Defoaming agent for printing and dyeing wastewater

A technology for printing and dyeing wastewater and defoaming agent, which is applied in the direction of degassed water/sewage treatment, etc., can solve the problems of increasing the amount of auxiliaries and resources, the production cannot be carried out normally, and occupying processing space, etc., and achieves strong defoaming power and defoaming. The effect of fast speed and long anti-foaming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

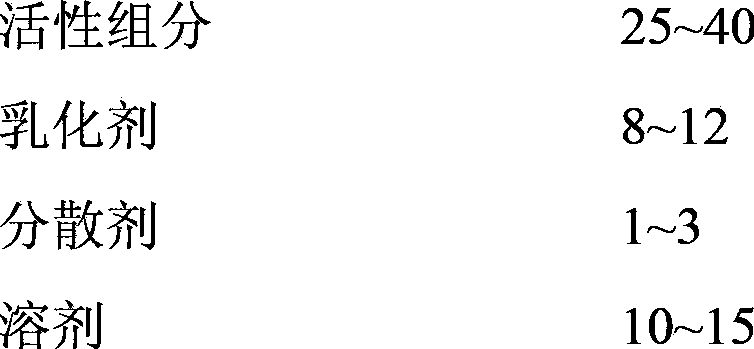

[0023] A defoamer for printing and dyeing wastewater, consisting of the following components by mass:

[0024]

[0025] In this embodiment, the active component is a mixture of simethicone, monoglyceride stearate and sodium carboxymethyl cellulose in a mass ratio of 1:1:1;

[0026] In this example, the emulsifier is Span-60.

Embodiment 2

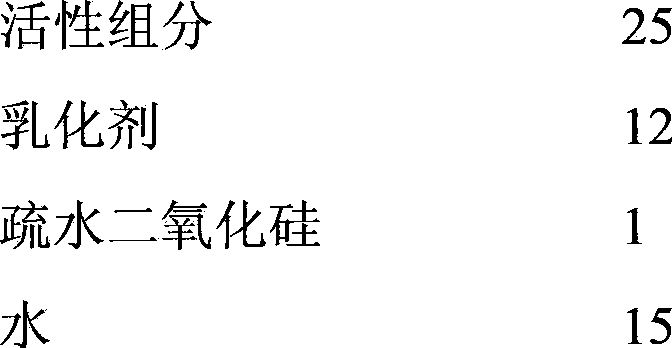

[0028] A defoamer for printing and dyeing wastewater, consisting of the following components by mass:

[0029]

[0030] In this example, the active component is a mixture of simethicone, monoglyceride stearate and sodium carboxymethylcellulose in a mass ratio of 5:3:3;

[0031] In this embodiment, the emulsifier is Tween-80.

Embodiment 3

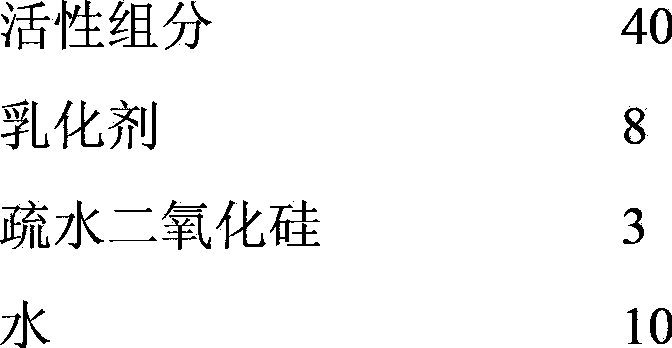

[0033] A defoamer for printing and dyeing wastewater, consisting of the following components by mass:

[0034]

[0035]

[0036] In this example, the active component is a mixture of simethicone, monoglyceride stearate and sodium carboxymethylcellulose in a mass ratio of 2:3:1;

[0037] In this embodiment, the emulsifier is Tween-20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com