Defoaming agent for sewage treatment and preparation method thereof

A technology of sewage treatment and defoamer, which is applied in the direction of degassed water/sewage treatment, energy wastewater treatment, etc. It can solve the problems of high price, high operating cost, and large dosage of medicine, so as to eliminate a large amount of foam and improve the defoaming effect , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

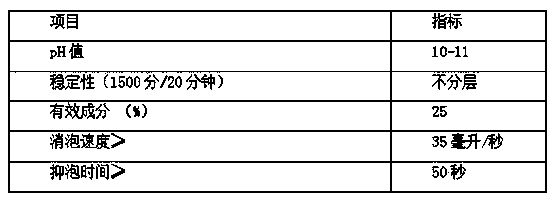

Image

Examples

Embodiment 1

[0039] A defoamer for sewage treatment, comprising the following components in parts by weight:

[0040] Diethanol glyceride 0.8 parts

[0041] 0.8 parts of ethylene bis stearamide

[0042] Heavy liquid paraffin 2.4 parts

[0043] Engine oil 40 parts

[0044] Kerosene 20 parts

[0045] 30 parts of simethicone

[0046] 1 part of white carbon black.

Embodiment 2

[0048] A defoamer for sewage treatment, comprising the following components in parts by weight:

[0049] Diethanol glyceride 1 part

[0050] 1 part ethylene bis stearamide

[0051] Heavy liquid paraffin 3.6 parts

[0052]45 parts of engine oil

[0053] Kerosene 25 parts

[0054] 32 parts of simethicone

[0055] 1.4 parts of white carbon black.

Embodiment 3

[0057] A defoamer for sewage treatment, comprising the following components in parts by weight:

[0058] Diethanol glyceride 0.9 parts

[0059] 0.9 parts of ethylene bis stearamide

[0060] 3 parts heavy liquid paraffin

[0061] Engine oil 42.5 parts

[0062] Kerosene 22.5 parts

[0063] 31 parts of simethicone

[0064] 1.2 parts of white carbon black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com