Environment-friendly highly efficient mighty defoamer prescription and production process

An emulsion-type defoamer and defoamer technology, applied in the direction of foam dispersion/prevention, can solve problems such as easy explosion, poor emulsion stability, and poor initial defoaming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058]The invention also relates to a method for preparing the defoamer. Usually, the preparation process of the defoamer of the present invention is as follows: a certain amount of silicone oil, paraffin and auxiliary defoaming components are added to the reaction vessel in sequence, and after stirring and mixing (preferably stirring at a constant temperature of 80-100°C) 10-60 minutes), add a dispersant to disperse, and then add an emulsifier to emulsify (preferably add in several times, such as adding in 2-10 times). Then add deionized water at 70-95°C (preferably 80-90°C) to dilute, continue to stir evenly, and discharge after cooling to room temperature to obtain the defoamer of the present invention, which is usually milky white or slightly off yellow liquid.

[0059] Compared with the prior art, the defoamer of the present invention has the following main advantages:

[0060] 1. High surface activity, low surface tension, good defoaming effect, good initial defoaming ...

preparation Embodiment 1

[0067] Preparation of defoamer No.1

[0068] Take 8 parts of simethicone, 15 parts of liquid paraffin, and 8 parts of glycerin, and add them into the reaction kettle in the order of simethicone, liquid paraffin, and glycerin, and stir at a constant temperature of 80-100°C After 30 minutes, add 6 parts of polyisobutylene (weight-average molecular weight 3000) and continue constant temperature stirring for 20 minutes, add 10 parts of Tween-80 (Tween-80, produced by Shanghai Sanpu Chemical Co., Ltd.) in 5 times within one hour, and then Add deionized water at 80°C, stir at constant temperature for one hour, and then cool to room temperature to obtain 100 parts of milky white to yellowish defoamer.

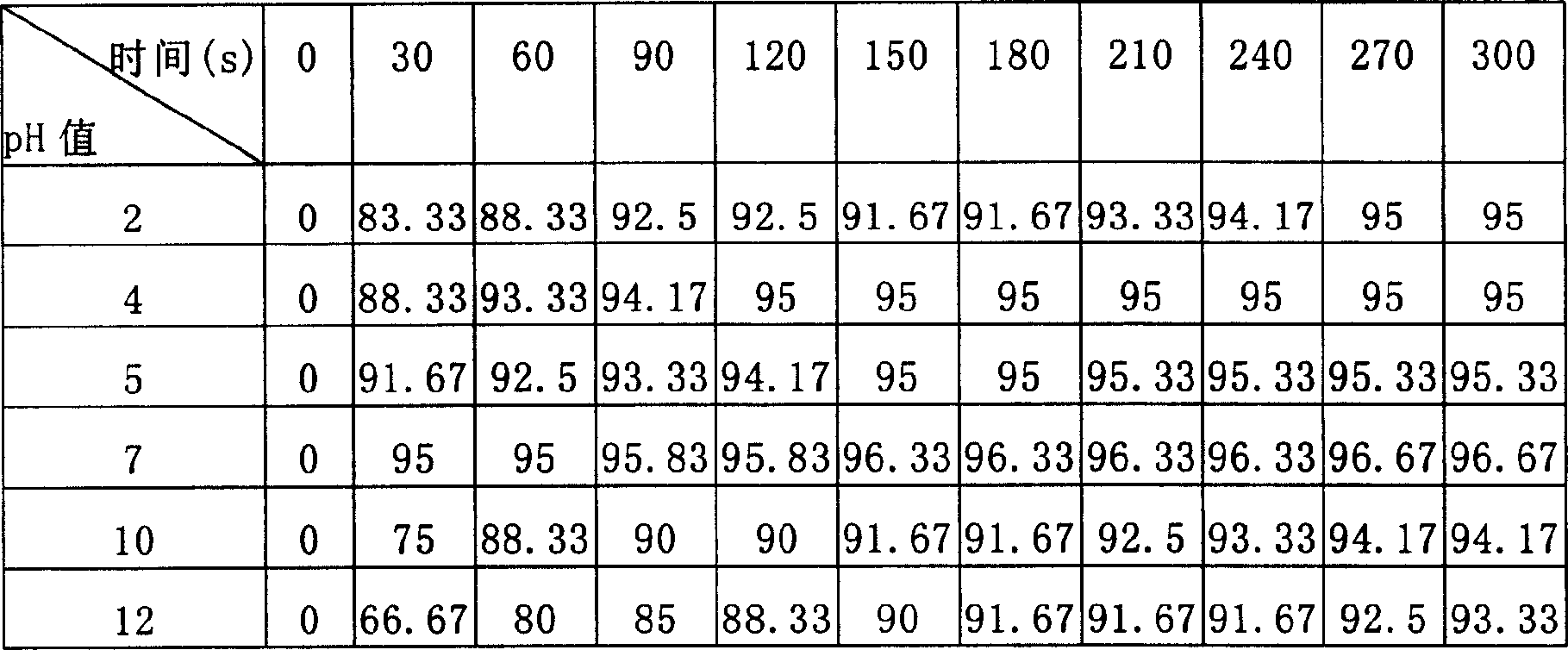

[0069] Test the defoaming efficiency of the defoamer with the following method: take 100 milliliters of 5% sodium dodecylbenzenesulfonate as a solution of the foaming agent, add the defoamer prepared above dropwise within 3 minutes (finally add 10 milliliters Defoamer), measure its v...

preparation Embodiment 2

[0072] Preparation of defoamer No.2

[0073] Take 19 parts of simethicone, 3 parts of liquid paraffin, and 10 parts of ethanol, and add them to the reaction kettle in sequence, and stir at a constant temperature of 80-100°C for 30 minutes, then add 3 parts of polyisobutylene (weight average molecular weight 2000 ) continue to stir at constant temperature for 20 minutes, and add 5 parts of emulsifier OP-10 (C 34 h 62 o 11 , produced by Shanghai Jingyan Chemical Technology Co., Ltd.), then add deionized water at 93°C, stir at constant temperature for one hour, and then cool to room temperature. That is to obtain 100 parts of antifoaming agent whose appearance is milky white and yellowish.

[0074] Measured by the same method as in Example 1, the results show that the defoaming efficiency of the defoamer No. 2 at 50° C. for 300 seconds is 97.93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com