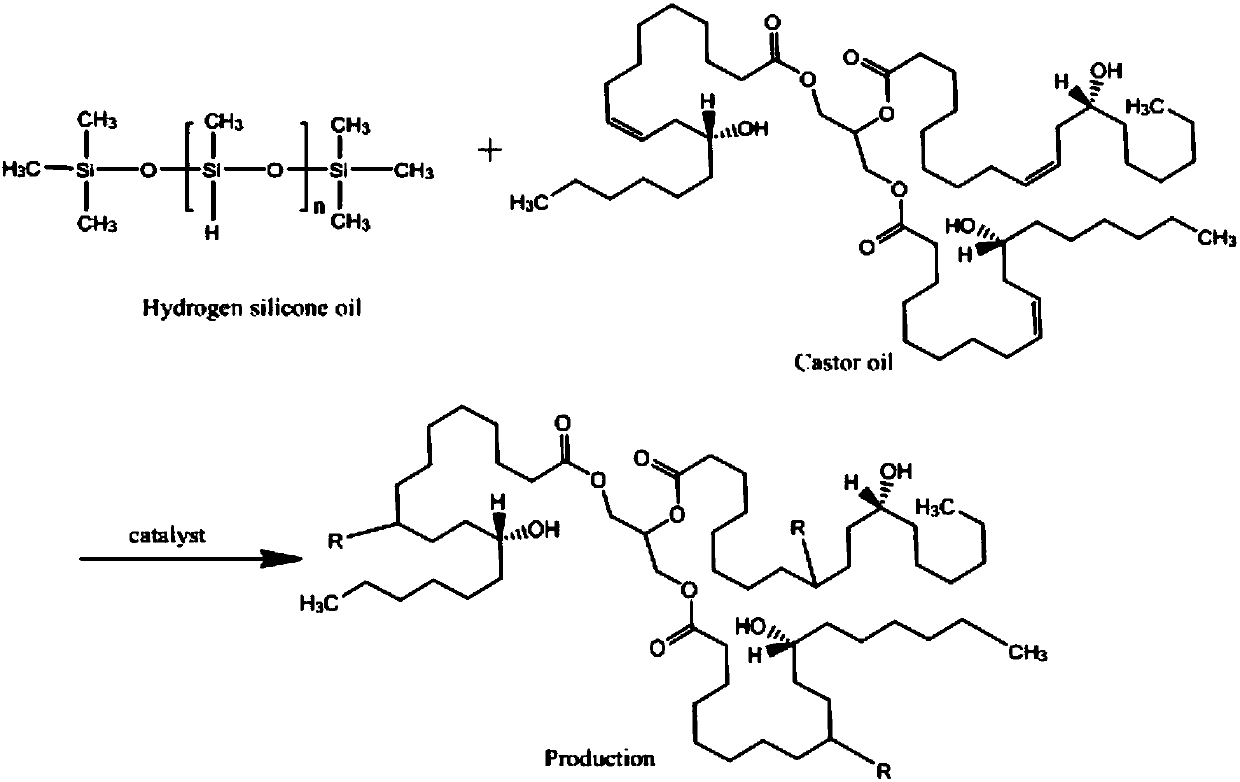

[0027] 1) First put the hydrogen-containing silicone oil and castor oil with a molar ratio of 1:0.5-2.5 in the reaction kettle, and stir for 20-30 minutes at a pressure ≤ -0.09MPa and a temperature of 80-95°C to remove water and low boiling point Impurity treatment, then add the chloroplatinic acid catalyst of total mass 0.01~1%, in N 2 In the air, heat up at 80-95°C and keep warm for 0.5-5h; react to obtain the active substance of silicone modified castor oil defoamer;

[0028] Among them, the hydrogen content of hydrogen-containing silicone oil is 0.05-0.2%.

