Method for producing concrete channel prefabricated part from mineral slag

A technology for concrete and prefabricated parts, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as hidden dangers of farmland water conservancy construction quality, influence of anti-seepage effect, deformation of water tank body, etc. Alkali-aggregate reactivity, effect of inhibiting alkali-aggregate reaction and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

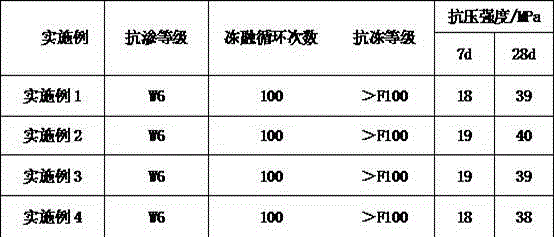

Examples

Embodiment 1

[0025] The method for utilizing slag to produce concrete trench prefabricated parts described in the present embodiment mainly comprises the following steps:

[0026] The concrete channel prefabricated part includes the following raw materials in parts by weight: wherein, 60 parts of coarse and fine aggregate, 20 parts of 42.5 sulfoaluminate cement, 10 parts of fly ash, 10 parts of slag micropowder, 3 parts of early strength agent, 3 parts of high-efficiency water reducer, 0.5 parts of defoamer, the high-efficiency water reducer is calcium lignosulfonate water reducer;

[0027] The production method of the prefabricated part of the concrete channel is: according to the ratio, mix the coarse and fine aggregate, 42.5 Portland cement, fly ash and slag powder, and then add the early strength agent, high-efficiency water reducer and defoamer Mix well with water, and the water-cement ratio is 0.50; install a formwork that has been padded with plastic film or coated with release oil ...

Embodiment 2

[0029] The method for utilizing slag to produce concrete trench prefabricated parts described in the present embodiment mainly comprises the following steps:

[0030] The concrete channel prefabricated part includes the following raw materials in parts by weight: wherein, 65 parts of coarse and fine aggregate, 15 parts of 42.5 sulfoaluminate cement, 6 parts of fly ash, 6 parts of slag micropowder, 2 parts of early strength agent, 2 parts of high-efficiency water reducer, 0.2 parts of defoamer, the high-efficiency water reducer is calcium lignosulfonate water reducer;

[0031] The production method of the prefabricated part of the concrete channel is: according to the ratio, mix the coarse and fine aggregate, 42.5 Portland cement, fly ash and slag powder, and then add the early strength agent, high-efficiency water reducer and defoamer Mix well with water, and the water-cement ratio is 0.46; Install a formwork that has been padded with plastic film or coated with release oil on...

Embodiment 3

[0033] The method for utilizing slag to produce concrete trench prefabricated parts described in the present embodiment mainly comprises the following steps:

[0034] The concrete channel prefabricated part includes the following raw materials in parts by weight: wherein, 68 parts of coarse and fine aggregate, 18 parts of 42.5 sulfoaluminate cement, 8 parts of fly ash, 8 parts of slag micropowder, 2 parts of early strength agent, 3 parts of high-efficiency water reducer, 0.4 parts of defoamer, the high-efficiency water reducer is calcium lignosulfonate water reducer;

[0035] The production method of the prefabricated part of the concrete channel is: according to the ratio, mix the coarse and fine aggregate, 42.5 Portland cement, fly ash and slag powder, and then add the early strength agent, high-efficiency water reducer and defoamer Mix well with water, and the water-cement ratio is 0.48; install a formwork that has been padded with plastic film or coated with release oil on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com