Preparation method of defoaming agent for wastewater treatment

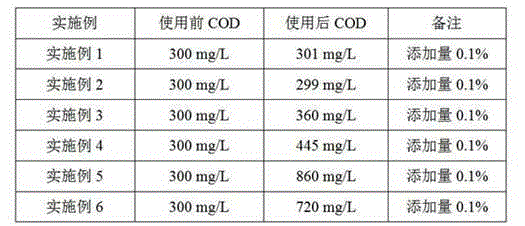

A waste water treatment and defoamer technology, which is applied in the direction of degassed water/sewage treatment, etc., can solve the problems of secondary pollution, increase of COD of waste water, etc., and achieve the goal of improving defoaming ability, long foam suppression time and improving dispersion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of defoamer for waste water treatment of the present invention, its preparation steps are as follows:

[0031] 1) Modification of silicone oil

[0032] Mix hydrogen-containing silicone oil and polyether, and use Speier catalyst to obtain polyether-modified silicone oil, and protect the entire reaction system with inert gas;

[0033] 2) Preparation of silicone paste

[0034] Mix hydrophobic silica and dimethyl silicone oil, heat and stir to make translucent silicone paste;

[0035] 3) Compounding of defoamer

[0036] The polyether-modified silicone oil prepared in step 1), the silicone paste prepared in step 2), and the emulsification aid are mixed with water, and stirred at a high speed to obtain a defoamer for wastewater treatment.

Embodiment 1

[0038] 1) Mix 50 grams of hydrogen-containing silicone oil with a molecular weight of 5000 and 60 grams of polyether with an EO / PO ratio of 0.5, add 0.4 grams of Speier catalyst, and react at a reaction temperature of 200°C for 8 hours to obtain a polyether-modified silicone oil for later use. The whole reaction system is protected with an inert gas;

[0039] 2) Mix 20 grams of hydrophobic silica and 160 grams of dimethyl silicone oil, heat to 50°C and stir to make a translucent silicone paste;

[0040] 3) Mix 40 grams of polyether-modified silicone oil prepared in step 1), 150 grams of silicone paste prepared in step 2), 50 grams of emulsifying aid and 760 grams of water, and stir at a high speed to obtain a defoamer for wastewater treatment agent.

Embodiment 2

[0042] 1) Mix 50 grams of hydrogen-containing silicone oil with a molecular weight of 6000 and 65 grams of polyether with an EO / PO ratio of 0.6, add 0.45 grams of Speier catalyst, and react at a reaction temperature of 250°C for 9 hours to obtain a polyether-modified silicone oil for later use. The whole reaction system is protected with an inert gas;

[0043] 2) Mix 20 grams of hydrophobic white carbon black with 180 grams of dimethyl silicone oil, heat to 50°C and stir to make a translucent silicone paste;

[0044] 3) Mix 60 grams of the polyether-modified silicone oil prepared in step 1), 100 grams of the silicone paste prepared in step 2), 100 grams of emulsification aids and 740 grams of water, and stir at a high speed to obtain a defoamer for wastewater treatment agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com