Self-emulsifying molecular antifoaming agent and preparation method thereof

A defoamer, molecular-level technology, applied in the field of molecular-level defoamer and its preparation, to achieve the effect of long antifoaming time, high cost performance and strong defoaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

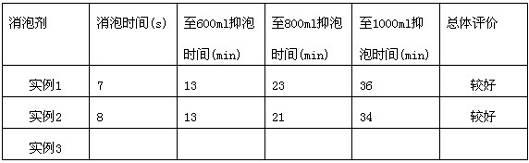

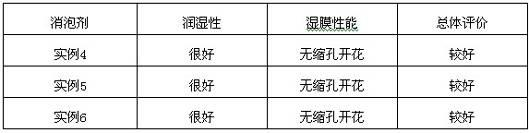

Embodiment 1

[0020] The antifoaming agent includes an antifoaming active substance and a dispersion medium, and the antifoaming active substance is 20% of the total mass, and the dispersion medium is 80% of the total mass, and the antifoaming active substance is composed of a high-grade fat with a mass ratio of 1:0.8:2:2 Alcohol, alkyne alcohol, polyether and silicone oil, the dispersion medium is n-arm linear polylactic acid (ns-PLLA-OH) with n=1; wherein, the active substance of higher fatty alcohol is isooctyl alcohol, and the alkyne The alcohol active substance is 2,5-dimethyl-3-hexyne-2-ynol, the glycerol polyether is polyoxypropylene glyceryl ether, and the silicone oil is methyl silicone oil.

[0021] The preparation method of the self-emulsifying molecular-level defoamer is as follows: the mass parts are 20 parts of active substances and 80 parts of star-shaped polymers, adding 50 parts of chloroform as a solvent, and 1 part of p-toluenesulfonyl chloride as an initiator. Raise the ...

Embodiment 2

[0023] The antifoaming agent includes the antifoaming active substance and the dispersion medium, and the antifoaming active substance is 40% of the total mass, and the dispersion medium is 60% of the total mass, and the antifoaming active substance is composed of high-grade fat with a mass ratio of 1:1.1:2.5:3 Alcohol, acetylenic alcohol, polyether and silicone oil, the dispersion medium is n-arm linear polylactic acid (ns-PLLA-OH) with n=3; wherein, the higher fatty alcohol active substance is 2-hexyldecanol, the The acetylenic alcohol active material is methyl butynol, the glycerol polyether is polyoxypropylene polyoxyethylene glyceryl ether, and the silicone oil is methyl trifluoropropyl silicone oil.

[0024] The preparation method of the self-emulsifying molecular-level defoamer is as follows: the mass parts are 40 parts of active substances and 60 parts of star-shaped polymers, adding 100 parts of chloroform as a solvent, and 1.5 parts of p-toluenesulfonyl chloride as an...

Embodiment 3

[0026] The antifoaming agent includes an antifoaming active substance and a dispersion medium, and the antifoaming active substance is 60% of the total mass, and the dispersion medium is 40% of the total mass, and the antifoaming active substance is composed of a high-grade fat with a mass ratio of 1:1.5:3:4 Alcohol, acetylenic alcohol, polyether and silicone oil, the dispersion medium is n-arm linear polylactic acid (ns-PLLA-OH) with n=6; wherein, the higher fatty alcohol active substance is 4-methyl-2-hexyl alcohol, the active substance of acetylenic alcohols is 3,5-dimethyl-1-hexyn-3-alcohol, the glycerol polyether is polyoxypropylene polyoxyethylene glyceryl ether, and the silicone oil is methyl Phenyl silicone oil.

[0027] The preparation method of the self-emulsifying molecular-level defoamer is as follows: the mass parts are 60 parts of active substances and 40 parts of star-shaped polymers, adding 150 parts of chloroform as a solvent, and 2.0 parts of p-toluenesulfony...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com