A bulk type power plant desulfuration defoamer and a preparing method thereof

A technology of defoaming agent and power plant, applied in the field of defoaming agent, can solve the problems such as not being able to defoam for a long time, and achieve the effect of increasing emulsion stability, obvious thickening effect, and fast diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

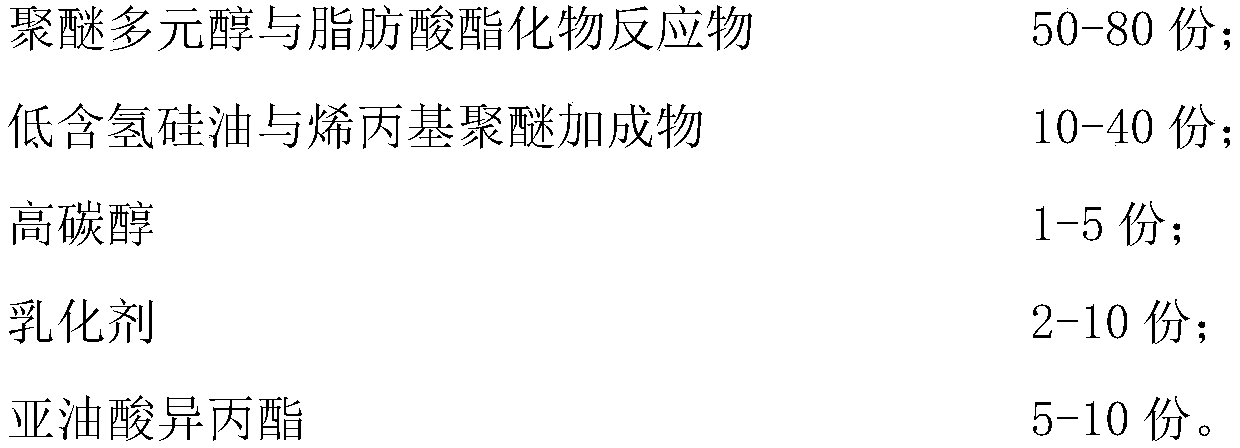

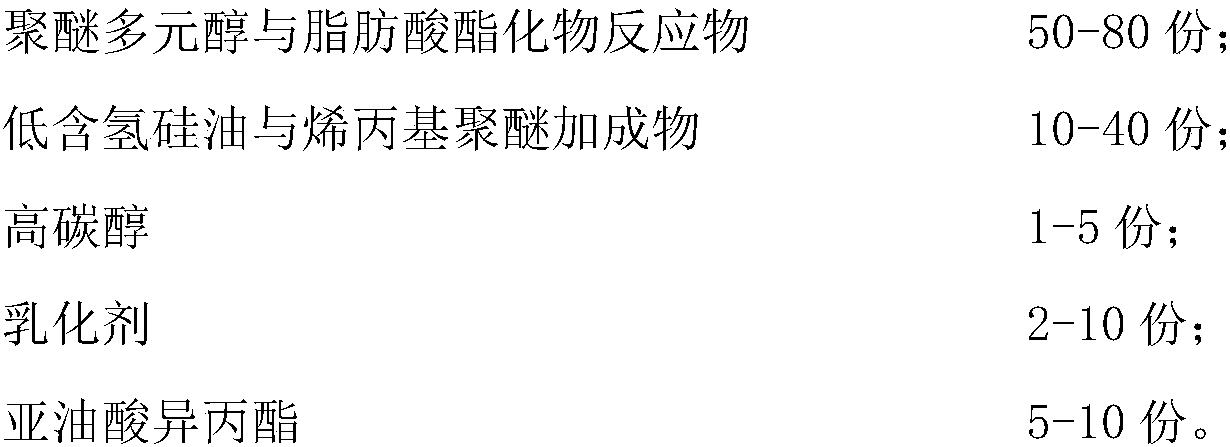

Method used

Image

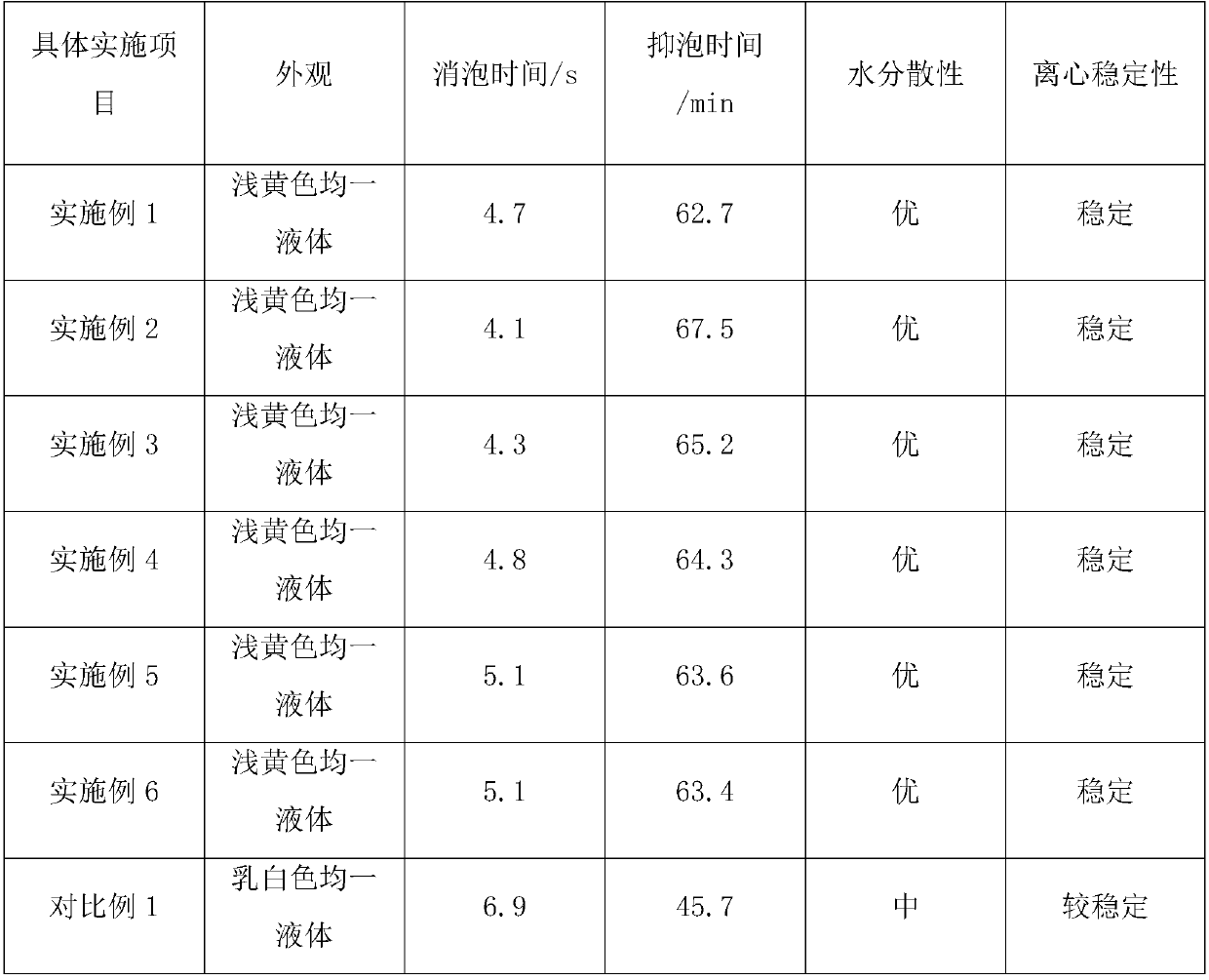

Examples

Embodiment 1

[0030] S1: Take polyether polyol L61100g, L62100g, fatty acid is stearic acid 16.7g in a 500ml three-necked flask, gradually warm up to 70°C until the stearic acid is completely dissolved, add 0.67g p-toluenesulfonic acid as an acidic catalyst, Stir and keep the temperature at 130-160°C for 4-8 hours, and remove the reacted water under reduced pressure to obtain the reactant of polyether polyol and fatty acid ester;

[0031] S2: Take 100g of low-hydrogen silicone oil with a hydrogen content of 0.08%, and 30g of allyl polyether with a molecular weight of 350 in a 250ml three-necked flask, stir and heat up to 80°C, and after vacuuming out the water contained in the raw materials, add 5ppm Platinum catalyst isopropanol, heat up to 130°C, after the material turns from turbid to transparent, keep it warm for 3 hours, then remove low boiling point substances under reduced pressure, and cool down naturally to obtain adducts of low hydrogen-containing silicone oil and allyl polyether ...

Embodiment 2

[0034] S1: Take polyether polyols PPG600100g, PPG1000100g, fatty acid is stearic acid 84.2g in a 500ml three-neck flask, gradually warm up to 70 °C until the stearic acid is completely dissolved, add 2.1g p-toluenesulfonic acid as an acidic catalyst, in the kettle Stir and keep the temperature at 130-160°C for 4-8 hours, and remove the reacted water under reduced pressure to obtain the reactant of polyether polyol and fatty acid ester;

