Water body-oriented low-COD defoaming agent non-toxic to microorganisms and preparation method of defoaming agent

A defoamer and microorganism technology, applied in the field of low COD defoamer for water body and its preparation, can solve the problems of increasing the COD content of water body, etc., and achieve the effects of long foam suppression time, high efficiency and reduction of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

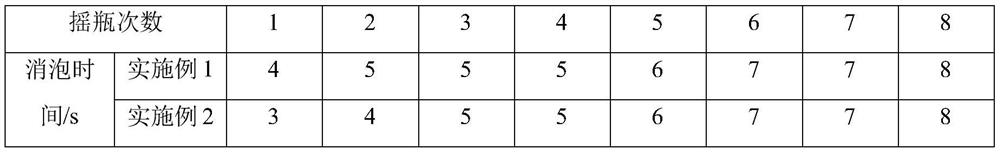

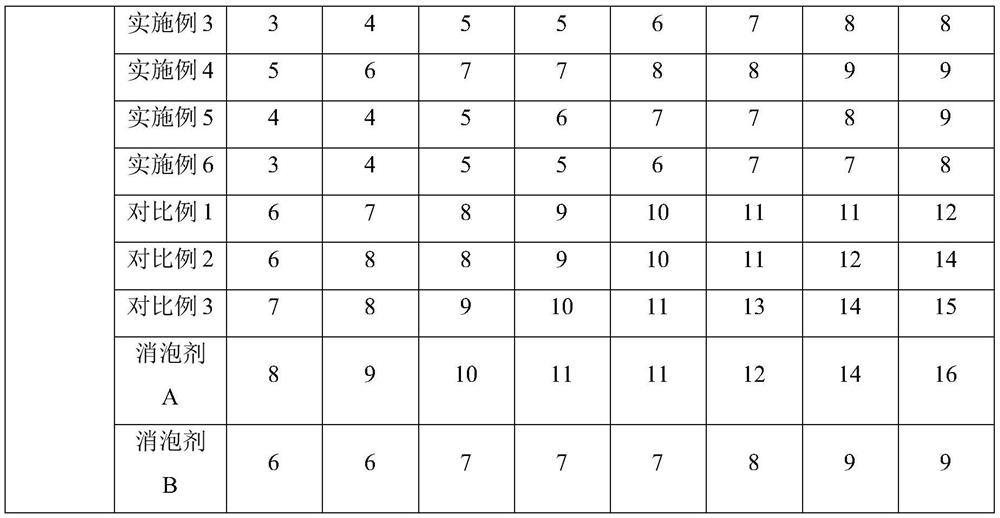

Examples

preparation example Construction

[0039] Water body among the present invention uses the preparation method of low COD defoamer, comprises the steps:

[0040] (1) Under the action of an acid catalyst, formic acid or acetic acid, hydrogen peroxide, and castor oil are heated and reacted. After the reaction, the product is moved into a separatory funnel to separate and obtain the upper oil phase, and the upper oil phase is washed with water and discarded. Phase, and then through alkali washing, water washing, and vacuum distillation to obtain epoxy castor oil; then add epoxy castor oil and amino silicone oil to the organic solvent, and then add a basic catalyst to it, and stir the reaction at 60-80°C for 8- After 12 hours, the supernatant was taken by centrifugation, and then the organic solvent was removed by rotary evaporation to obtain amino silicone oil modified epoxy castor oil.

[0041] (2) According to the ratio, add polydimethylsiloxane, mineral oil, amino silicone oil modified epoxy castor oil, hydrophob...

Embodiment 1

[0055] The preparation method of low COD defoamer for water body in the present embodiment is:

[0056] (1) Put formic acid, hydrogen peroxide, and castor oil in a reaction kettle with a molar ratio of 3:8:6, add concentrated sulfuric acid (1mol formic acid needs to be added with 0.3mL concentrated sulfuric acid), heat to 60°C, and react for 6 hours After the reaction, the product was transferred into a separatory funnel, and the upper oil phase was obtained by separation. The upper oil phase was washed with hot distilled water (50-60° C.), the water phase was discarded, and then neutralized by sodium hydroxide, and then washed with distilled water Distillation under reduced pressure after washing obtains epoxy castor oil; Then epoxy castor oil, amino silicone oil (mole dosage ratio is 1:3) is added in N, N dimethylformamide, then adds sodium hydroxide (1mol ring Oxygenated castor oil needs to be added with 0.5mL sodium hydroxide), stirred and reacted at 60°C for 12 hours, the...

Embodiment 2

[0059] The preparation method of low COD defoamer for water body in the present embodiment is:

[0060] (1) Put formic acid, hydrogen peroxide, and castor oil in a reaction kettle with a molar ratio of 3:10:8, add concentrated sulfuric acid (1mol of formic acid needs to be added with 0.5mL concentrated sulfuric acid), heat to 70°C, and react for 3 hours After the reaction, the product was transferred into a separatory funnel, and the upper oil phase was obtained by separation. The upper oil phase was washed with hot distilled water (50-60° C.), the water phase was discarded, and then neutralized by sodium hydroxide, and then washed with distilled water Distillation under reduced pressure after washing obtains epoxy castor oil; Then epoxy castor oil, amino silicone oil (mole dosage ratio is 1:5) are added in N, N dimethyl formamide, then add sodium hydroxide (1mol ring Oxygenated castor oil needs to be added with 1.0mL sodium hydroxide), stirred and reacted at 60-80°C for 8-12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com