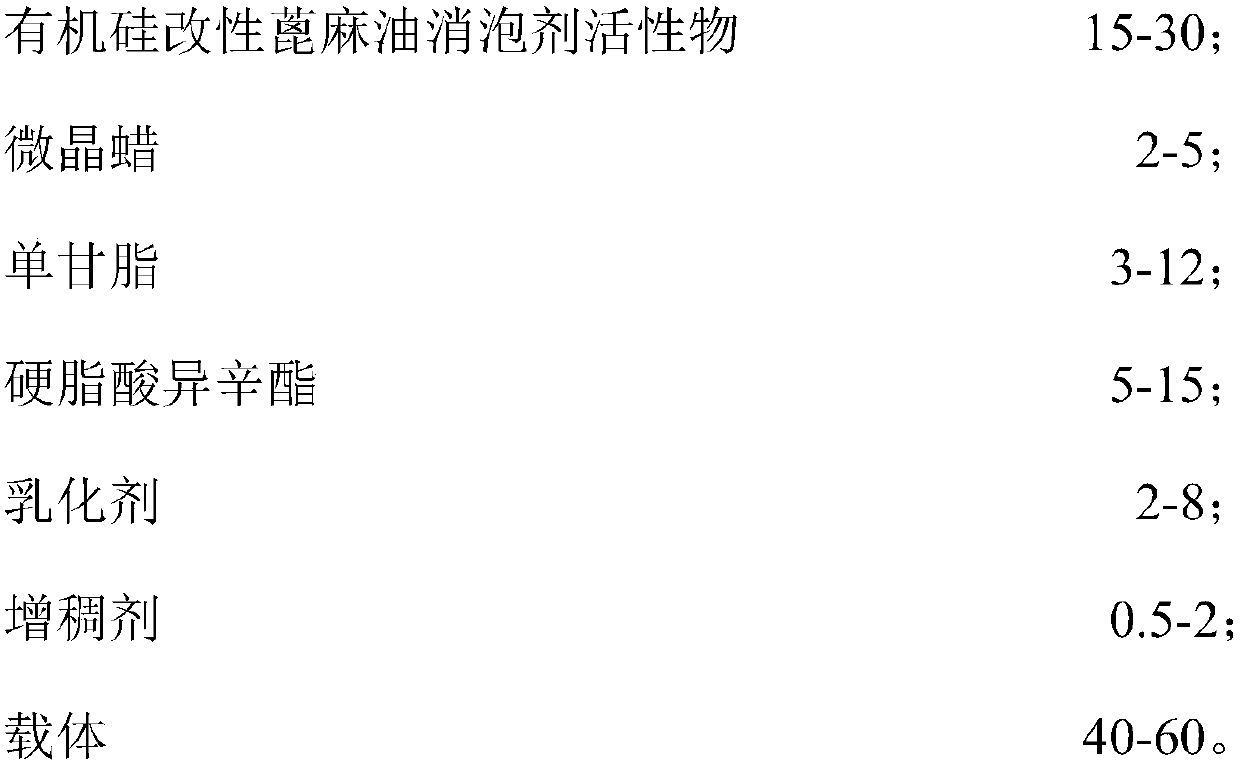

[0029] 2) According to the mass ratio of (15-30): (2-5): (3-12): (5-15): (2-8) to take the silicone modified castor oil defoamer active material, Microcrystalline wax, monoglyceride, isooctyl stearate and emulsifier are placed in the reaction kettle at a stirring ...

Embodiment 1

[0039] Put the hydrogen-containing silicone oil and castor oil with a molar ratio of 1:0.5 in the reactor, mix and stir, then put the system under pressure ≤ -0.09MPa, temperature 95°C, and stir for 20 minutes to remove water and low-boiling impurities, and then add The total mass of 0.1% chloroplatinic acid catalyst, in N 2 Raise the temperature in the environment and react to prepare the active substance of the defoamer and cool it out. Among them, the hydrogen content in hydrogen-containing silicone oil is 0.1%, and the ratio of hydrogen-containing silicone oil to castor oil is 1:0.5. 2 Then heat up at 80°C and keep it warm for 1.5h; finally, use the active hydrogen chemical titration method to detect the hydrogen content in the reaction system until the reaction conversion rate reaches more than 95%, that is, the silicone-modified castor oil defoamer active substance is obtained.

[0040] 2) Take 20g of silicone-modified castor oil defoamer active substance, 5g of microcr...

Embodiment 2

[0043] Put the hydrogen-containing silicone oil and castor oil with a molar ratio of 1:2.5 in the reactor, mix and stir, then put the system under pressure ≤ -0.09MPa, temperature 85°C, and stir for 30 minutes to remove water and low-boiling impurities, and then add The total mass of 0.01% chloroplatinic acid catalyst, in N 2 Raise the temperature in the environment and react to prepare the active substance of the defoamer and cool it out. Among them, the hydrogen content in hydrogen-containing silicone oil is 0.05%, and the ratio of hydrogen-containing silicone oil to castor oil is 1:2.5. 2 Afterwards, the temperature was raised to 85° C. and kept for 0.5 h; finally, the hydrogen content in the reaction system was detected by the active hydrogen chemical titration method until the reaction conversion rate reached more than 95%, and the organic silicon modified castor oil defoamer active substance was obtained.

[0044] 2) Take 25g of silicone-modified castor oil defoamer act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com