[0035] S2: Take 100g of low-hydrogen silicone oil with a hydrogen content of 0.2%, and 30g of allyl polyether with a molecular weight of 350 in a 250ml three-necked flask, stir and heat up to 120°C, and after vacuuming out the water contained in the raw materials, add 20ppm Platinum catalyst isopropanol, heat up to 130°C, after the material turns from turbid to transparent, keep it warm for 3 hours, then remove low boiling point substances under reduced pressure, and cool down naturally to obtain adducts of low hydrogen-containing silicone oil ...

Embodiment 3

[0038] S1: Take 200g of polyether polyol GPE and 57.1g of stearic acid as the fatty acid in a 500ml three-neck flask, gradually raise the temperature to 70°C until the stearic acid is completely dissolved, add 1.43g of p-toluenesulfonic acid as an acidic catalyst, and keep stirring in the kettle React at a temperature of 130-160°C for 4-8 hours, and remove the reacted water under reduced pressure to obtain the reactant of polyether polyol and fatty acid ester compound;

[0039] S2: Take 100g of low-hydrogen silicone oil with a hydrogen content of 0.1%, and 30g of allyl polyether with a molecular weight of 350 in a 250ml three-necked flask, stir and heat up to 100°C, and after vacuuming out the water contained in the raw materials, add 10ppm Platinum catalyst isopropanol, heat up to 130°C, after the material turns from turbid to transparent, keep it warm for 3 hours, then remove low boiling point substances under reduced pressure, and cool down naturally to obtain adducts of low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com