Waterborne polyurethane paint and method for preparing same

A water-based polyurethane and water-based defoamer technology, applied in the field of coatings, can solve the problems of water resistance, salt spray resistance, salt water resistance, chemical resistance, impact resistance, abrasion resistance and weather resistance, etc. Good cutability and acid and alkali resistance, good compatibility and stable emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

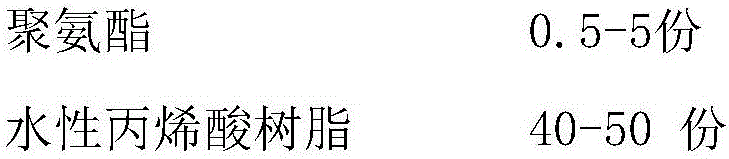

[0040] A water-based polyurethane paint, which is composed of component A and component B in a mass ratio of 5:1, and the component A is prepared from the following components in parts by weight:

[0041]

[0042] The B component is prepared from the following components in parts by weight:

[0043] 12 parts of water-based polyurethane curing agent

[0044] 5 parts of deionized water

[0045] Water-based defoamer 0.02 parts.

[0046] Its preparation method is:

[0047] (1) Mix and stir deionized water, co-solvent, water-based dispersant and half of the water-based defoamer according to the proportion; then add half of the water-based acrylic resin and polyurethane, pigments, and fillers for stirring;

[0048] (2) Grinding the mixture of step (1) by a sand mill to a fineness within 40 microns;

[0049] (3) Continue to stir the material in (2), and add the remaining water-based acrylic resin, water-based defoamer, surfactant, and anti-flash rust agent HZJ-601-4 in turn un...

Embodiment 2

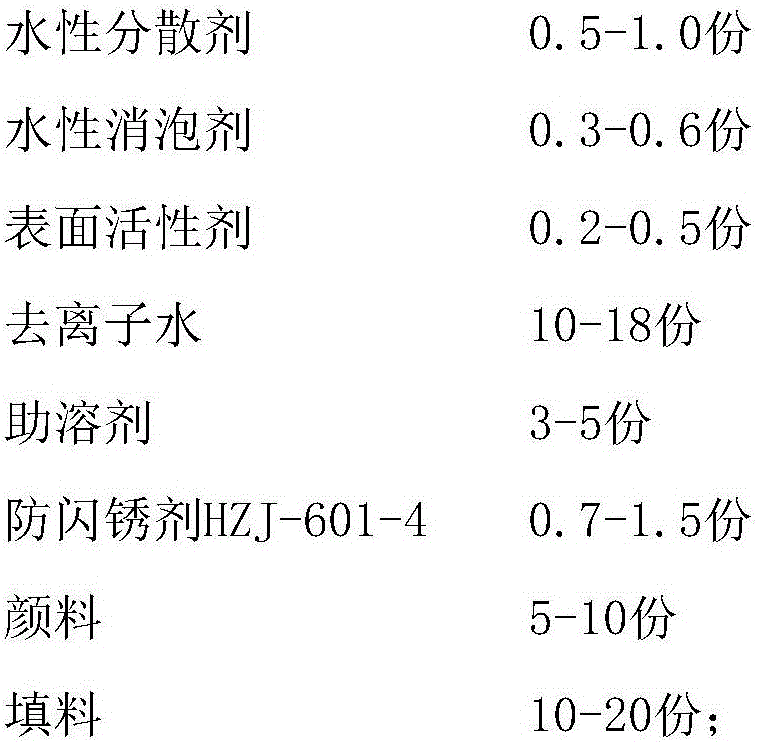

[0054] A water-based polyurethane paint, which is composed of component A and component B in a mass ratio of 5:1, and the component A is prepared from the following components in parts by weight:

[0055]

[0056] The B component is prepared from the following components in parts by weight:

[0057] 15 parts of water-based polyurethane curing agent

[0058] 8 parts deionized water

[0059] Water-based defoamer 0.05 parts.

[0060] Its preparation method is with embodiment 1.

Embodiment 3

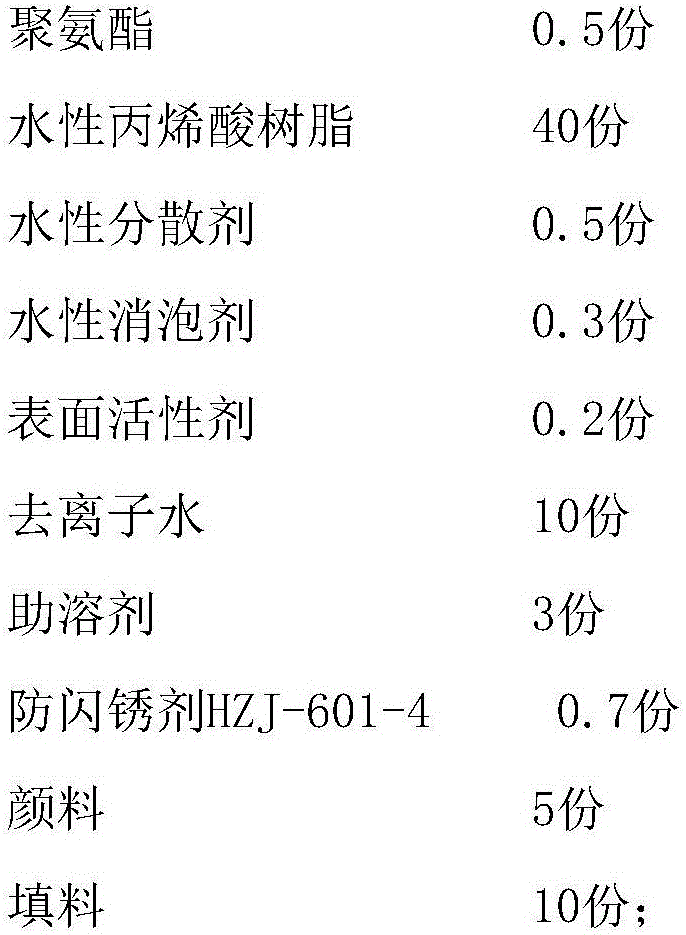

[0062] A water-based polyurethane paint, which is composed of component A and component B in a mass ratio of 5:1, and the component A is prepared from the following components in parts by weight:

[0063]

[0064] The B component is prepared from the following components in parts by weight:

[0065] 14 parts of water-based polyurethane curing agent

[0066] 6 parts deionized water

[0067] Water-based defoamer 0.03 parts.

[0068] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com