One-time low-temperature fast-firing light ceramic product and preparation process thereof

A light-weight ceramic and low-temperature technology, which is applied in the field of ceramic manufacturing, can solve the problems of high water absorption, low wear resistance of porcelain surface, and easy scratches, etc., and achieve good effect, good water resistance, and fast defoaming speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

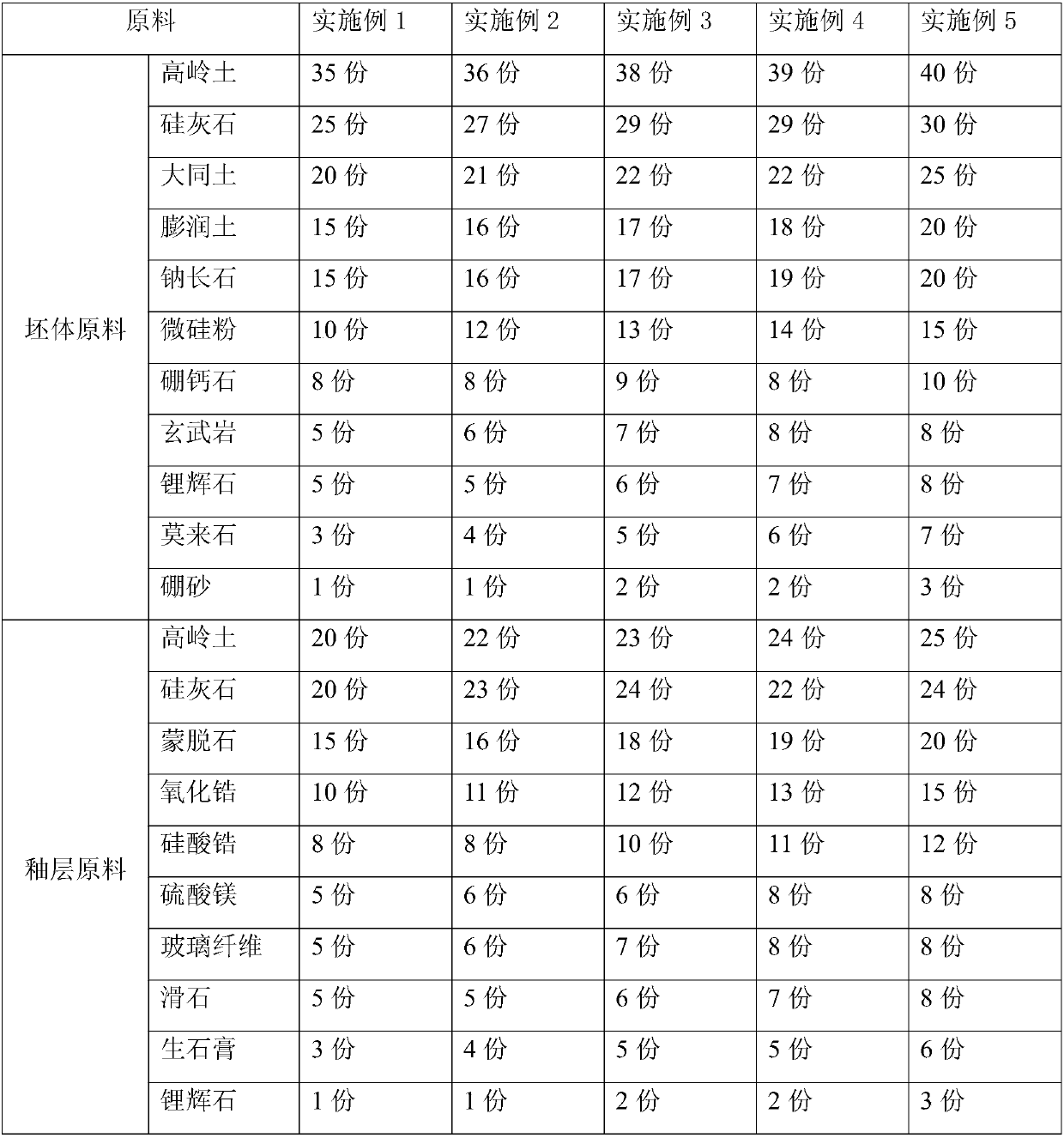

Embodiment 1

[0023] This embodiment provides a one-time low-temperature fast-fired lightweight ceramic product, including a green body and a glaze layer applied to the surface of the green body, characterized in that the raw material of the green body includes the following components by weight: 35 parts of kaolin, 25 parts of wollastonite, 20 parts of Datong clay, 15 parts of bentonite, 15 parts of albite, 10 parts of microsilica, 8 parts of boronite, 5 parts of basalt, 5 parts of spodumene, 3 parts of mullite, 1 part of borax Parts; the raw materials of the glaze layer include the following components by weight: 20 parts of kaolin, 20 parts of wollastonite, 15 parts of montmorillonite, 10 parts of zirconia, 8 parts of zirconium silicate, 5 parts of magnesium sulfate, glass fiber 5 parts, 5-8 parts of talc, 3 parts of raw gypsum, 1 part of spodumene, 1 part of fluorite, 1 part of actinite, 3 parts of copper-chrome black pigment.

[0024] This embodiment also provides a process for manufactur...

Embodiment 2

[0030] This embodiment provides a one-time low-temperature fast-fired lightweight ceramic product, including a green body and a glaze layer applied on the surface of the green body, characterized in that the raw material of the green body includes the following components by weight: 36 parts of kaolin, 27 parts of wollastonite, 21 parts of Datong clay, 16 parts of bentonite, 16 parts of albite, 12 parts of microsilica, 8 parts of boronite, 6 parts of basalt, 5 parts of spodumene, 4 parts of mullite, borax 1 part; the raw materials of the glaze layer include the following components by weight: 22 parts of kaolin, 23 parts of wollastonite, 16 parts of montmorillonite, 11 parts of zirconia, 8 parts of zirconium silicate, 6 parts of magnesium sulfate, glass 6 parts of fiber, 5 parts of talc, 4 parts of raw gypsum, 1 part of spodumene, 2 parts of fluorite, 3 parts of actinite, 5 parts of iron-zinc-chrome brown pigment.

[0031] This embodiment also provides a process for manufacturing...

Embodiment 3

[0037] This embodiment provides a one-time low-temperature fast-fired lightweight ceramic product, including a green body and a glaze layer applied on the surface of the green body, characterized in that the raw material of the green body includes the following components by weight: 38 parts of kaolin, 29 parts of wollastonite, 22 parts of Datong clay, 17 parts of bentonite, 17 parts of albite, 13 parts of microsilica, 9 parts of boronite, 7 parts of basalt, 6 parts of spodumene, 5 parts of mullite, borax 2 parts; the raw materials of the glaze layer include the following components by weight: 23 parts of kaolin, 24 parts of wollastonite, 18 parts of montmorillonite, 12 parts of zirconia, 10 parts of zirconium silicate, 6 parts of magnesium sulfate, glass 7 parts of fiber, 6 parts of talc, 5 parts of raw gypsum, 2 parts of spodumene, 2 parts of fluorite, 2 parts of actinite, and 9 parts of cobalt green pigment.

[0038] This embodiment also provides a process for manufacturing a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com